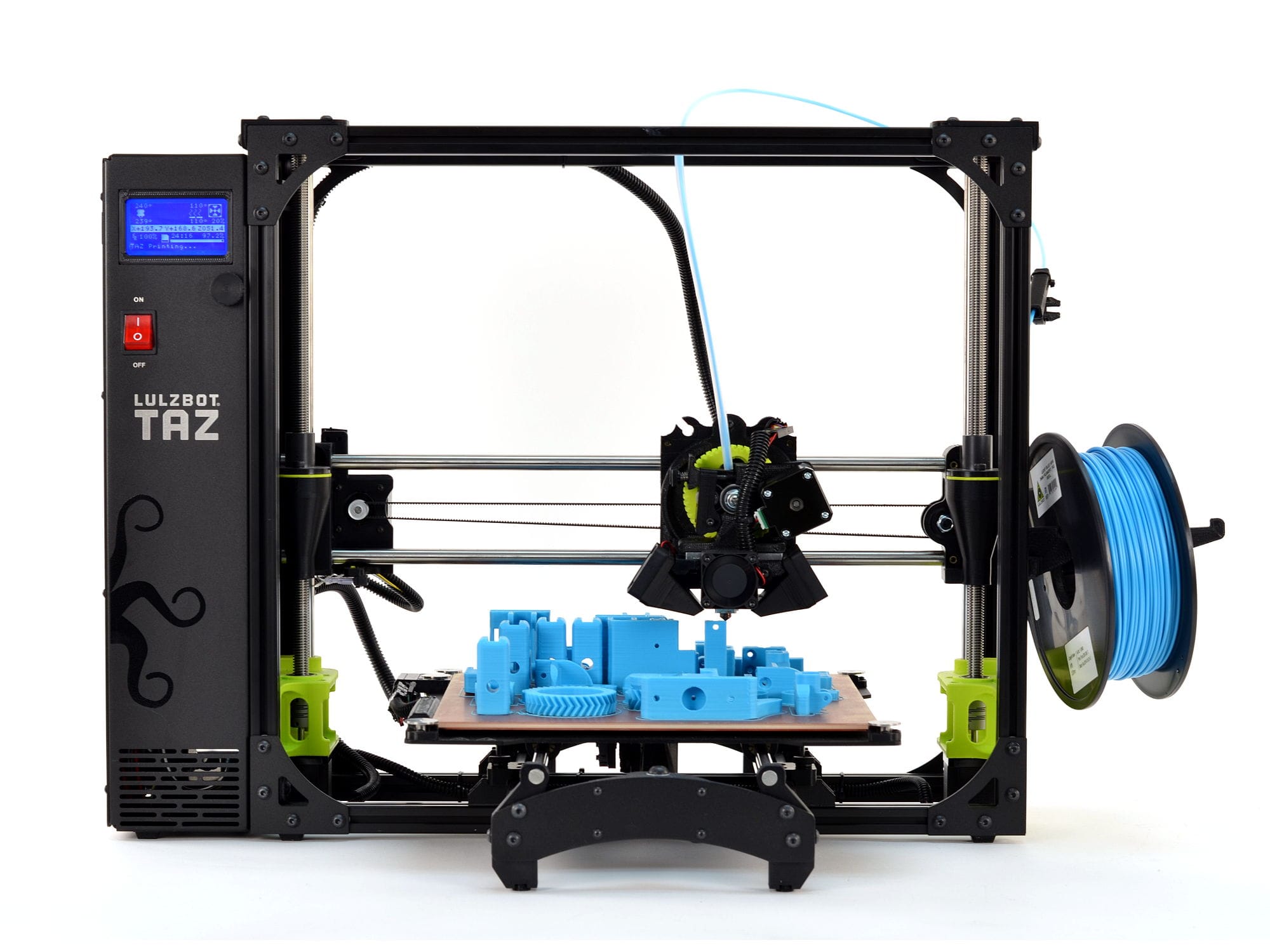

![The TAZ 6 3D printer is used by the military [Source: Aleph Objects]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb094f805c8e.jpg)

We learned something very interesting about the LulzBot TAZ 6.

The TAZ 6 was the flagship desktop 3D printer from Aleph Objects, at least until the recent announcement of the TAZ Pro, which combined the innovations of the TAZ 6 with new features to make the device even more robust.

What we learned is that apparently the TAZ is is considered by some branches of the US military to be a standard device, and is used in the field, according to an Aleph Objects spokesperson.

We did ask if the TAZ 6 was bombproof, but it apparently isn’t, as you might guess. However, we were told that it can very easily be broken into two parts, making it much easier to transport. I then imagined a soldier quickly breaking down the machine and stuffing it into a pack for a secret project in a remote area.

That vision is apparently true, as the Aleph Objects spokesperson told us that the military often jumps out of airplanes with their TAZ 6 securely packed.

I had no idea this type of activity was taking place with a common 3D printer. The TAZ line has been known for its robustness, but having the device used directly by the military on missions pretty much proves the case.

What might the military be doing with a nearly-portable 3D printer in the field? The answer is likely printing parts. The benefit is that if there are mechanical breakdowns in various equipment, there would be no need to bring quantities of spare parts. Instead, the spares, or at least some of them, could be 3D printed onsite with the TAZ 6.

Field Use Of 3D Printers

That would require the unit to bring with them any digital 3D models required to produce the spares, but it’s also possible the 3D models could be transmitted over radio link if needed. Of course, they would also have to bring a sufficient supply of 3D printer filament.

What material is used? I suspect ASA might be a useful material in this scenario, as it is relatively easy to print, is reasonably strong, or at least strong enough to consider being used for mechanical parts, and is resistant to UV light, which is no doubt a requirement for field work. It’s also possible they may use PLA simply for ease of printing for parts that are not exposed to the elements.

This capability would be of particular use if the mission had very limited contact to base. Soldiers could easily 3D print parts onsite, on demand, without any assistance from the supply department.

Remote 3D Printing

It’s certainly an interesting use case for 3D printing, but demonstrates the value the military puts on this approach. What could be of value to everyone, however, is to find analogous situations in the non-military world. I believe there are many remotely located operations that could surely benefit from this.

But, like many established businesses today, they may not have access to the 3D models required to produce the replacement parts.

Foiled once again by lack of 3D models.

Healthcare 3D printing attempts to solve two problems that plague providing care: customization and cost.