![Advanced methods of using fiber to strengthen parts [Source: University of Surrey]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a54506dbc.jpg)

A paper from the University of Surrey details a new materials concept, but perhaps this could be done with advanced 3D printers.

Their idea is an innovative approach for integrating strong fibers into material. Yes, this has been done before countless times in order to make materials far stronger: carbon fiber sheets are precisely this.

The strength results from the fact that the fibers are much stronger than the surrounding material, which is usually a solidified resin. Making a strong sheet is typically accomplished by wrapping a mesh of woven fiber around a mold and covering it with a resin. These strong parts, usually of carbon fiber, are both light and expensive.

The strength of these parts is far more than can be accomplished with standard 3D printers. Therefore a very few 3D printer manufacturers have endeavored to integrated carbon fiber into their printing processes. I’m not talking about the relatively common “carbon fiber filaments”, which are simply a standard filament mixed with a great deal of chopped fibers. Once the fibers are chopped, their true strength advantage evaporates. Instead, I’m talking about continuous carbon fibers.

Markforged delivers a unique 3D printer that literally lays a continuous strand of carbon fiber down in mid-print to add significant strength to their nylon prints. Stratasys has also been experimenting with a similar approach with their robotic demonstrators.

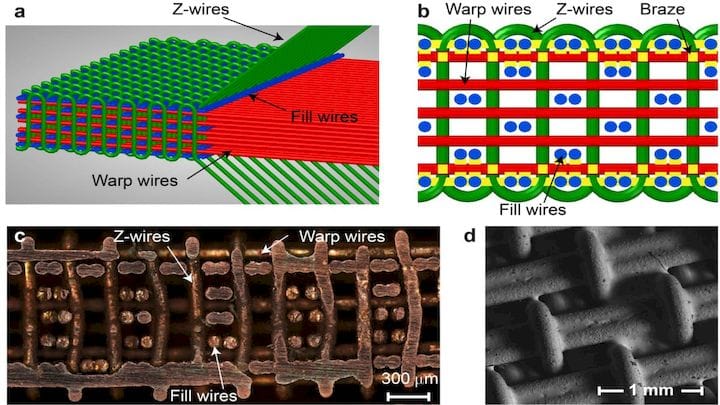

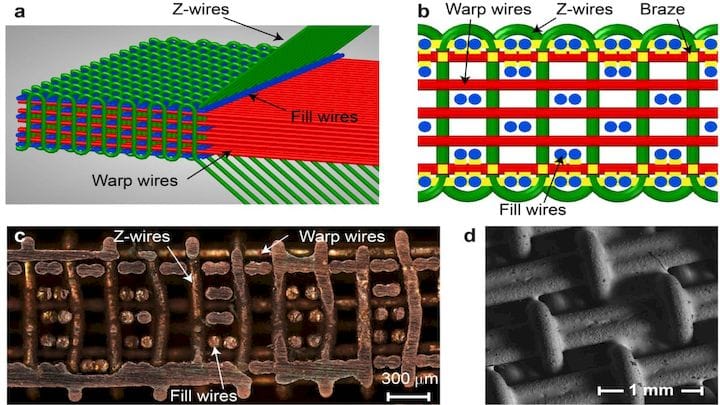

Meanwhile, the researchers from the University of Surrey, Johns Hopkins and UC Irvine have realized that if one could directly manipulate the fiber strands in length, position and orientation objects with extraordinary properties could be created.

Imagine a long part, where there are, say, carbon fibers running continuously from end to end. This part would be considered quite strong. But now imagine if those fibers were synchronously separated at a position in the middle of the long piece. Now you have a part with two very strong segments and a not as strong central section, perhaps to add the ability to bend, absorb shock, or even fold.

That is a very powerful concept. They explain:

“The team achieved this near impossible combination in a material by using 3D woven technical textile composite sheets, with selected unbonded fibres – allowing the inside of the material to move and absorb vibrations, while the surrounding material remains rigid.”

That’s quite amazing, but now I am wondering whether this could be done by 3D printers.

If a 3D printer were equipped with an ability to insert continuous fiber this approach could be attempted, at least on non-woven fibers. I’m not sure if Markforged’s slicing software is able to do this, or whether their users are aware of this possibility.

There are further possibilities here: imagine a 3D printer that had a kind of sewing machine-like tool head instead of an “insert fiber and cut” tool head. Now you might be able to attempt far more complex fiber configurations.

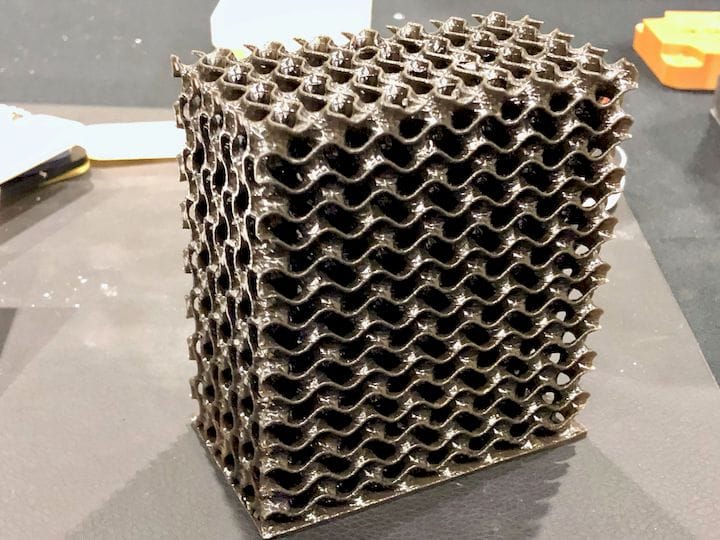

I view this as an inevitability, although it surely does not exist now. The reasoning is that traditional fiber methods invariably result in 2D surfaces curved in 3D, like automobile fenders. 3D objects are nearly impossible to produce using the traditional approaches and thus the ability to do so using 3D printers could open up an entirely new realm of fiber design.