Our test of the new Anycubic D2 DLP 3D printer continues with a look at operations and software.

This is part two of a three part series, please read parts one and three.

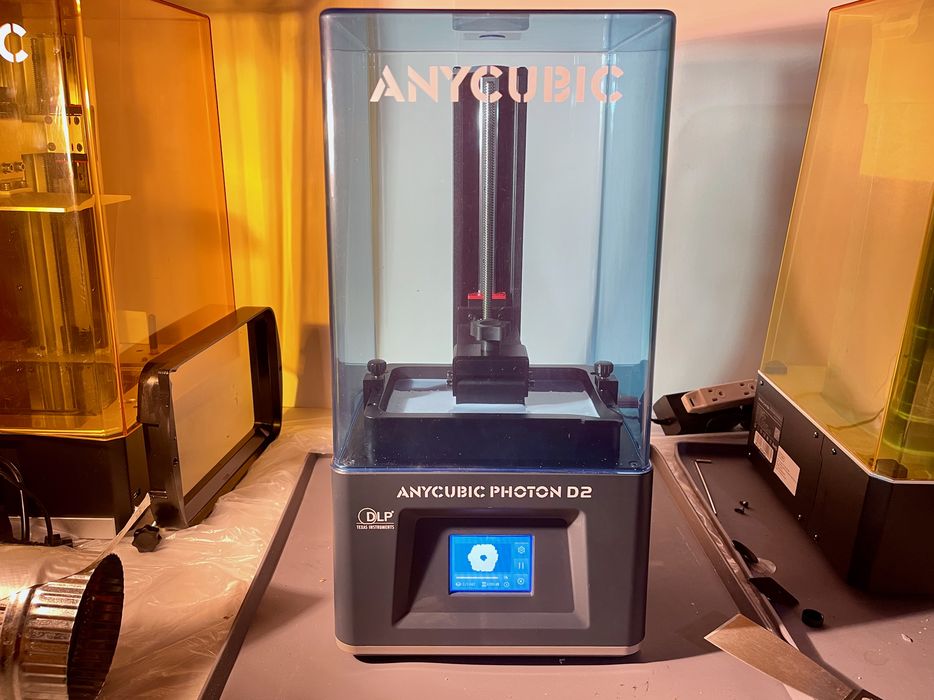

Anycubic D2 DLP 3D Printer Operations

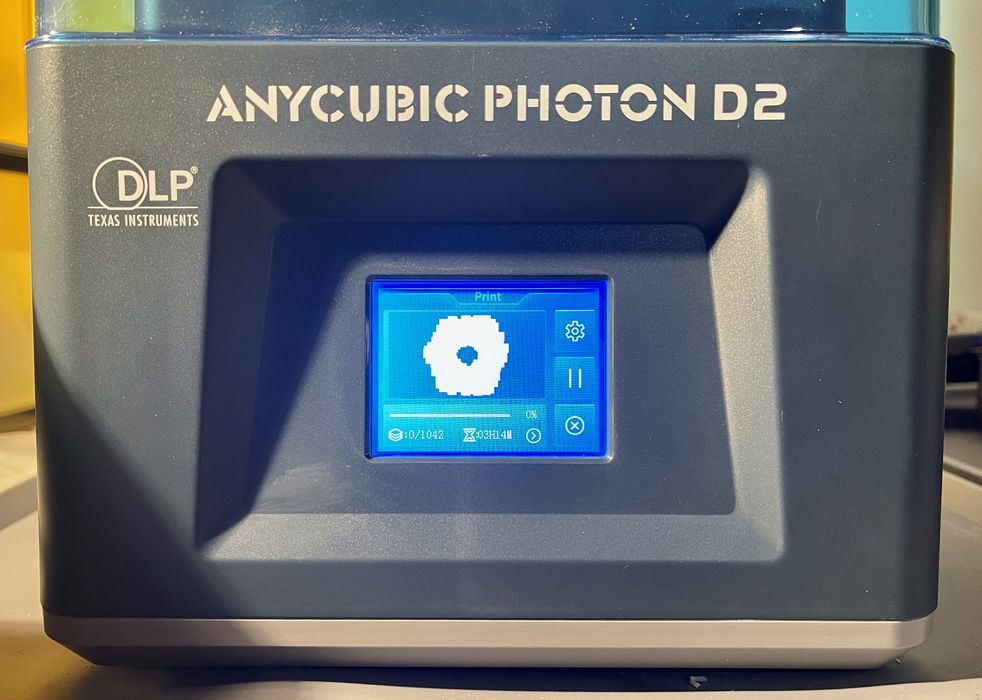

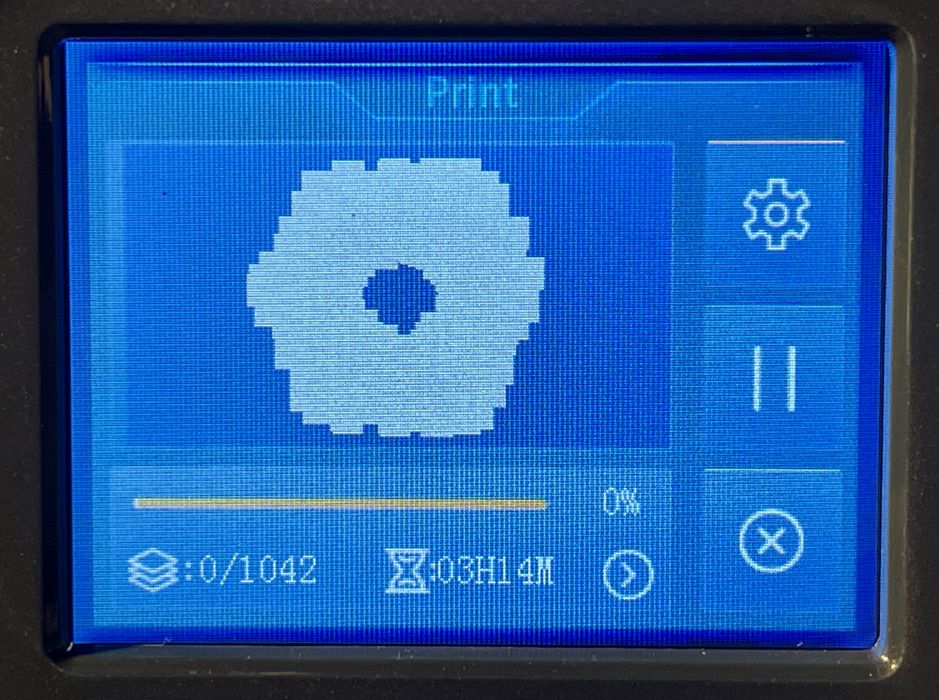

Operations of the D2 is mainly done through its touch screen.

A word about this screen: it is pretty small, but that’s mostly a product of the D2’s overall small size. However, I did find the screen very sensitive, and my fat fingers often hit the wrong button. Basically, my advice is to be very precise and careful when hitting these buttons, or you will find yourself powering off the machine before it does something you didn’t want.

The user interface is pretty easy to follow, as there aren’t that many things to do on a resin 3D printer. One thing to do is become familiar with the process to rise up the build plate, because you will often want to do that when removing a completed print. This requires you to set the amount of movement AND hitting the “up” button.

Physically, there’s not much to the machine. The blue cover lifts off, and I should note that this machine does not have a detection mechanism for the cover’s presence. You could lift the lid off during printing, but don’t do that!

The power switch is on the right-hand side of the machine, alongside the USB-A port where you insert a stick containing GCODE for printing.

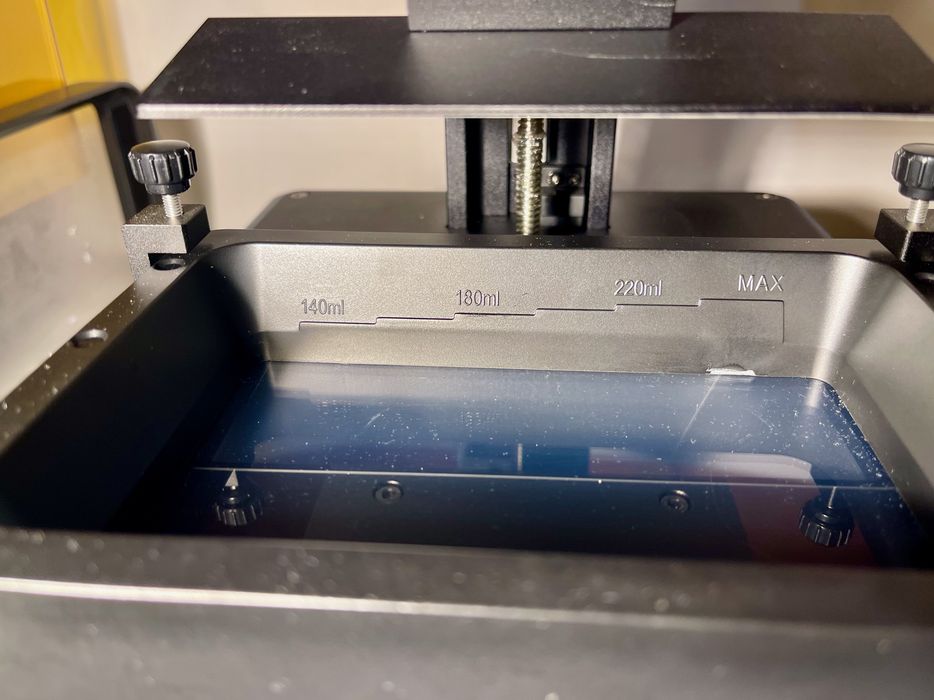

Finally, the small resin vat includes markers on the sides (both sides, it’s reversible), so you can tell exactly how much resin is in the vat. This is a feature Anycubic frequently uses on their vats.

You may notice that the vat seems quite “deep”, but that’s an optical illusion. The small size of the D2 clashes with the standard height of the vat, making it look taller than it really is.

Anycubic D2 DLP 3D Printer Software

The software to be used with the D2 is Anycubic PhotonWorkshop, the main utility provided by the company for use with all their resin equipment. It’s available for Windows and Mac OS.

It’s fairly easy to use, if you know the quirks in the system. It’s able to generate “dl2p” files required by the D2.

Anycubic PhotonWorkshop is able to handle multiple files in the same job, although all must use the same print parameters. There are plenty of settings available, but the primary setting is that of resin exposure time, which is used for calibrating the resin.

I successfully 3D printed a number of items on the D2 using Anycubic PhotonWorkshop, but I do have two comments.

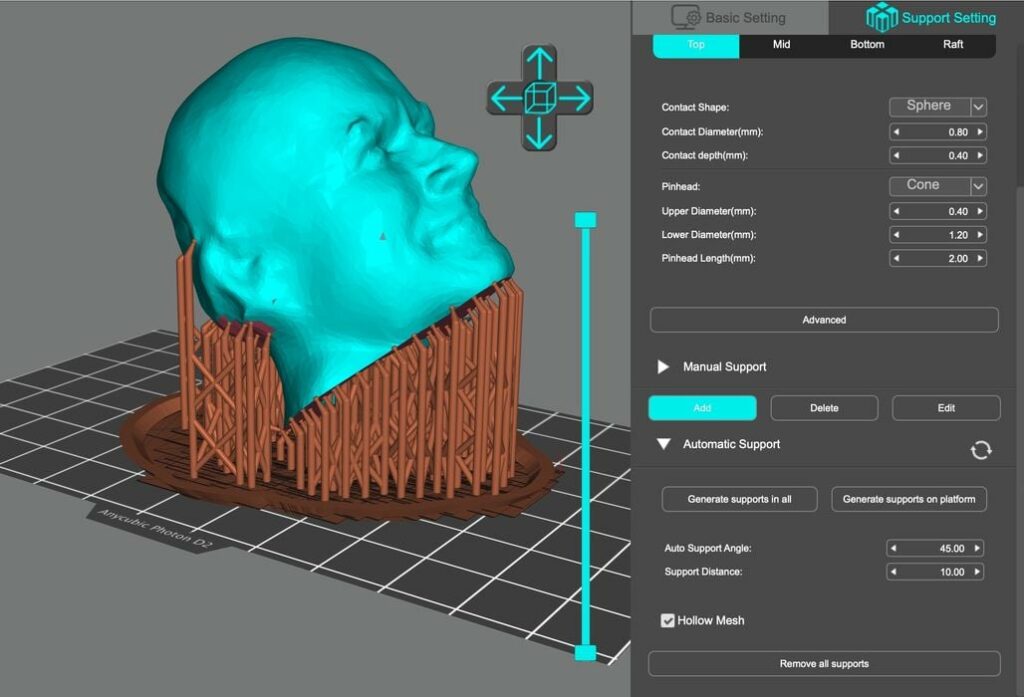

First, I don’t like the automatic support generation feature on the software. The idea is that it can generate all the supports required for a given object, but I found the software would rarely generate proper supports for me. Almost every job required manual intervention to add supports or fix the generated supports.

Here is a typical result of poor support structures: the print fell off during printing. If the support structures were properly generated, then fails like this would not happen and time & resin would not be wasted.

There were cases where NO supports were actually generated, but that’s very obvious and no one would proceed if they saw this.

My recommendation is to try to use the PhotonWorkshop supports as a starting point, and then add/subtract as necessary manually to get a configuration that works.

I did notice a number of quirky bugs in Anycubic PhotonWorkshop that I should mention. None are critical, but it helps to know they are there so you can work around them.

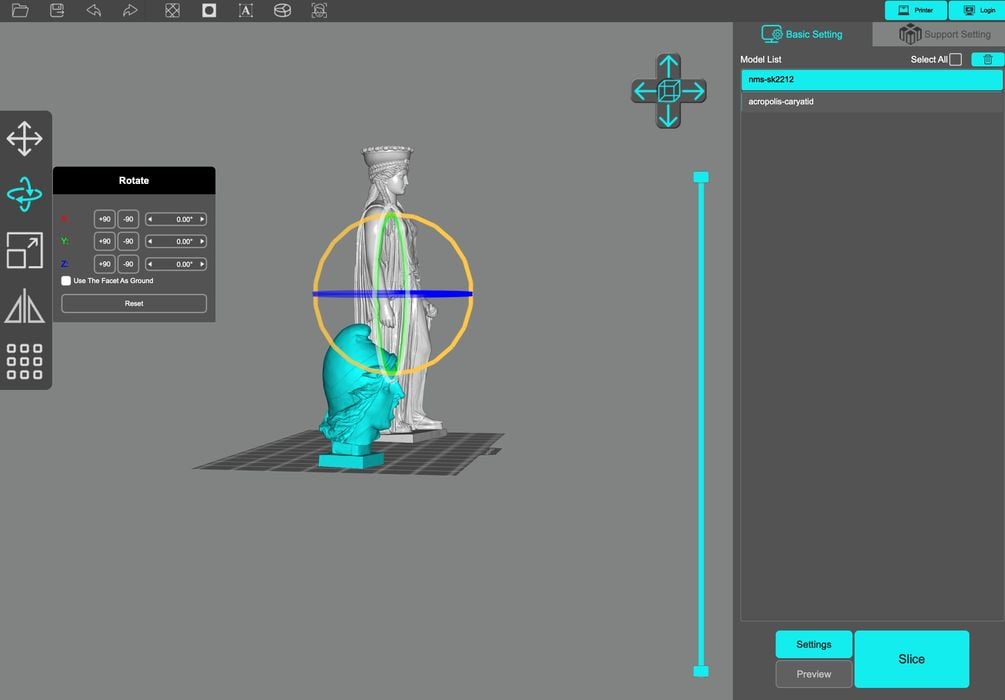

One was that when adding objects that are resized, the previously added objects also get resized. Oops!

One annoying bug was that when rotating an object you must “turn the wheel” on the screen. However, if the wheel happens to lay on top of a view of another object, you don’t operate the wheel! Instead it selects the background object. The wheel should be top level in the software, but it apparently isn’t.

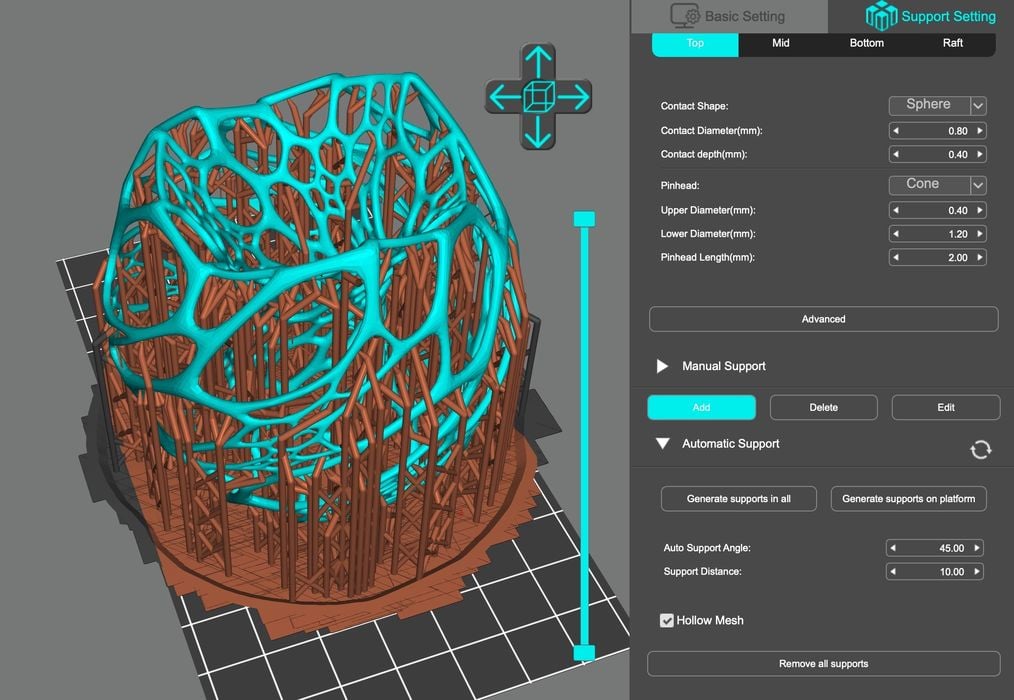

Another issue was that the raft size doesn’t seem to be observed by Anycubic PhotonWorkshop. Here I generated supports and a raft, but notice that the raft actually appears out of bounds. I had to resize / reorient the object to ensure the raft was entirely in the build volume. This could be detected automatically.

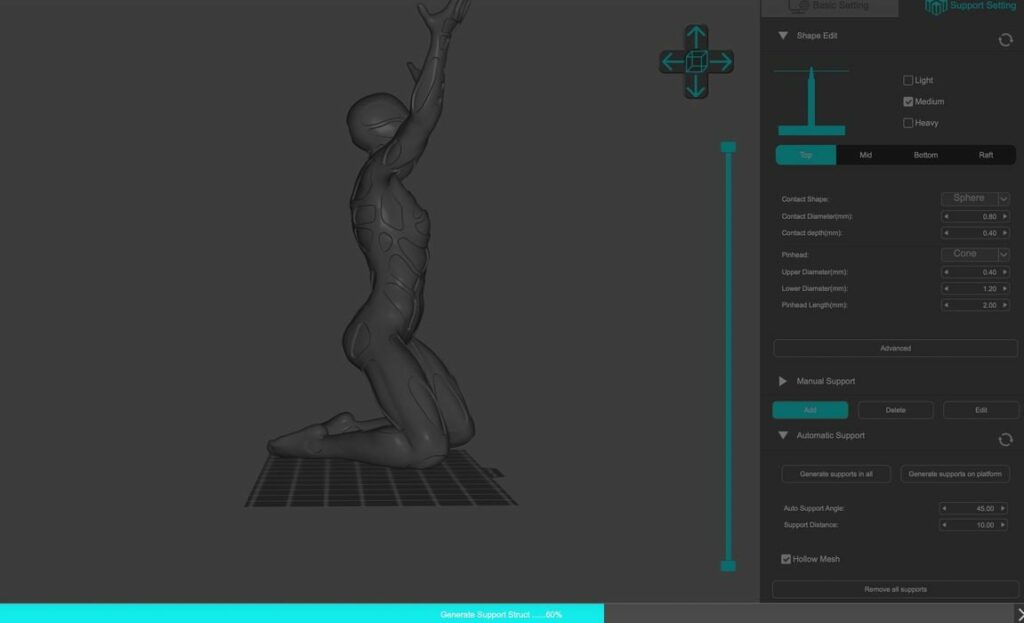

Finally, I actually had a case where the software got stuck and froze. I was attempting to print the Pencil Host 3D model, but in several attempts the software would stop around 60% through generating the support structures. In the end I just could not print this 3D model.

I did consider using alternate slicers, as I do have access to the popular Lychee Slicer, but I could not find a way to configure the D2 and make it work with that software. There doesn’t seem to be a way to use anything other than Anycubic PhotonWorkshop. I believe Anycubic should consider releasing D2 configurations for other slicing systems, as operators will want to use them from time to time.

[UPDATE] Anycubic informs us that yes, the D2 is supported only by PhotonWorkshop at this time, but they hope to release support for both Lychee and Chitubox slicers in about three months from now.

This is part two of a three part series, please read parts one and three.

Via Anycubic