![Slicing a 3D model in ChiTuBox [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0953c1bb1b.jpg)

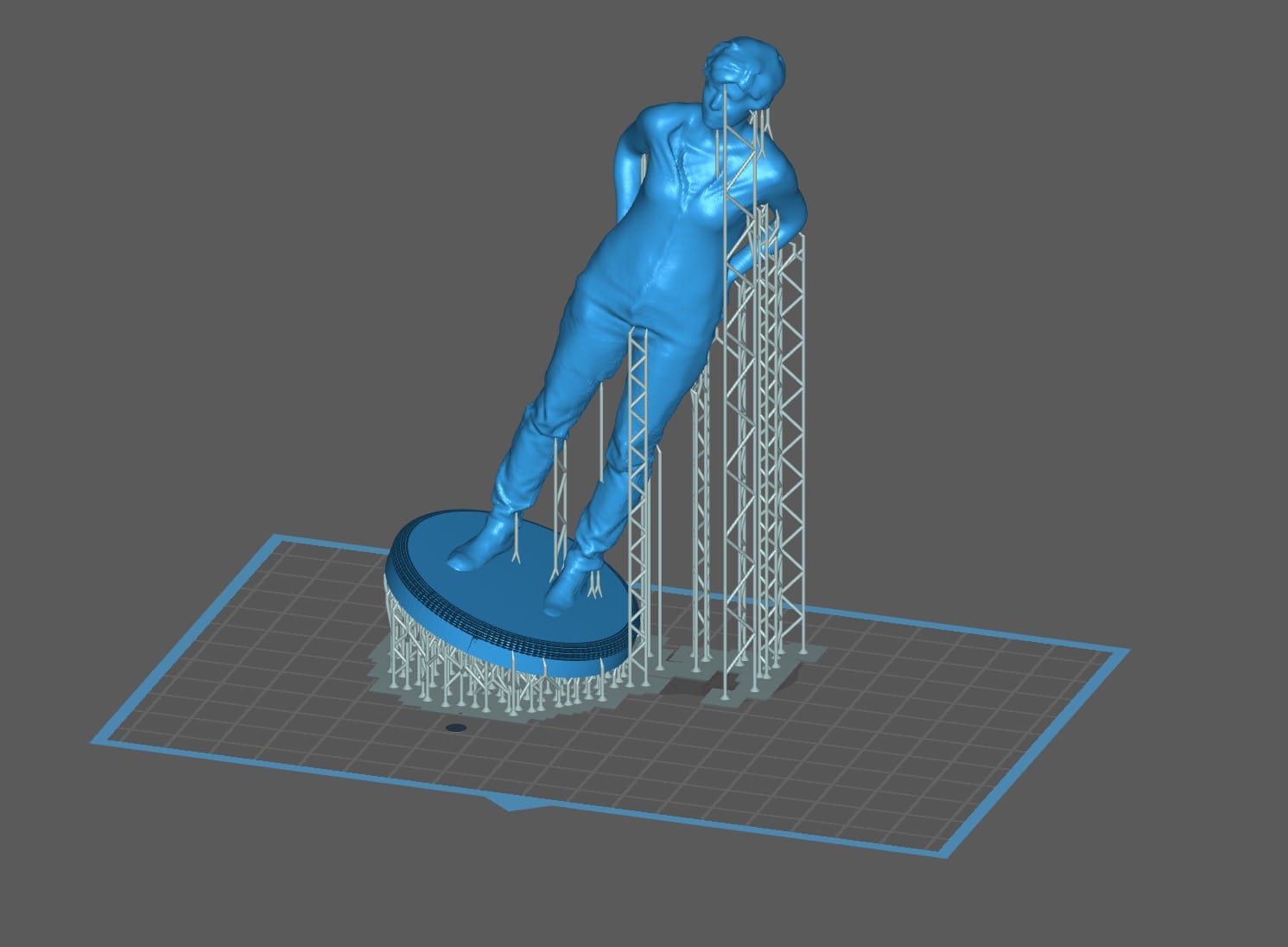

I’m taking a look at ChiTuBox, a third party 3D print slicing system.

If you were to ask a 3D printer operator to name a list of slicing systems, they would probably name Cura, Simplify3D, Slic3r and a few systems dedicated to particular machines. But there’s one thing all of these have in common: they are designed for filament extrusion systems, sometimes known as “FFF” for Fused Filament Fabrication.

That’s fine if you have an FFF-style 3D printer, but what if you don’t? What if you have one of the increasingly found desktop resin-style 3D printers? The machines that use a light engine and a photopolymer resin to produce objects in a completely different way?

Like FFF systems, SLA 3D printer manufacturers always bundle a slicing system with their equipment, otherwise the customers would not be able to do very much. Typically in the resin world the manufacturers tend to build their own slicing software. I suspect the reason for this is that many desktop resin systems have a business model that is based on proprietary materials.

These companies design machines that require the use of their own materials, which they produce at modest cost, but mark up considerably. This is how they make most of their money. For their traditional clients, this is not a big deal as it’s just a cost of doing dental / jewelry or similar business operations. The costs are simply passed on to their customers.

However, in recent years there has been a new type of SLA machine emerge: the low-cost hobbyist style of device. In many ways the business model for these machines echoes that of low-cost FFF machines: an emphasis on revenue from machine sales, and use of open materials.

But the “usual” third party slicing systems used by low-cost FFF machines don’t work for resin systems. Instead there’s a new space where slicing software can be developed. This is where systems like ChiTuBox come in.

Free 3D Print Slicer

It’s a free utility that is specifically designed to slice 3D models for use in SLA systems with resin machines using SLA/laser, LCD or DLP light engines. It provides a number of features that will be quite familiar to FFF 3D printer operators, including 3D model positioning, scaling, rotation, project saving, etc., but does so in an SLA environment.

One important feature is “hollowing”, where a 3D model is automatically hollowed. This allows you to print a “solid” object with far less material, as it can drain out during printing through a hole — which is also generated.

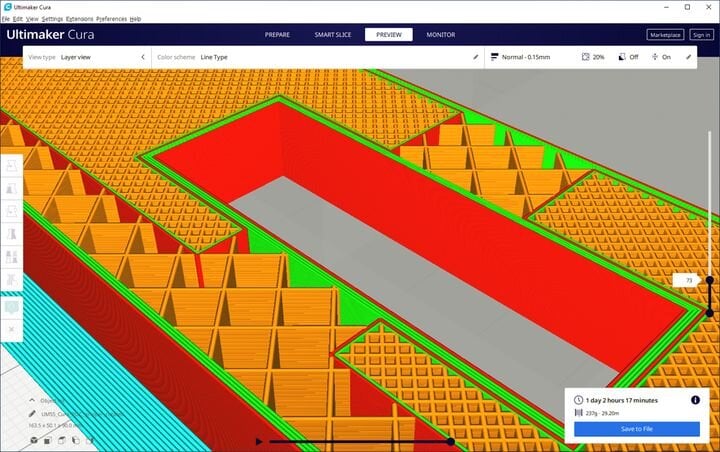

ChiTuBox Support Generation

![ChiTuBox’s support generation parameters [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0953c7f305.jpg)

An important aspect of SLA 3D printing is generation of support material, which ChiTuBox does. The system has considerable knobs one can turn to develop the optimum support configuration for a given 3D model.

At this time ChiTuBox provides support for a number of popular low-cost SLA desktop 3D printers, including:

-

AnyCubic Photo

-

AnyCubic Photon-s

-

ELEGOO MARS

-

Phrozen Shuffle

-

Phrozen Shuffle XL

-

SparkMaker FHD

-

SparkMaker

-

WanHao D7

-

WanHao D8

-

WanHao GR 1

ChiTuBox Futures

I’m assuming the company will eventually add a number of additional machines to their supported list.

Currently ChiTuBox is at release level v1.4.0, and is provided free of charge for Windows(64), Mac and Linux platforms. However, they hint at a future “ChiTuBox Pro” version that might include more advanced features — and a price tag.

Via ChiTuBox

MiniFactory’s new software produces a very useful report for each 3D print that may be important for clients. We had a close look at one.