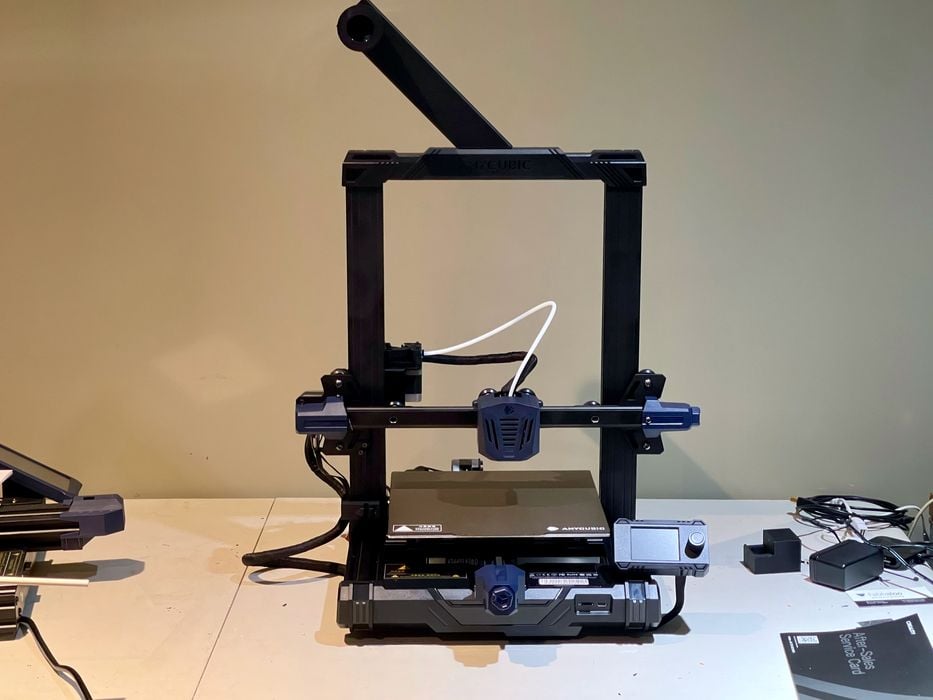

Our test of the Kobra Go desktop 3D printer concludes with a look at print quality and our final thoughts.

This is part three of a three part series, please read parts one and two.

Anycubic Kobra Go Print Results

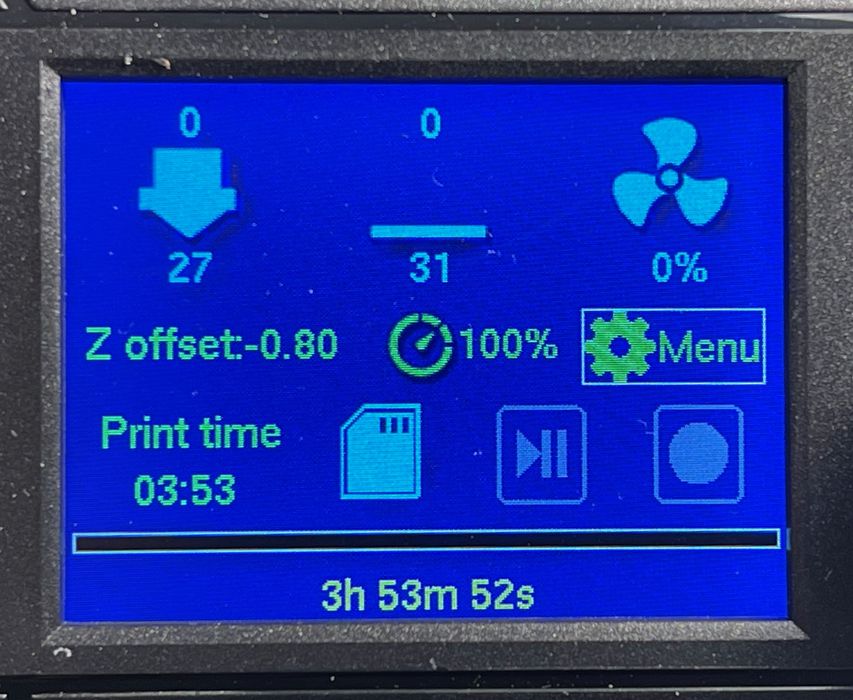

Before looking at the print results themselves, I do want to mention the print time estimates. I found these to be consistently off when comparing the slicer time estimate with the actual run time. Typically the actual times were about 20% longer than estimated, and that can be significant.

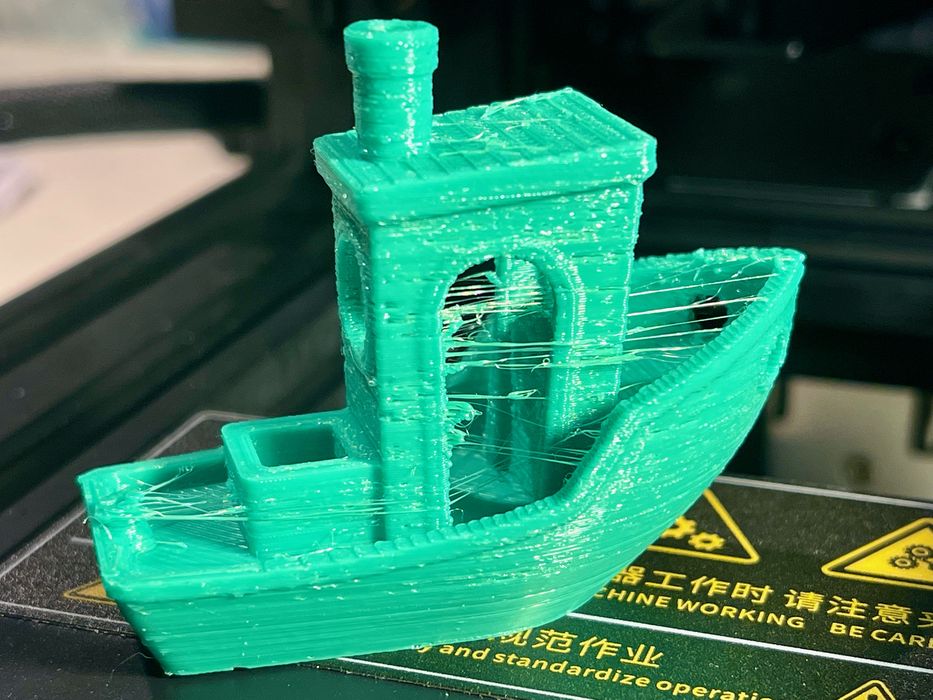

There’s a bit of a story about these print results that must be told. My initial prints used the Anycubic green PLA material, and the results were, I guess, “OK”?

The #3DBenchy you see above was printed with the supplied PLA profile. It’s got a lot of stringing, which isn’t unexpected for a Bowden machine, but there’s lots of gaps and blobs.

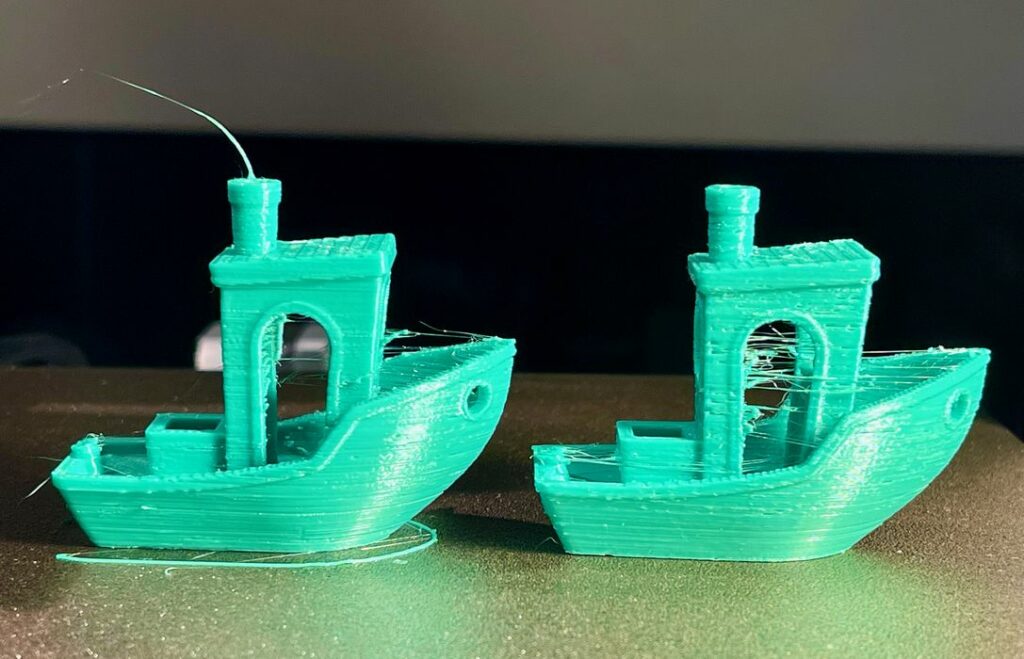

I thought I could do better, and did some tuning. Here’s a second, tuned #3DBenchy compared to the first one:

It’s a lot better, but still not quite right.

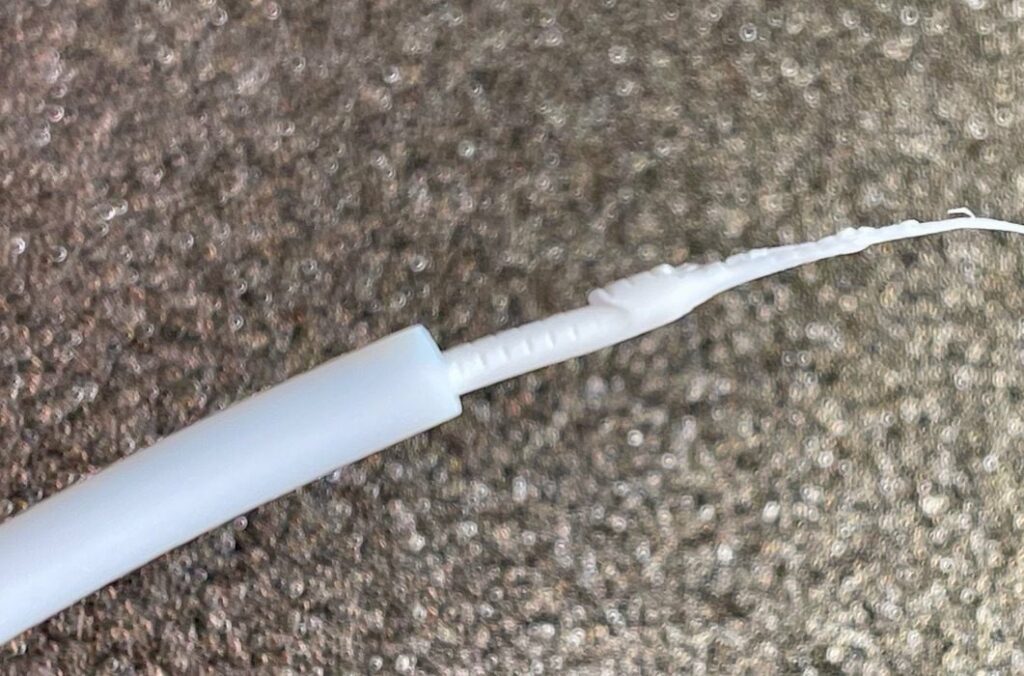

An aside here: during printing I found an operational issue. Anycubic provides a short PTFE tube to protect the filament from hitting the threaded rod, which makes sense.

However, the PTFE tube is not attached, and can easily come out. In fact, I often found it on the spool or floor after swapping filament, as seen above.

The reason for this is that the Kobra Go hot end tends to form larger blobs on the end of the filament. Thus, whenever you remove filament, you are guaranteed to remove the PTFE tube at the same time. Anycubic should fix the PTFE tube somehow.

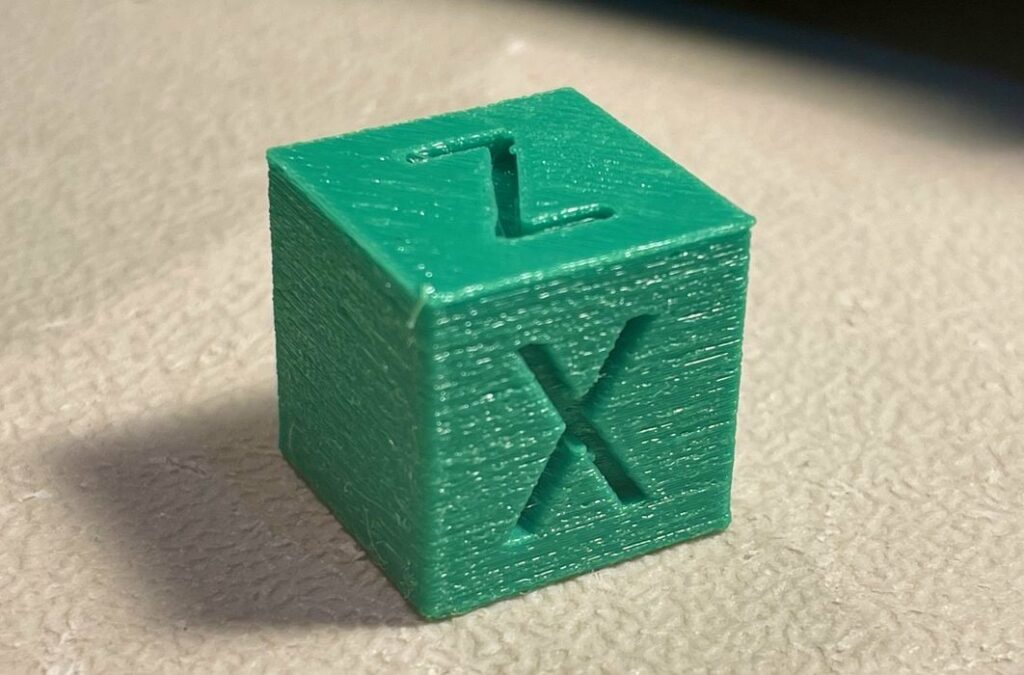

kobra-go-green-xyz – 1

I then printed the XYZ calibration cube. It also exhibited some strange surface textures.

A nut and blot came out sized perfectly and fit together well. However, there was a noticeable seam on one side.

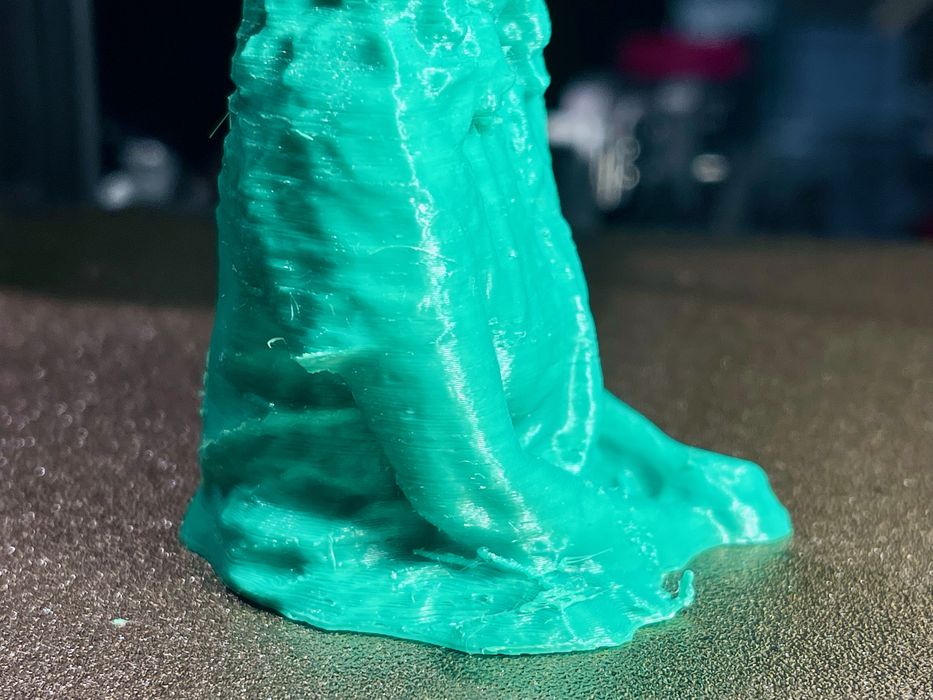

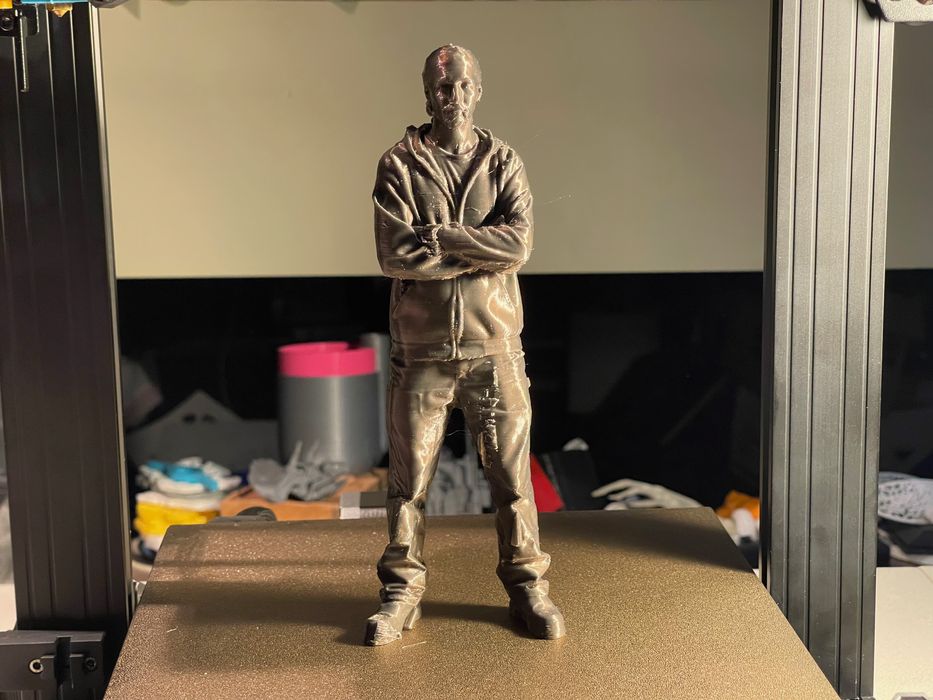

I printed a sculpture and found that it came out with a ton of stringing and again more weird surface texture artifacts.

After cleaning off the crap, it wasn’t too bad.

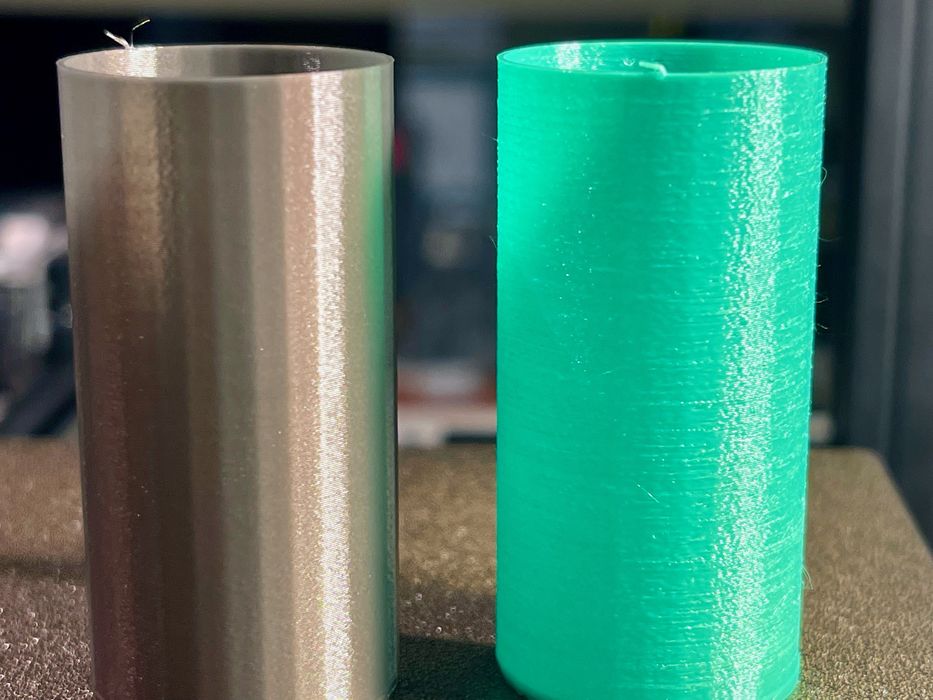

This surface texture problem nagged at me, so I decided to swap filaments. Instead of the supplied Anycubic filament, I used some fresh Prusament, a very high quality filament.

I printed a couple of cylinders in both materials to compare results, which were astounding.

Evidently the Kobra Go is very sensitive to filament quality for some reason. You can see the Prusament being laid down perfectly in this print. Either that, or the Anycubic filament was from a bad batch.

Here I 3D printed MakerBot’s cylindrical calibration test, and it was literally perfect in every way. These parts even fit together perfectly, which does not happen often on inexpensive 3D printers.

A tall 220mm print came out very well (the blobs visible are from support junctions after removal, not indicative of print quality).

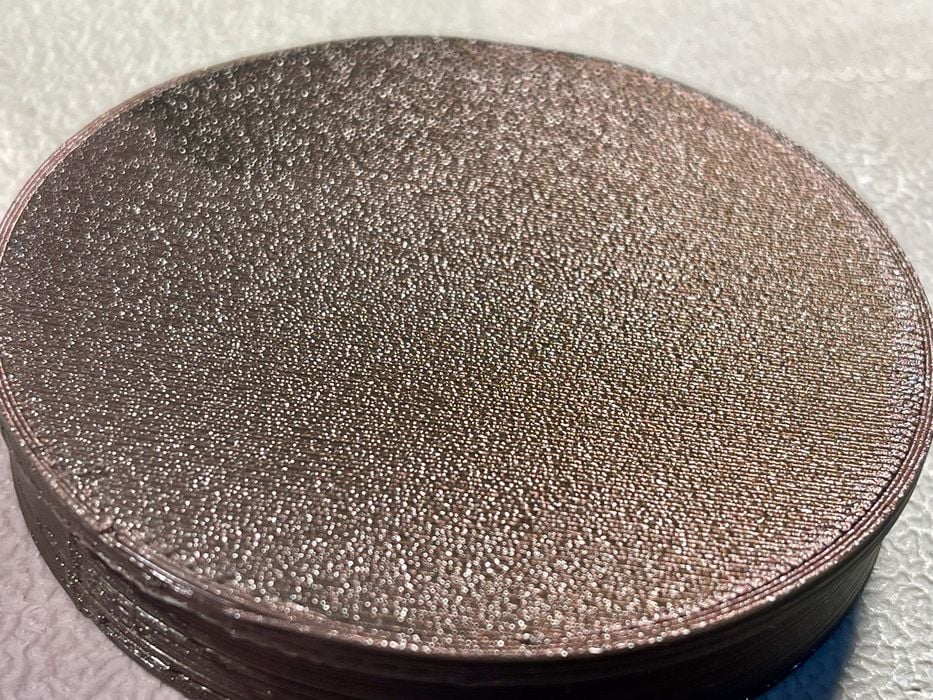

I found the bottom of each print to have a very nice texture, courtesy of the removable magnetic print plate.

Moving on to ABS material, I found the Kobra Go could indeed print with ABS right off the hop. However, I did notice some weird brown bits that might have been residual PLA that cooked at the higher temperatures.

Even an ABS #3DBenchy came out pretty well. I thought this was an admirable result for an open-air US$189 machine. It’s very likely you can print some smaller mechanical parts in ABS on this device.

Although the documentation for the Kobra Go does say it supports TPU and a profile was provided, I didn’t bother testing that material. There is no way my floppy TPU would ever make its way up the Bowden tube without jamming. I suspect if you had some somewhat stiff TPU it just might work, but I didn’t have any on hand.

Finally, I want to comment on the the Kobra Go’s print plate, which I have to say is one of the most effective I’ve ever used. Somehow it keeps prints tight to the plate, but at the same time the prints are almost always loose when it cools down. Watch this video of me picking up a large print, and this was not staged, it’s right after the print completed:

Just a satisfying “click”. No need for chisels and wrestling to remove these prints. Amazing!

Anycubic Kobra Go Final Thoughts

After using the Kobra Go for a couple of weeks I am very impressed. This is the most inexpensive machine I’ve yet tested, and even so it produces extraordinarily good prints, assuming you provide it with high quality filament.

While there is some effort required to assemble the machine, it is an easy process that almost anyone could complete successfully. Anycubic could improve their instructions even more with some clarity here and there, and better yet it should be online where users can add tips in comments. Overall the assembly process did add quite a bit to the experience.

This is an ideal machine for those with an interest in building a machine themselves. This machine is far better than its price suggests, and performs better than many more expensive machines.

ANYCUBIC

KOBRA GO 3D PRINTER

★ BEGINNER 9/10

★ ENTHUSIAST 9/10

★ PRODUCTION 6/10

BEST FEATURES

✔︎ Low cost

✔︎ High quality prints

✔︎ Incredible print plate

QUESTIONS

✖︎ Spelling errors

✖︎ Loose PTFE tube

✖︎ Dynamic Z-offset

This is part three of a three part series, please read parts one and two.

Via Anycubic

Velice pěkný a poučný článek k této tiskárně. Děkuji