![Medicinal tablets often have polymer structures to allow for controlled drug release [Source: Slideshare ]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0505e32a6f.jpg)

Last week we covered the announcement of EOS’ partnership with Merck Group to develop 3D printed medicinal tablets, but there’s a lot more to the story.

EOS Merck Tablet Project

The work being undertaken by EOS is to rework some of their 3D printers to enable the successful 3D printing of these tablets, which of course, are a combination of drug material compressed into tablet form.

I was unsure about this approach because I wondered how EOS would achieve this, as these drug materials were designed to be drugs, not to be used as binder in a normal thermoplastic 3D printing process. Somehow, I thought, EOS must be determining how to engineer these materials for printing; to make them act like the polymers normally used in 3D printing.

A daunting prospect, indeed.

Use Of Polymers In Pharmaceuticals

However, I received some feedback from those in the pharmaceutical community who insist that polymers are in fact used frequently in conventional tablet production.

I was, of course, curious about this usage as I’d never heard of polymers being in medicinal tablets. Have I been consuming polymers whenever I take my meds?

It turns out this is in fact the case. I found a fascinating slideshow that explains in some detail how polymers are used in the production of medicinal tablets.

As I suspected, the drugs are not normally used as structural elements in the tablets. Instead, food-safe biodegradable polymers are frequently used. The most frequently used materials are:

-

Poly(lactic acid)

-

Poly(lactic-co-glycolic acid)

-

Polyanhydrides

-

Poly(ortho esters)

-

Poly(phosphoesters)

Medicinal Tablet Design

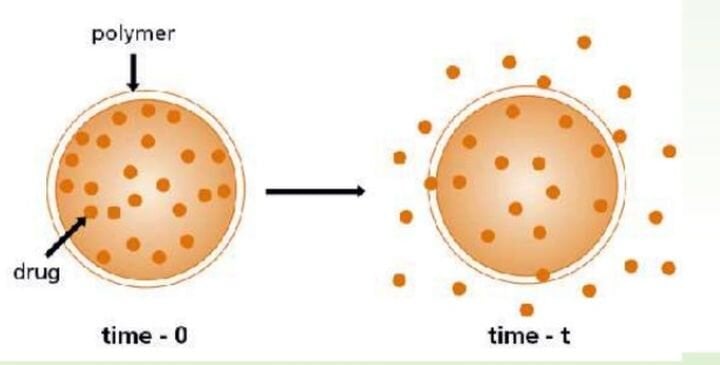

What do they do? They’re mostly used for three purposes: coating of the tablet, as a disintegrating agent and controlling the release of the drugs. This is done through a variety of ingenious methods.

One method involves allowing H2O to penetrate the tablet, where it slowly mixes with the drugs and carries some off to the rest of the body.

Another method involves a coating that is a porous membrane, which allows drugs to be released slowly. By designing the porous structure appropriately, one can achieve a desired release rate.

![The Osmotic Pressure technique for controlled drug release in medicinal tablets [Source: Slideshare ]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0505e50d44.jpg)

Yet another approach involves “osmotic pressure”, in which chemistry causes drugs to be slowly pushed out of the tablet into the body. There seem to be quite a few mechanical approaches for drug delivery.

How is all this achieved? It seems that the materials are used as building blocks. Some are considered binders, while others are for surface coatings, and yet others are designed to dissolve. These are simply assembled in the right configuration to allow the function of the tablet to take place.

After the drugs have been deployed, what happens to the polymers? They are in fact designed to disappear. Either a hydrolytic approach (where they simply dissolve in H2O) or an enzymatic approach (where they are broken down by enzymes) is done, and before long these polymers are simply gone.

This is what happens today in the pharmaceutical industry, where tablets of all types are made every day. Now, back to the EOS project.

Future 3D Printed Pills

Imagine the limitations the tablet designers must face, as they can only do relatively simple maneuvers to “build” a tablet. They can compress material, coat material and not much else. The magic must be in the mixes of the materials: a porous surface might be made by mixing a material that dissolves with one that doesn’t.

Now imagine a world where the tablet designers are able to fully design mechanical structures to achieve far more functional mechanisms by the use of 3D printing. This could be a revolution in tablet production similar to what has happened in the aerospace industry, where new parts are radically different from their now-primitive predecessors.

We could be looking at a future of smart tablets.

Via Slideshare