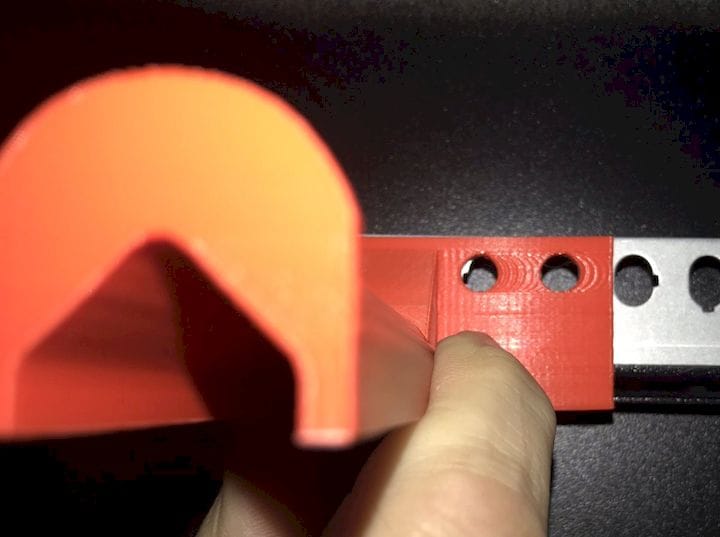

![Installing custom 3D printed fixtures [Source: Glen Beer]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a10bdecaa.jpg)

I happened to bump into a new 3D printing application during a data center tour, and this could be big.

The data center in question was an internet exchange, a place where multiple internet service providers establish a presence for purposes of quickly interconnecting with other regional service providers.

The reason for this type of facility is that without them internet traffic between two adjacent stations might have to traverse thousands of kilometers, perhaps even international borders, just to get across the street. That is, unless you have a local or regional internet exchange to quickly form a local bridge to avoid long network paths.

There are many such operations worldwide; I just happened to be visiting one of them. But what I saw was quite interesting when it comes to 3D printing.

You would not expect 3D printing to be used at all in a data center; they are typically a closed environment holding a variety of networking and computing equipment, and occasionally a chilled technician.

But this data center had plenty of 3D printing taking place.

![A typical data center cabling scenario: how do you keep track of and maintain all the connections? [Source: Glen Beer]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a10c4e4a7.jpg)

The nature of an internet exchange’s business is that the participating service providers are always expanding their capacity at the site or swapping out older equipment for more powerful new equipment. The data center is a hive of installation, deinstallation and upgrade activity. Each job tends to bring in different forms of equipment and cabling.

The problem facing the exchange is thus how to manage all the varied cabling and equipment constantly appearing. As you can see in the above image, things can get quite complex. It is of critical importance to know where each and every cable travels, as well as being able to potentially remove them without disturbing other nearby cabling or equipment during upgrades.

Their answer was to custom-3D print jigs and fixtures to assist the installation and maintenance of cabling and equipment.

![3D printing custom data center fixtures [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/data-centre-printing_result_img_5eb0a10c9d545.jpg)

If a new installation requires, say, a swath of 24 new cables, they might print something like this to isolate each cable:

![A 3D printed cable isolator [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a10ce9830.jpg)

This provides a means for the organization to easily maintain a neat and tidy machine room. All it takes is the ability to quickly design the relatively simply structures needed as requirements arise, and the ability to print them.

In this case, the operation was using Tinkercad to design the necessary parts, which is somewhat surprising, as that tool is generally thought of as an introductory 3D design tool. But on the other hand, if Tinkercad can produce the simple structures needed, then why bother with more expensive and difficult-to-learn 3D CAD tools? And indeed, most of the geometries needed to handle this application are quite simple – no moving parts required.

![A custom-designed data center cable guide [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a10d44245.jpg)

We’re told this particular operation now has 18 3D printers on the job. This may sound like a lot, but with upgrades and installations happening almost daily, some of which may require dozens of cable holders, troughs, corner guides, etc, these machines can be busy.

We’re also told by representatives at the site that when discussing this with colleagues from other data centers, it appears that almost no one else is doing this. It may be that this is an untapped application for 3D printing.

While this particular organization is usually designing their own parts, it would seem to me that it might be useful to create a library of commonly used articles for this application. Or perhaps even devise some type of generative system to pump out a “37 cable holder”, for example, where the design is driven by the specific need.

I suspect this is a very common application that any data center could potentially take advantage of. How many data centers are in your city? Probably dozens, all of which will need to handle equipment installations and upgrades. This is a market that I don’t feel has been properly addressed by 3D printer manufacturers, who seem more interested in servicing manufacturing. But this could be an interesting area of exploitation for a crafty 3D printing company.

My suspicion is that there are many other hidden applications of 3D printing just waiting to be exploited. All it takes is a curious mind and the recognition that a solution is at hand.

Healthcare 3D printing attempts to solve two problems that plague providing care: customization and cost.