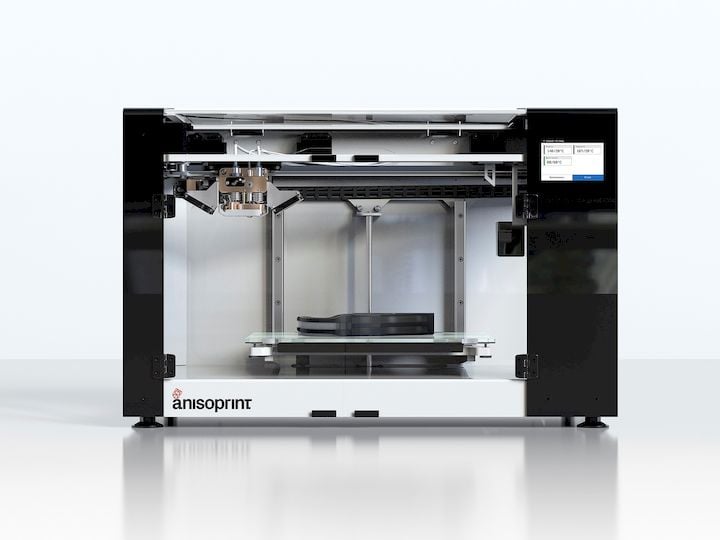

![The Anisoprint Composer continuous fiber 3D printer [Source: Anisoprint]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb095cb6b816.jpg)

Anisoprint announced a 3D print material I’ve never heard of previously, Composite Basalt Fiber.

The company is most well-known for their continuous carbon fiber 3D printer, able to insert continuous long strands of very strong carbon fiber into 3D prints. This is very different from most carbon fiber systems in which chopped carbon fiber segments are mixed in with a binder.

Yes, the chopped carbon fiber parts are somewhat stronger than just plain polymers, but if you can avoid the chopping — as Anisoprint does — the part takes on the strength of the embedded fibers.

This allows Anisoprint’s Composer 3D printer to produce very strong parts, sometimes as strong as or even stronger than metals such as aluminum or steel. But now they seem to have succeeded in solving another problem that arises when using continuous carbon fiber: price.

![The Composer 3D printer takes a spool of regular 3D printer filament as well as a spool of continuous fiber [Source: Anisoprint]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb095cbbc406.jpg)

As any 3D printer operator knows, the price of carbon fiber materials is significant, with the price rising as the carbon fiber ratio increases. A spool of pure continuous carbon fiber can be expensive.

ULTEM 3D Print Costs

Anisoprint analyzed a typical scenario in which they priced out the material costs required to produce a sheet metal mold for a helicopter component that must withstand 400 bar pressure. They used three different scenarios:

First, they used ULTEM, a well-known, strong, high-temperature material typically used in the aerospace industry. To achieve the necessary pressure capability, 100% infill of ULTEM was required on the test. The material cost was €300 (US$340).

The second test involved their own PETG+CCF combination, a PETG print with embedded composite carbon fiber. Due to the strength of the continuous carbon fiber, only 30% infill was required to achieve the pressure capability. The cost of this material was €150 (US$170), half the cost of ULTEM.

![Part 3D printed with continuous basalt fiber filament with the infill pattern [Source: Anisoprint]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb095cc0f0e3.jpg)

The final test involved their new material, PETG+CBF combination, involving continuous composite basalt fiber. This material combination again required only 30% infill, but the cost was substantially less at only €80 (US$90). That’s dramatically less than ULTEM, only 27% of the cost!

This is most certainly a price breakthrough and could allow companies wishing to produce very strong parts a huge cost break.

3D Print Electrical Properties

There’s another very intriguing property of the basalt material: It seems to be electrically transparent, unlike other high-strength materials. This is an often unreported property on 3D print materials, but it is critically important in some situations.

For example, one of our acquaintances was developing a case for a satellite phone. In such a device, the radio performance is the critical element and must be as operational as possible. Our contact found that there was often a difference between the available 3D print material and the final production material in electric terms. This significantly messed up their case testing.

Now with a material like CBF, prototypers could produce extremely strong parts with less concern for radio interference.

Anisoprint now sells 750m spools of CBF for use in their Composer 3D printer.

Via Anisoprint

There have been multiple attempts to develop continuously operating 3D printers, but none seem to have been widely adopted. Why is this the case?