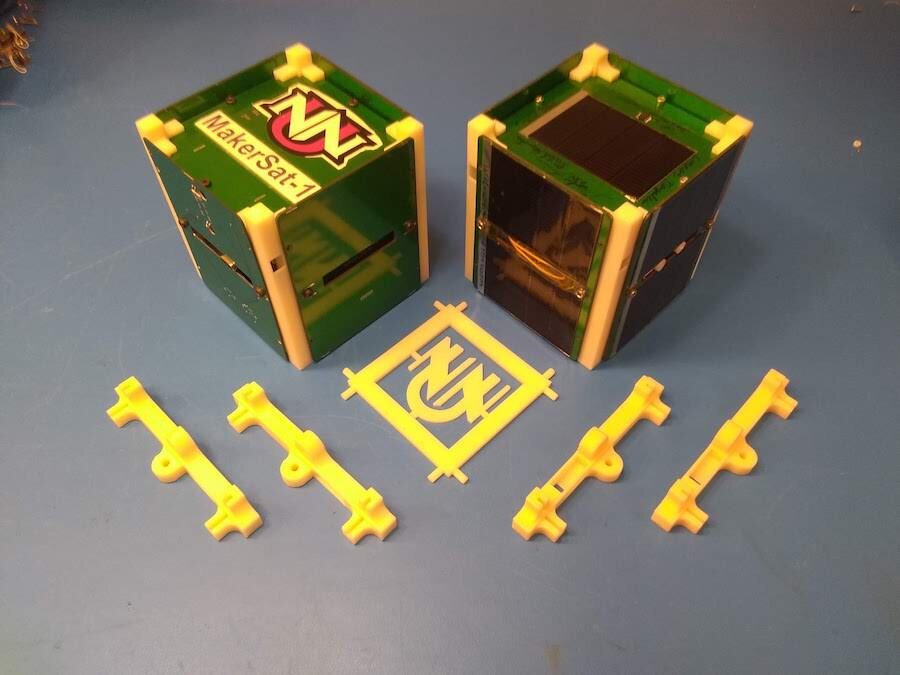

![The MakerSat-1 CubeSat [Image: Stephen Parke, NNU]](https://fabbaloo.com/wp-content/uploads/2020/05/makersat-1_img_5eb0505d8c45c.jpg)

Years of experimentation are leading to affirmation: 3D printing in space, for in-space use, is looking viable.

CubeSats are relatively bitty satellites with consistent sizing used to get scientific payloads into space. These nanosatellites have also incorporated scientific testing into their making through use of 3D printed structures since at least 2011.

Also under scientific scrutiny has been actually 3D printing in space. The appropriately-named Made In Space has been working toward this end with a 3D printer (the Additive Manufacturing Facility — AMF) installed on the International Space Station (ISS).

In 2017, the AMF created parts for the MakerSat-1, designed by students from Northwest Nazarene University (NNU). The MakerSat-1 was among a slew of experimental small satellites released into space last month from the ISS.

Made In Space reports:

“The mission is the first demonstration of an object 3D printed in orbit being implemented into a functioning satellite. MakerSat-1 will provide important insight into how radiation in space affects the durability of 3D printed plastic. The nanosatellite began sending data to ground teams shortly after its release.”

3D Printing In Space

Some of the first noteworthy in-space 3D printing was for use by astronauts, such as the famed wrench that NASA was proud to say was “emailed” to the ISS in 2014.

Spare parts production is a major use for an onboard 3D printer, as digital inventories offer the ability to reduce the weight of just-in-case spare parts, a significant consideration in close quarters (and with significant cost to getting every additional ounce into space in the first place).

But that’s not the only use — in-space 3D printing is also being explored for 3D printing for space. Made In Space says:

“As seen with the MakerSat-1 mission, AMF is able to manufacture the structural frame of CubeSats in space. Once additional hardware components arrive at ISS, CubeSats can be quickly assembled quickly by astronauts before the devices are deployed. MIS is developing new capabilities that would enable printing of electronics on orbit, alleviating the need for those CubeSat components to be launched.

…AMF reduces the wait time for mission critical assets from months to hours. It also eliminates the need for a rocket to transport, lowering mission cost.”

3D printing and assembling the CubeSats allows for great dexterity in experimentation, as astronauts can respond effectively in real time to rising needs in various studies.

Of course, Made In Space is also concerned with larger-scale efforts such as with its NASA-funded Archinaut project for structural 3D printing.

By starting small, and continuing to prove out those smaller-scale experiments to validate more aspects of spaceworthy 3D printing, Made In Space is taking the steps needed to ensure that all realities are studied and understood.

Via Made In Space