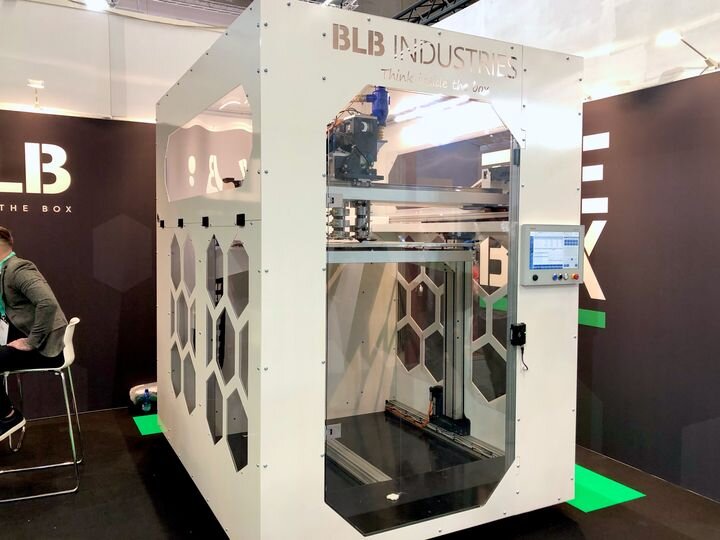

![TheBox, a huge large-format 3D printer from BLB Industries [Source Fabbaloo]:](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb050923af63.jpg)

One of the more profitable niches within 3D printing these days is the large-format business.

There are several companies pursuing this market, which enables manufacturers to produce huge prototypes, much larger than can be made on typical desktop equipment. In many industries this is a considerable advantage because the cost of producing traditional prototypes at huge sizes also carries huge costs and delays. By enabling the ability to 3D print a prototype in a few days things can change dramatically.

One new option we’ve recently seen in this space is Sweden-based BLB Industries AB. Founded relatively recently in 2015, the company now produces no less than three models of large format 3D printers.

Their 3D printer line has the ominous name, “The Box”, which comes in three different build volumes. Well, technically there are four as the company also offers the ability to build-to-order a version with a custom-sized build volume.

The defined versions of the Box have build volumes of:

-

1500 x 1000 x 1000 mm

-

1500 x 1500 x 1500 mm

-

2000 x 2000 x 1500 mm

You can see these are quite large machines.

All machines are certified to 3D print these materials, some of which are a bit unusual:

-

ABS

-

ABS with wood fiber

-

ABS with glass fiber

-

PP with glass fiber

-

PP with glass balls

-

Nylons

-

PE

-

PLA with wood fiber

-

PLA with copper powder

-

TPU

-

TPE

BLB Industries says many other thermoplastics are likely possible.

There are a couple of notable features on The Box that are specifically for large format 3D printing. One is that the machine accepts pellets, rather than filament, as its input material. This is not only vastly less expensive than filament, but also allows for speedy 3D printing.

BLB Industries has devised a fast extrusion system to accept pellets that is able to deposit as much as an amazing 30kg per hour. Each machine optionally includes a second extruder, allowing for the possibility of 3D printing support material.

One of the reasons they can 3D print so fast is that they employ large diameter nozzles on their equipment. The small and medium devices can 3D print with nozzle sizes ranging from 1.0 to 8.0mm, while the large The Box can use an enormous 14mm nozzle, perhaps the largest I’ve heard of.

BLB Industries doesn’t explain much about their thermal controls, but we do know the machines offer an enclosed build volume to capture heat. It’s highly likely they have at least a heated build platform, if not explicit chamber heaters.

This is required for materials such as ABS that have a strong tendency to warp during 3D printing due to the thermal differential between the freshly printed material and previously extruded material. Since they have certified ABS, I have to assume they offer thermal controls.

If you’re looking at large format 3D printers, BLB Industries offers some interesting — and very large — options.

Via BLB Industries