![A face shield with 3D printed visor [Image: PolyU]](https://fabbaloo.com/wp-content/uploads/2020/05/polyumask_img_5eb050653c011.jpg)

Coronavirus is on the rise, and so are efforts to deploy 3D printing to combat infection.

COVID-19, the current global incarnation of coronavirus, has been raising headlines around the world. Awareness is on the rise as more cases spread. We’ve seen some impact on the 3D printing industry already, as it like many others has seen events cancelled to forestall potential exposure.

Cancellations are not the only intersection between COVID-19 and 3D printing, however, as the technology is increasingly being deployed to help.

Personal Protection Against Coronavirus

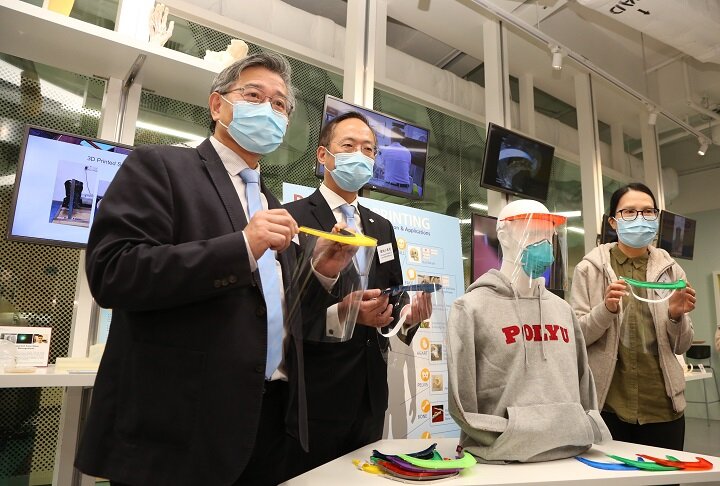

Last week, the Hong Kong Polytechnic University (PolyU)’s University Research Facility in 3D Printing (U3DP) announced its latest effort in the fight against viral spread: personal protective equipment (PPE).

PPE is of particular importance in hospital environments, but that’s certainly not the only place. Many private individuals the world over have been buying stores out of their face masks and other shielding equipment to try to keep their germs to themselves and limit exposure to outside contaminants. Such a sharp uptick in buying has led to a natural decrease in supplies — leading many hospitals to develop shortages where they’re needed most.

Working in collaboration with Queen Elizabeth Hospital for 3D printed eye shields and with the Hospital Authority to create 3D printed face shields, PolyU is getting all of its U3DP equipment in on the effort.

![Desktop 3D printing for face shields [Image: PolyU]](https://fabbaloo.com/wp-content/uploads/2020/05/polyumakerbot_img_5eb050655cb2f.jpg)

Some of the primary advantages of 3D printing come into play here, namely speed of design and development. According to PolyU, “From design, to mould-making, and finally to production took just a fortnight.” Over a ten-day period, 3D printers operating around the clock created 700 eye shields and more than 800 face shields.

“With support from the local manufacturing industry with which PolyU has strong connections, the production of face shields has been increased to 10,000 pieces per day starting from today [28 February], and will reach 30,000 pieces per day by late March. It is hoped that this steady supply of face shields will help meet the imminent needs of Hong Kong’s frontline medical personnel,” PolyU notes.

![3D printed face shield pieces ready for assembly [Image: PolyU]](https://fabbaloo.com/wp-content/uploads/2020/05/polyu3dp_img_5eb05065ac3a9.jpg)

Another advantage of 3D printing comes in here in terms of materials, as Professor HC MAN, Dean of the Faculty of Engineering, Director of University Research Facility in 3D Printing, PolyU, explains:

“Since the face shield is a one-off disposable item, we chose a less expensive PLA filament material to develop the 3D printed frame and attached it with a plastic clear film. We also leveraged the studies of our School of Design in the comparison of head size between Asians and Westerners in order to design a face shield that better fits Chinese wearers.”

Awareness of specific needs, from protection to disposability to sizing, came into play as the team at PolyU designed the made-in-Hong-Kong PPE. 3D printed visors are fitted with plastic sheets to form the face shields, which are designed to be worn together with standard face masks for improved protection.

PolyU and Coronavirus

![[Image: PolyU]](https://fabbaloo.com/wp-content/uploads/2020/05/polyumasks_img_5eb05065d1448.jpg)

The 3D printed PPE is by no means PolyU’s only effort in combating COVID-19.

The institution is also offering new means of monitoring the spread of disease with a new data analytics platform, sending students and alumni to Wuhan to help frontline medical personnel, and cancelling its face-to-face coursework in favor of safer e-learning and educational recess “until it is safe” to resume in-person interaction.

Another standout in terms of PolyU’s efforts is a new automated diagnostic system for point-of-care testing for an impressive array of illnesses:

“In one single test and within approximately one hour, the System can identify 30 to 40 pathogens including seasonal influenza viruses, such as influenza A subtypes H1, H2 and H3, avian influenza viruses H5, H7 and H9, human respiratory syncytial virus, severe acute respiratory syndrome coronavirus (SARS-CoV), Middle East respiratory syndrome coronavirus (MERS-CoV) and 2019-nCoV,” PolyU says.

3D Printing and Coronavirus

While the most obvious ties between 3D printing and COVID-19 have to date been regarding events, we’re sure to see increasing deployment of the technology to actively safeguard populations.

3D printing is often put to use in medical applications including a good amount of point-of-care usage. Diagnostics, protective equipment, and patient care tools are frequently being 3D printed, expanding lower-cost medical care to more populations. When all that is needed is low-cost PLA and a MakerBot, PPE and other goods can be made just about anywhere on demand.

Source: PolyU

1 comment