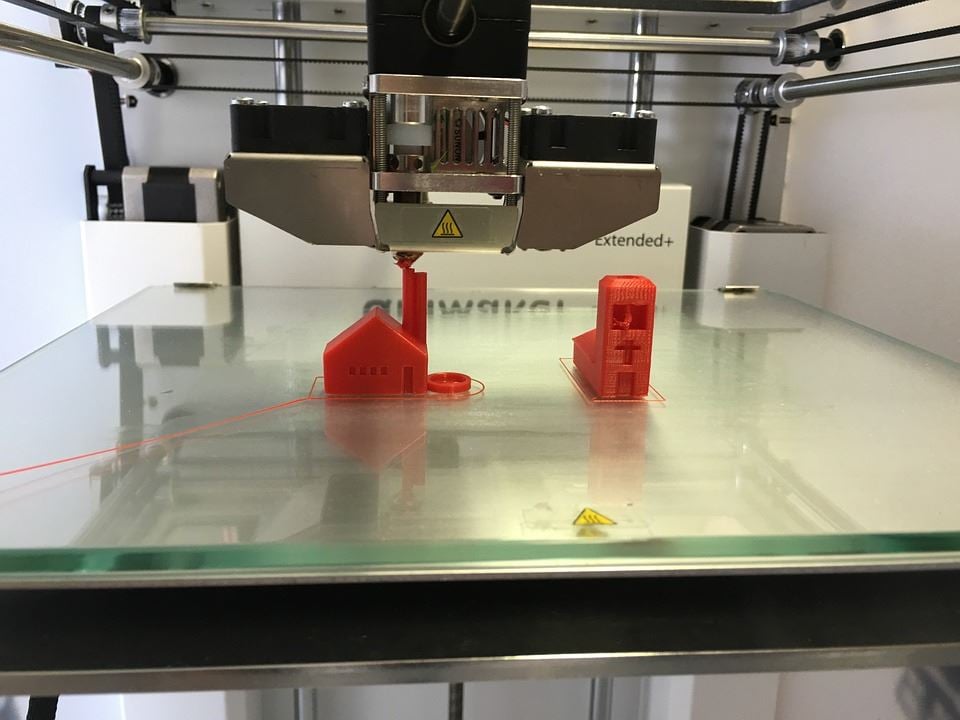

![[Image: Pixabay ]](https://fabbaloo.com/wp-content/uploads/2020/05/printer-1455166_960_720a_img_5eb096fc7187d.jpg)

With recent advances in technology, 3D printing is fast becoming popular. According to a recent report, the 3D printing market is set to double in size every three years with the annual growth forecasted by analysts generally estimated between 18.2% and 27.2%. It also states that SMEs are the power-users of online 3D printing services, representing more than 75% of the global customer base.

In other words, 3D printing technology is no longer the domain of specialty shops or people with deep pockets. As the technology becomes more affordable, an increasing number of individuals and small business owners are taking advantage of it. A 3D printer may become a common household appliance just like a microwave or a refrigerator.

However, it isn’t a plug-and-play product. So, whether you are a beginner or a seasoned 3DIY-er, buying the right 3D printer can seem like a daunting task. Here are six essential factors that you should consider when selecting a 3D printer.

Choose the Right Printing Technology

Not all 3D printers will use the same printing technology. Here are a few of the most popular polymer printing technologies along with strengths and weaknesses.

-

Fused Deposition Modeling (FDM)

FDM is the easiest and most common printing technology. It is also known as Fused Filament Fabrication (FFF) or Plastic Jet Printing (PJP). In this process, a printer typically prints an object in successive layers by extruding a continuous length of printing material (like ABS or PLA filament) through a heated nozzle. So, the printing begins at the bottom and works its way upwards.

-

Stereolithography (SLA)

SLA uses a special liquid plastic printing material called photopolymer resin. Usually, an ultraviolet laser solidifies layer after layer of printing material to create the part. SLA-based 3D models have incredibly high resolution. The process is also faster than FDM and SLS. It’s a popular choice for model builders and designers. However, it is an expensive process and requires additional post-processing steps, like washing and curing, in addition to standard support removal and other finishing work.

-

Selective Laser Sintering (SLS)

SLS uses a laser to melt and fuse powdered raw materials such as silicates, polystyrene or even metal to print an object. It can produce high details while printing. As a result, it is an excellent choice for industrial design applications. However, it is the most expensive of these printing technologies.

Find the Compatible Material

A filament is a 3D printing material that looks like a long cable, used for extrusion-based 3D printing processes, the most popular technology used in lower-cost desktop machines. You can find dozens of different types of printing materials out there.

However, ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid) are the two most common filaments. As both materials are thermoplastics, you can heat and cool them repeatedly to obtain the desired 3D shape.

-

ABS

Derived from fossil fuels, ABS is durable, strong, and offers high-temperature resistance. So, it is a favorite among professionals such as mass manufacturing 3D parts for finishing. However, it gives off a strong smell like burning plastic. Also, it is non-biodegradable.

-

PLA

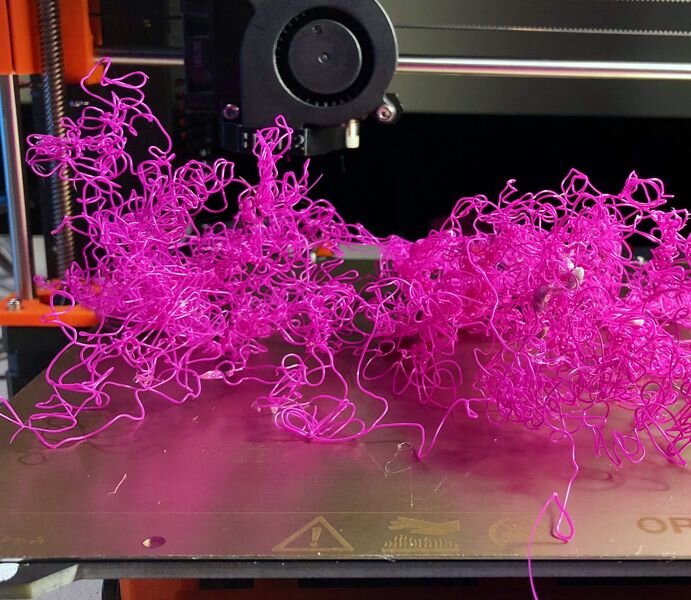

Produced from renewable resources such as sugarcane or corn, PLA is biodegradable. You can also print objects with thin layers and sharp corners using PLA. It is available in varied colors. As a result, many hobbyists and individuals prefer it over ABS. However, it is known to be prone to clogging as it can be stringy, and is not the most robust material available. Both ABS and PLA are usually available as filaments or spools of 1.75mm or 3mm.

-

Others

You can also choose from other options including Nylon, Resin, Wood (a blend of recycled wood and a binding polymer), HIPS (High Impact Polystyrene), PVA (Polyvinyl Alcohol), Carbon Fiber, ASA (Acrylic Styrene Acrylonitrile), and many more, including metals. Engineering-grade plastics, metals, and other more specialty materials will require more robust machines (e.g., high-temperature 3D printers, hardened nozzles).

Determine the Size of the Object You Want to Print

The size of the objects you want to print can help determine the build volume you look for in the 3D printer you select. Build volume is the maximum print size of a printer. It is usually indicated in inches or millimeters. Typically, large build volume will allow you to print big objects.

Unfortunately, most desktop printers (primarily designed for hobbyists) have lower or moderate build volume (maximum 380 x 380 x 380 mm). Most printers also fall short of their registered Z-axis dimension. So, you need to choose accordingly.

CADzilla, a 3D printer, made by Australia-based Studio Kite is perhaps one of the largest ones out there. It has a build volume of 2600 x 2600 x 3600 mm or 8.5 x 8.5 x 11.8 feet. It is 3x larger than the VX4000 (4000 x 2000 x 1000 mm), which is one of the largest and most renowned 3D printers.

Keep in mind too that build volumes can also be overcome by printing a large object in several parts that can be joined together when finished.

Consider the Printing Speed

Printing speed is also an essential factor. It is, in general, inversely proportional to the resolution. Higher resolution means more details, which in turn, requires slower printing speed. For example, printing a shoe will take considerably longer than creating a baseball.

The quality and configuration of the print head will also affect the printing speed. For instance, a small nozzle will produce superfine prints, but at a slow printing speed. On the other hand, a large nozzle will work quickly, but it will compromise the print quality.

When it comes to printing speed, FDM is usually slower than the SLA technology. UNIZ, well-known makers extremely speedy 3D printers, released its SLA Slash 2 series, with which the company broke its own record by setting the new highest printing speed at 1200mm/hour.

Think About Your Skill Level

3D printing is a complex and emerging technolo

gy. It will take you some time to master even the most user-friendly 3D printer. You will need to learn about the various settings in the slicing software such as picking up the right printing material and choosing the optimal printing speed depending on your project. You will also need to understand the strengths and limitations of your printer.

Many 3D printers are available, with both fully assembled and kit forms popular. Kits require assembly, which requires some technical know-how, but are often significantly cheaper

So, if you haven’t used a 3D printer before, you should try the most basic desktop models first, and work your way up as your skills develop. It is in your best interest not to overestimate your technical skills. If you don’t know how to use a printer, you will spend more time and money repairing it than using it. That’s why it also helps to have someone experienced enough to guide you through the process.

Find a Suitable Location for the Printer

Lastly, you should keep the 3D printer in a convenient but safe location. Keeping it indoors, preferably in a dust- and dirt-free environment, is a good idea. You should also keep it away from the reach of children and pets. You don’t want any accidents to happen, damaging this expensive machine and getting someone injured in the process.

You will need to have proper ventilation to ensure good air flow for health considerations and for mitigating unpleasant smells. Large printers will need to be set up outside your house or office, probably in a separate room. Make sure to check the user manual and machine specifications before setting it up.

You will also need to store your printing material in a humidity-free environment. Most printing materials will inherently attract water molecules present in the air. This will alter the quality of your 3D filament and may also damage your printer. You can create a DIY humidity free storage using transparent plastic file boxes or storage boxes. There are plenty of other filament storage solutions available online.

Wrap Up

3D printing is fast becoming a mainstream technology. It is also one of the rapidly evolving technologies around the globe. So, before you set foot into the 3D printing realm, keeping these six pointers in mind will help you make the right choices. There are of course many factors, but hopefully these give some starting points to think about.

Have you bought a 3D printer before? What things did you consider while buying it? Do tell us in the comments section below.