Our Learning Series continues

Our Learning Series continues

This is an entry in our 3D Print Learning Series, focusing on 3D print processing.

For other current entries in this series, please search for our tag, “learning series”, here. Search often, as we will be adding more periodically.

3D Print Processing

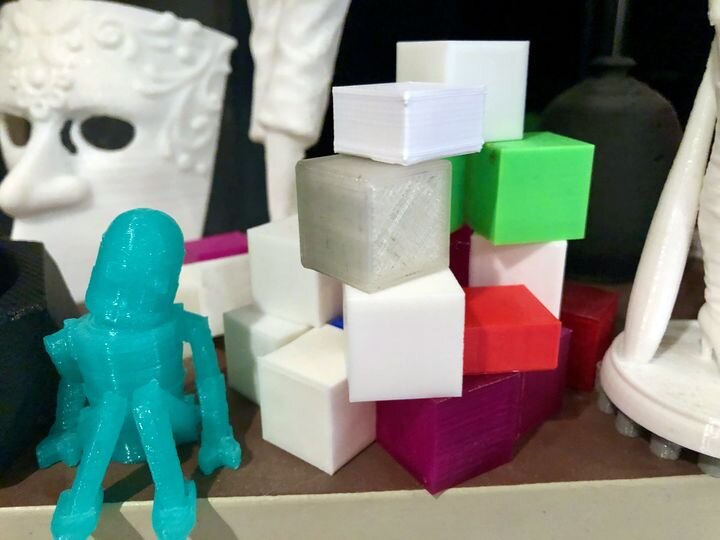

Those new to 3D printing often have the mistaken impression that once the print completes, you have a finished item. That’s almost always not the case, as there are multiple activities that commonly take place after the fact, including:

-

Support structure and raft removal

-

Stray material removal

-

Surface smoothing

-

Painting

-

Assembly of multiple parts

-

And more

The most obvious post-processing activity is the removal of support structures, which are usually quite visible. This often requires great care, as the support structures can be bonded with the model itself, and removal can accidentally rip off model material or even break the model.

Another much-discussed activity is the method of achieving smooth surfaces. Some recommend simply getting a better 3D printer (or adjusting an existing 3D printer) to have better resolution. However, the most effective, but perhaps most laborious, solution is post-processing in one of several ways to smooth the print surface.

But there’s more that can be done to “process” your 3D print than can be achieved after printing; a number of techniques during 3D printing can also help you meet your design goals.

Each heading below is a link to relevant processing information.

To Sand Or Not To Sand: An Experiment

![Methods of smoothing 3D print surfaces [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/to-sand_result_img_5eb099c6415a9.jpg)

The most obvious method of smoothing a 3D print is to sand the outside repeatedly, gradually decreasing the grit size. The extreme labor required for this has generated a number of other techniques, which are mentioned in this post. However, in the end a rather simple solution was discovered that you can use.

Some Resin Casting Tips When Using 3D Printed Molds

![Tips on casting 3D prints [Source: Eric Strebel]](https://fabbaloo.com/wp-content/uploads/2020/05/casting-tips_result_img_5eb099c6816a0.jpg)

One increasingly popular approach for finished 3D prints is to use them as samples for molding. In this way duplicates of a 3D print can be easily obtained. But exactly how do you design a 3D print so that it can more easily be used in a casting process?

3D Print Tip: Oh How I Love My Heat Gun

![My handy heat gun [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/heat-gun_result_img_5eb099c6c7564.jpg)

I use many different tools during 3D print post-processing, including pliers, snips, sandpaper and more, but one of my favorite and frequently used tools is a heat gun, which has some surprisingly practical uses.

Six Ways To Strengthen 3D Printed Parts

![A part that wasn’t strong enough [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/six-ways-to-strengthen_result_img_5eb099c7159c5.jpg)

If your 3D print is intended for use in a mechanical scenario, then it must meet target engineering properties, including strength. While one could simply accept the part as printed, there are some techniques for making a part stronger than it would be otherwise.

What Is “Neosanding” And Why Would You Use It?

![Normal print on the left, a “neosanded” part on the right [Source: Ultimaker]](https://fabbaloo.com/wp-content/uploads/2020/05/neosanding_result_img_5eb099c7664db.jpg)

Neosanding is a very unusual method of flattening horizontal surfaces on a 3D print. This particular geometry is frequently encountered on parts and generally looks like it was 3D printed as you can often see the extrusion lines quite visibly. However, neosanding, or “ironing”, is a radical method of making them less visible.

A Great Guide To 3D Print Post Processing

![From the 3D printer to completely finished [Source: 3D Hubs]](https://fabbaloo.com/wp-content/uploads/2020/05/postprocessingguide_result_img_5eb099c7a7ab5.jpg)

We found a very detailed guide to all the ins-and-outs of 3D print post-processing.

A Different Way To Color 3D Prints

![Adding color to a 3D print [Source: Formlabs]](https://fabbaloo.com/wp-content/uploads/2020/05/different-way-to-color_result_img_5eb099c7f0b28.jpg)

Formlabs devised a rather unusual method of adding spot color to finished 3D prints that is implementable on virtually any 3D printer using any material.

How To Smooth Your PLA 3D Prints

The quest to perform easy smoothing of 3D prints was partially achieved when someone invented the “acetone vapor” technique, in which a print is exposed to this substance, which causes the surface to slightly soften, eliminating layer lines. However, the chemical works only on styrene-based 3D print materials, such as ABS, ASA and a few others. What can you do to chemically smooth a PLA print?

How To Make Any 3D Printed Part Much Stronger

Another quest is to make parts stronger. Here we describe an unusual technique that is performed during the 3D printing process, and could be used in a variety of ways.

For other currently entries in this series, please search for our tag, “learning series”, here. Search often, as we will be adding more periodically.

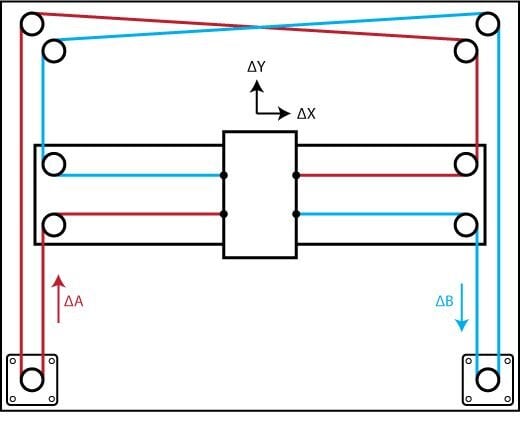

CoreXY is becoming a very popular approach for 3D printer motion systems, but is it the ultimate answer? We list the advantages and disadvantages.

VSHAPER has released a pair of interesting 3D printing guides, and unlike most beginner guides, these are designed for engineers.

I’m not sure if you’ve heard of a site called “3D Buzz”, but their content could be of interest to anyone in the CAD field.

Do you know the difference between the terms “FDM” and “FFF”? From what I read, it seems a large number of people are not aware of their true meaning.

I’ve found a source with a ton of CAD utility recommendations that could make life easier for anyone using 3D CAD to create designs for 3D printing.

I encountered an unusual support structure issue while 3D printing and propose several ways to resolve it with Meshmixer.

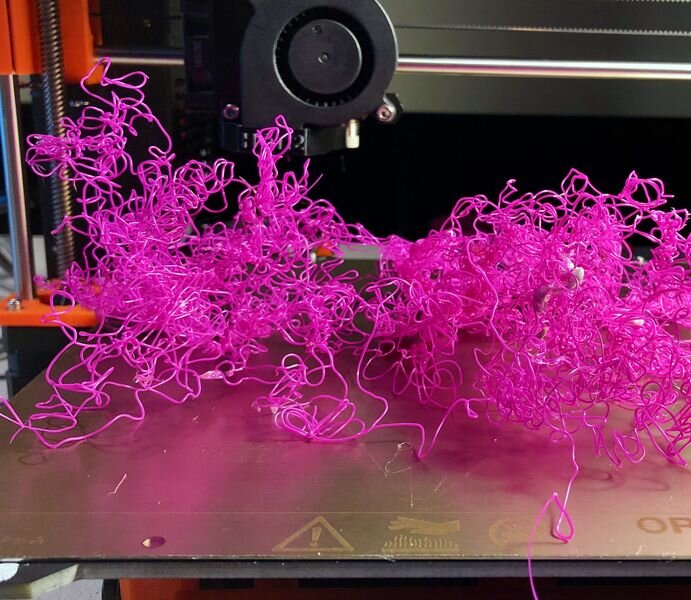

Of all the 3D printing issues you can encounter, bed adhesion, or lack of, is one of the most frequently seen. We list seven ways this can happen and offer suggestions on how to avoid them.