French sports car manufacturer Bugatti first made its mark on the world with the Bugatti Type 35 race car (“the Bugatti Baby”) in the early 20th century.

While the Bugatti family may have passed on and its name may now belong to the Volkswagen Group, the Bugatti Type 35 has been reborn as the Bugatti Baby II.

At €30,000 a pop, the Bugatti Baby II is a limited-run electric vehicle for kids of an advantaged socioeconomic status. When actually manufactured, the vehicle will be three-quarters of the size of the original Bugatti Baby and will include a 3D-printed frame.

Other features include a rear-wheel-drive powertrain that runs off of removable lithium-ion batteries. The vehicle will top out at 12 mph in “child mode” and 28 mph in “adult mode.” An optional “Speed Key” will allow users to disengage the speed limiter and access all 10kW of the vehicle’s battery.

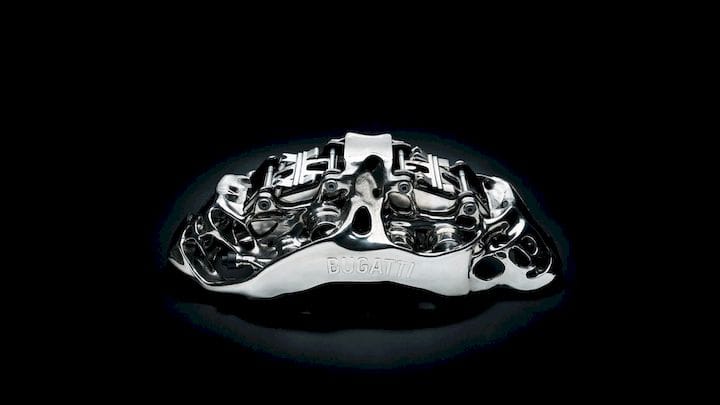

Though the kid car pays tribute to Bugatti’s legacy, the 3D-printed frame recalls more recent developments within the business. Bugatti has already been working with metal 3D printing company SLM Solutions since 2014, using the technology to 3D print a brake caliper that is said to be the largest functional part 3Dprinted in titanium.

Read more at ENGINEERING.com

Healthcare 3D printing attempts to solve two problems that plague providing care: customization and cost.