![The Refabricator [Image: NASA]](https://fabbaloo.com/wp-content/uploads/2020/05/refabricator_etu_open_pao-update_img_5eb091ee9128f.jpg)

3D printing has the potential to transform numerous industries.

From medicine to automotive, many sectors have felt the benefits of this technology and what it can do.

Additive manufacturing has been around for years, yet recently it has seen rapid advancements. Let’s explore this deeper.

Here’s the importance and potential of 3D printing.

Transforming Medicine

![3D printed pills [Image: FabRx]](https://fabbaloo.com/wp-content/uploads/2020/05/3d-printed-pills-by-fabrx_img_5eb091eeeaf9d.jpg)

The pharmaceutical industry is one that has seen significant development due to 3D printing. While the technology is yet to be adopted widespread across the sector, further advances will change this.

Much of the progress is still in its early stages, yet shows us an exciting glimpse into the future.

Drug Development

3D printing has found its place in drug development, allowing certain medicines to be manufactured more quickly and cheaply.

Alterations to certain prescriptions are much easier, such as dosages or salt forms.

One major milestone is controlled release. In the treatment of Parkinson’s disease, for example, this has been a massive step forward. Instead of having to take multiple different doses, the amount can be reduced as the concentration of the pills increases. Allowing a patient to take less medicine a day improves compliance, making them more likely to follow a treatment plan, so the benefits are clear.

3D printing has enabled this, as it allows scientists to make specific alterations to drugs much more easily.

Localised Production

Factory-based mass production has given way to localised, smaller-scale development. Pharmacies can now develop medicines on demand.

The results? This has the potential to revolutionise the supply chain, ensuring patients receive their drugs quicker while simultaneously lowering distribution cost.

Current Barriers

So, what’s preventing the widespread adoption of 3D printing in pharmaceuticals?

High production cost is one, further research needs to occur to help make the industry more economically viable.

To overcome these barriers, those within the industry need to utilise manufacturing collaborations and business opportunities available to them.

Impacting the Automotive Industry

![3D printed wheel [Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/hre3d2B-wheel-1_img_5eb091ef3b968.jpg)

Additive manufacturing is being increasingly utilised within the automotive industry. Recent advancements have allowed for newer, innovative designs and reduced costs.

Improving Fuel Efficiency

Additive manufacturing is allowing the automotive industry to develop more energy efficient components.

An example of this is shown by the University of Nottingham’s Functional Lattices for Automotive Components project. This was been funded by a grant from Innovate UK. The objective is to use 3D printing advanced technology to create more fuel efficient parts, while improving performance at the same time. This is essential as the automotive industry continues to implement carbon reducing strategies.

Reducing Weight

3D printing can reduce the weight of components by 40%-80% compared to the traditional subtractive manufacturing process. It does this by allowing components to be made with ducts that increase airflow.

This is because 3D printing adds the components in layers, which introduces more complex structures.

Lowering Cost

Production volumes in the automotive industry are extremely high, which can get costly.

Therefore, industrial printers are in high demand, as the speed they are able to print significantly increases output. This also simultaneously reduces labour costs, meaning the technology is accessible even from medium-sized companies.

Revolutionising Space Exploration

Space additive manufacturing is the new frontier for 3D printing, enabling the future of space travel and helping to grow the sector. Many projects are still prototypes, yet the potential for the technology is evident.

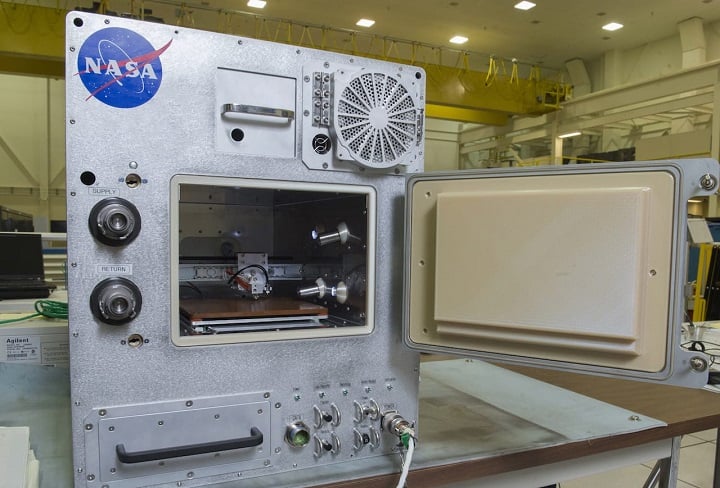

Manufacturing Tools

3D printing is transforming how astronauts can create tools and utensils. Developed for NASA, the Refabricator is able to recycle materials into usable items. It’s a recycler and 3D printer in one, used to manufacture medicinal tools; converting waste into printable materials.

Re-using items dramatically reduces cost, while ensuring those within the industry have the tools they need at their disposal.

It’s clear that 3D printing can help build the next generation of space systems.

Building Structures

After being approved by the European Space Agency, architects are now exploring the feasibility of using 3D printing to create buildings on the moon. Currently, 3D printers can build the lunar blocks at around 2m per hour, though this is set to increase as the technology advances. It’s predicted we’ll be able to print entire structures within a week.

3D printing could be the key to help us with interplanetary colonisation.

What’s Next?

We’ve only scratched the surface of what 3D printing can do. As the technology continues to make rapid developments, it will further transform numerous industries and sectors.

Healthcare 3D printing attempts to solve two problems that plague providing care: customization and cost.