![The Sliding-3D PLUS High-Temp Infinite 3D Printer [Source: Robotfactory]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0989e8fd4b.jpg)

Robotfactory announced a higher-temperature version of their infinite 3D printer.

The Sliding-3D device is a rarity in the industry, as it provides a practical way of printing objects infinitely. This is achieved through its use of a rolling belt as its print surface. Objects are printed at an angle as the belt slowly moves. When the completed object reaches the end of the belt, it peels off and falls into a bucket.

As long as you keep supplying the machine with filament, it will continue to print and fill your bucket with wonderful 3D prints. When we say “infinite”, we mean it. Another way to put this is that its build volume is 410mm x 380mm x infinity!

![The belt-printing concept on the Sliding-3D PLUS 3D printer [Source: Robotfactory]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0989f07c07.jpg)

Now the company has announced a tweaked version of the device they call the “PLUS”.

It is essentially the same machine, except that it has a hot end that can handle much higher temperatures. The Standard version tops out at 280C, but the new PLUS can hit 480C.

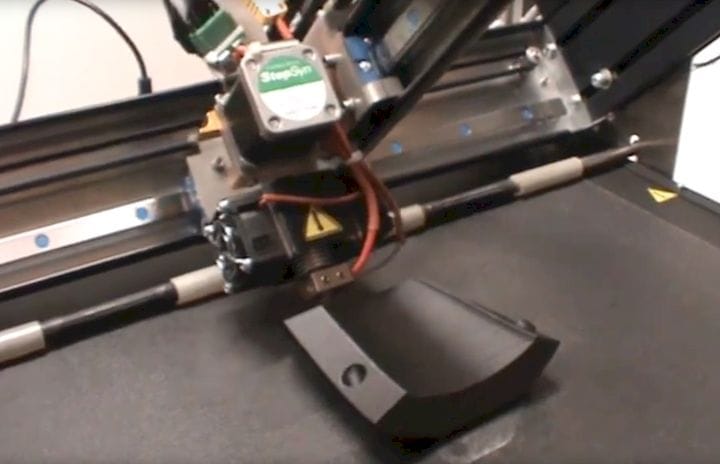

![The 480C-capable hot end on the Sliding-3D PLUS 3D printer [Source: Robotfactory]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0989f58cb4.jpg)

This means that the PLUS can theoretically print higher-temperature materials. Robotfactory says the PLUS can handle: “Carbon Fiber, Glass Fiber, PPS, Therme, PEEK, Ultem, PLA, Nylon, PETG, HIPS, TPU and other.”

The print bed, or should we say belt, is also heated and can be as high as 130C. This high temperature will also be very helpful when printing high-temperature materials.

They published a video of the PLUS printing an object in PPS-CF material:

This device is very interesting, but there seem to be some missing features on this device. As every 3D printer operator knows, high-temperature materials can be very tricky to print. The problem arises in the massive temperature differential between the hot end and previously extruded material that has cooled to ambient levels.

The temperature difference frequently results in warping due to the thermal expansion characteristics of many high-temperature materials. If the warping is significant, the print could dislodge from the bed and cause a print failure.

All high-temperature 3D printers I am aware of attempt to overcome this phenomenon by increasing the temperature of the ambient air in the build chamber. This is done by enclosing the build chamber and heating it explicitly. In some cases the build chamber’s atmosphere can be as high as 100C. This tends to minimize the thermal difference and reduce warping effects.

In its standard configuration the PLUS, like the original version, does not include an enclosure. Thus it is impossible to overcome the thermal gradient between hot end and ambient air, and considerable warping is therefore possible. Robotfactory does offer a “Protective Box” made from polycarbonate, but this seems far less robust than some of the purpose-built metal enclosures of other high-temperature 3D printers.

It’s also possible that buyers of the PLUS might be able to overcome warping effects by simply placing the PLUS into a heated chamber of their own design. However, this means that the device’s delicate electronics and motion system will be unexpectedly heated. This could cause damage to the device either immediately or over a longer period.

Another aspect I am concerned about is the viability of the belt material itself. If repeatedly exposed to extremely high temperatures up to 480C, is there a danger of it being softened and distorted itself? I don’t know what the belt is made of but in order to survive high temperatures, it must he made of something very temperature resistant. Robot factory says it is made of new materials, but we’re not sure exactly what they are.

Warping tends to occur more frequently when objects are large, and so it may be possible to successfully 3D print smaller objects on the PLUS. It could be that the PLUS might be an ideal machine for printing larger quantities of smaller sized objects in high-temperature materials.

Via Robotfactory

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.