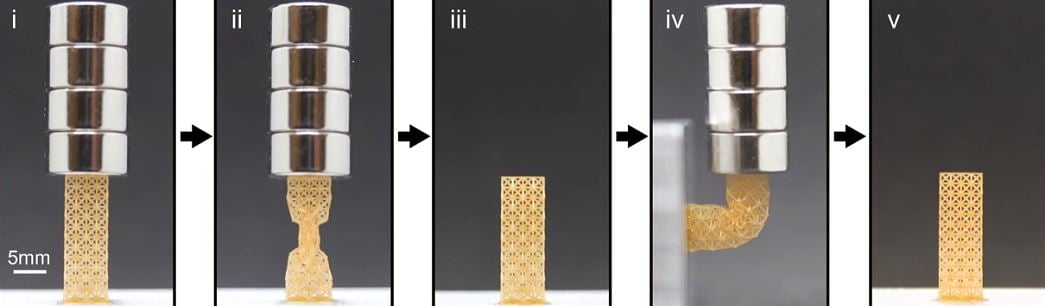

![The metamaterial holding a load, being reshaped, and reverting to its original form [Image: Rutgers University–New Brunswick]](https://fabbaloo.com/wp-content/uploads/2020/05/rutgers4d_img_5eb099a25d9e0.jpg)

Just as we start to build comfort with 3D printing, scientists throw another dimension at it: another look at 4D printing.

4D printing adds the dimension of time to the now-familiar length, width, and height of a build. Building time in to a print is no simple feat, of course, and that means 4D printing remains mostly a lab process today. Time changes a build, as environmental conditions can trigger a change — usually through temperature adjustments that bring about different characteristics.

“4DP is an opportunity to create future technology-based products that could disrupt industries. Shape-shifting materials have already been leveraged on a small scale in the automotive, aerospace, defense and medical industries. Initially, the examples of ‘what’s possible’ will be technology-focused. Understanding the business opportunities and revenue impacts will take longer,” Research Vice President, Additive Manufacturing at Gartner Pete Basiliere told me in a recent trends discussion of forward-looking trends.

Research is being undertaken around the world in this futuristic adaptation of additive manufacturing. Recently, Rutgers University–New Brunswick engineers shared their latest look into 4D printing.

“Imagine smart materials that can morph from being stiff as wood to as soft as a sponge – and also change shape,” they begin.

Their research is presented in a paper called “4D printing reconfigurable, deployable and mechanically tunable metamaterials,” published in Materials Horizons.

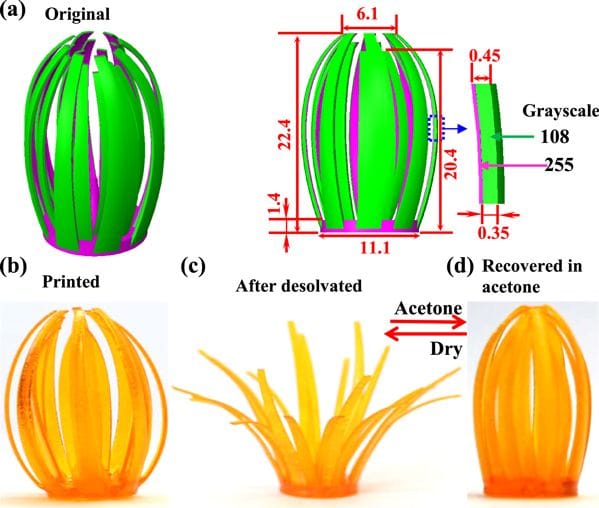

They focus on metamaterials, an increasingly interesting area where internal structures introduce different engineering properties. 4D printing with metamaterials introduces the ability to tune metamaterials: these changeable properties can be adjusted to fit conditions, allowing objects to adapt to their surroundings.

“Using digital micro 3D printing with a shape memory polymer, dramatic and reversible changes in the stiffness, geometry, and functions of the metamaterials are achieved,” the paper’s abstract notes.

Many areas are actively exploring usage for 4D printing. Applications for adaptable objects are many; the Rutgers team is focusing on shock absorption, morphing wings for airplanes or drones, soft robotics, implantable biomedical devices.

“We believe this unprecedented interplay of materials science, mechanics and 3D printing will create a new pathway to a wide range of exciting applications that will improve technology, health, safety and quality of life,” said senior author Howon Lee, an assistant professor in the Department of Mechanical and Aerospace Engineering.

Metamaterials in this study can see stiffness “adjusted more than 100-fold in temperatures between room temperature (73 degrees) and 194 degrees Fahrenheit, allowing great control of shock absorption.” This is where that initial sponge/wood interplay comes into the picture.

The team showcases their materials’ morphing in a video (by Chen Yang/Rutgers University–New Brunswick):

As with most 4D printing research to date, the work remains in the lab at this point. Per Gartner’s latest look ahead from Basiliere, 4D printing remains more than 10 years out from the Plateau of Productivity.

Still, with more research coming out from across the world, that future looks like it will have some promising new capabilities to bring to 3D printing.

Via Rutgers