![A 3D print using aligned cellulose nanofiber hydrogels [Source: Science Direct]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb094e83d9a1.jpg)

Researchers have developed an approach that could lead to true wood 3D printing material.

Presently when one says “3D printing in wood” it usually means that someone has mixed in fine wood powder (sawdust, essentially) with a polymer (usually PLA) to make a filament that is part wood and part polymer. This filament is then printed in the usual FFF manner, resulting in a somewhat wood-like 3D print.

These prints can be sawn, painted, sanded and used in a manner quite similar to actual wood, but they aren’t really wood. They’re also quite a bit heavier than real wood.

This is because actual wood has a highly complex microscopic structure made from dead tree cells that have been carefully aligned and joined together. This is all done by nature through genetic means, and results in wood, a fantastic material that is not only strong, but also quite lightweight.

The problem with wood is that it cannot be shaped in all possible geometries. It must be subjected to subtractive manufacturing processes and we all know their limitations.

If only actual wood could be 3D printed, these limitations would be overcome.

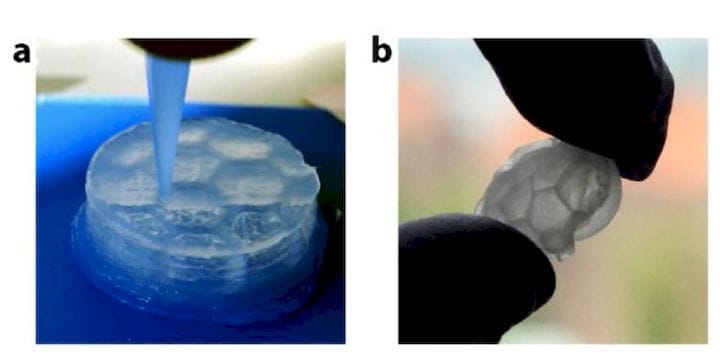

That’s the goal of the researchers from Chalmers University of Technology in Sweden. Their idea was to leverage previously made cellulose nanofiber hydrogels to attempt a new type of 3D printing approach.

Essentially the strength of wood is derived from the alignment of fibers within the structure. The researchers developed a way to approximate this geometry by re-aligning the extruder and print during printing operations.

They were able to somewhat control the fiber alignment by, say, rotating the print bed, allowing the extruder to deposit material with a different internal fiber angle. By controlling these movements carefully, they were able to print small objects with wood-like strength characteristics.

Of course, actual wood will have truly microscopic fiber structures, and a typical 3D printer extruder is a monstrously larger device. You cannot 3D print microscopic structures with a fat 0.4mm nozzle as hard as you might try.

Nevertheless, their experiments showed some effect on the strength of the prints with the cellulose material. This could lead to some interesting possibilities.

Imagine — and I think the researchers might be contemplating the same idea — if you could scale down drastically the size of the deposition nozzle to microscopic sizes. Then if this process were repeated, it may actually produce true wood prints.

Or at least a substance that has many properties of real wood — and can take advantage of 3D printing properties, such as complex geometry, custom 3D designs, and much more.

However, doing so likely requires development of a new 3D print nozzle and mechanism. Even worse, such a printer would likely take a very long time to deposit material sufficient to form even a small object: imagine 3D printing an object with layer sizes of 0.00001mm. Perhaps this could be overcome by performing parallel deposition: could inkjet arrays be used for this in some way?

Regardless of the practicalities, this is surely an interesting development.

Via Science Direct

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.