This is an entry in our 3D Print Learning Series, focusing on 3D print concepts.

For other current entries in this series, please search for our tag, “learning series”, here. Search often, as we will be adding more periodically.

3D Printing Concepts

The concept of 3D printing is quite different from conventional manufacturing, which is a subtractive process: material is removed — by cutting, milling, etc. — to reveal the desired object. In 3D printing it’s quite the opposite: you start with nothing and gradually add material to form the final object.

There are several key advantages to do so, mainly that there are virtually no geometric constraints on the shape of the item being printed, as the object is typically created layer by layer. Impossible shapes, like the “ship in a bottle”, are easily created.

Some in industry have leveraged these properties of 3D printing to create radically new components and products of vastly improved efficiency, cost and performance, particularly in the aerospace, medical and automotive areas.

But what are some key learnings about 3D printing? Let’s find out: each headline here is a link to the relevant topic.

In 3D Printing, Temperature Counts

![Lousy 3D print layer adhesion [Source: Dubious Engineering]](https://fabbaloo.com/wp-content/uploads/2020/05/temperature_result_img_5eb09cd7883d5.jpg)

Temperature is a critical factor in several of the most popular 3D printing processes, and in particular thermoplastic extrusion. This post explains some of the challenges with incorrect temperatures.

The Several Methods Of Dual Extrusion

![One form of dual extrusion [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/dual_result_img_5eb09cd7b2122.jpg)

Dual extrusion is a popular method of achieving more than one material (or color) within a single 3D print job. However, there are multiple ways of doing this, and some are clearly better than others.

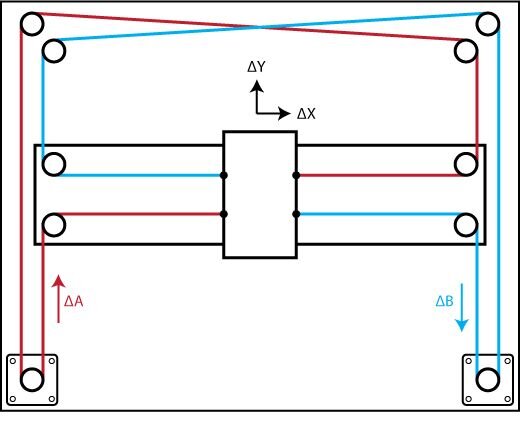

Is X-Y Resolution Important In 3D Printing? Answer: Sometimes

Measurements of resolution are a bit strange in 3D printing, where often the layer size (Z axis) is specified. However, there are two other dimensions, X and Y, that should also be considered.

Electrostatic Discharge Explained

![ESD Paths [Source: Foam Fabricators]](https://fabbaloo.com/wp-content/uploads/2020/05/esd_result_img_5eb09cd815441.jpg)

When working with desktop 3D printers there is a danger of electrostatic discharge if you are not careful. “ESD” can irreparably damage a 3D printer if it is not properly engineered.

The Good, Bad And Ugly Of Using Rafts When 3D Printing

![A very fat 3D print raft [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/rafts_result_img_5eb09cd8422e2.jpg)

Rafts are a diabolical thing in thermoplastic 3D printing. They can be incredibly frustrating, tedious and disruptive, but at the same time they can save a print from complete failure.

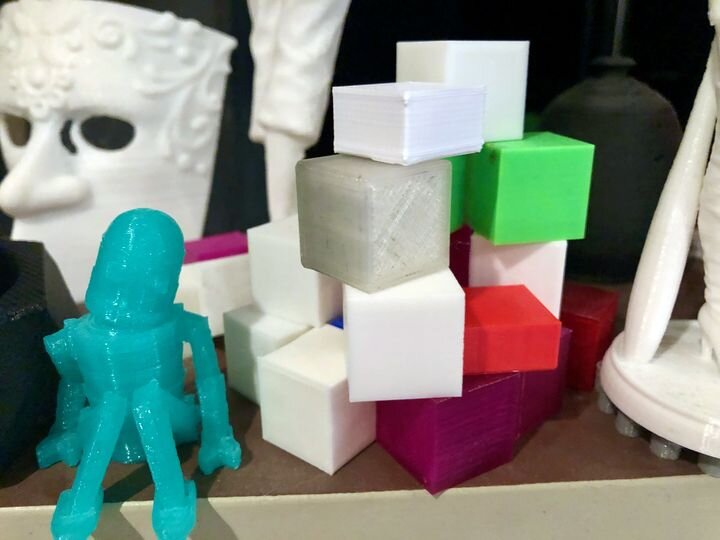

Dialing In A 3D Printer? What’s That All About?

![Iterating through 3D print parameter values [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/dialing_result_img_5eb09cd86d853.jpg)

Frequently a new desktop 3D printer may not have appropriate print settings, result in less than optimal quality print, or worse, complete failure. The answer is to “dial in” your 3D printer.

How To Print Tall Without A Tall 3D Printer

![Short and tall 3D prints [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/tall_result_img_5eb09cd8955be.jpg)

A very common question is “How Big Can I 3D Print”. The answer is thought to be related to the size of the printer’s build chamber, but that’s actually quite wrong.

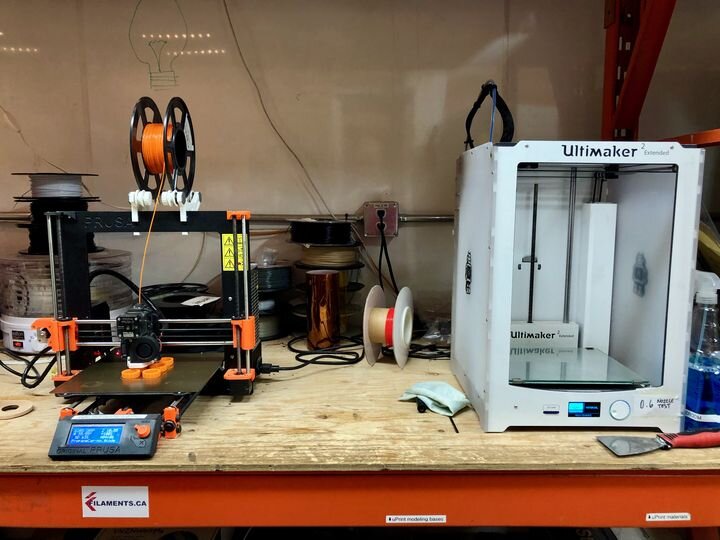

The Desktop 3D Printer Toolkit

![Some 3D print accessory tools [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/toolkit_result_img_5eb09cd8c1e68.jpg)

You’ve obtained a 3D printer. But is that all you need? It turns out you probably should have a number of other accessory tools that will make 3D printing life considerably easier.

The Insidious Problem Of 3D Print Retraction

![Retraction in action simulation [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/retraction_result_img_5eb09cd8ebf88.jpg)

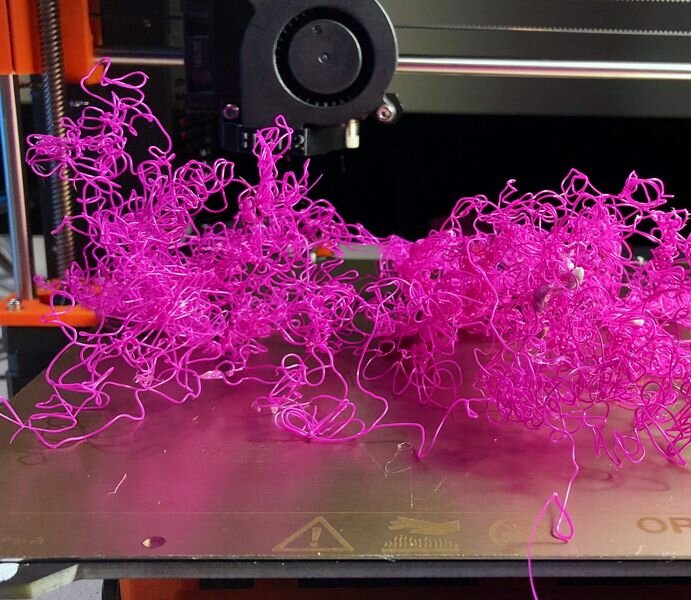

When 3D printing with a thermoplastic extrusion device a phenomenon known as “Stringies” can occur, messing up print quality quite terribly. They can be controlled by means of a particular print parameter, “retraction”.

9 Things You MUST GET RIGHT Before 3D Printing

![Abruptly stalled 3D print result [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/9things_result_img_5eb09cd922b88.jpg)

If you have less experience with 3D printing, you’ll no doubt have much grief getting prints to work. But there are several things you absolutely must do before you even attempt 3D printing if you hope to succeed.

How To: Persistent 3D Print Failure? Here’s What To Look For

![Failed 3D print [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/persistent_result_img_5eb09cd94f219.jpg)

Thermoplastic extrusion 3D printers are very sensitive to several factors that can contribute to or cause 3D print failures. Let’s look at them to ensure our print jobs will work properly.

Bigger Nozzle Equals Faster Printing

![A big 3D print [Source: 3D Platform]](https://fabbaloo.com/wp-content/uploads/2020/05/bignozzle_result_img_5eb09cd97996c.jpg)

3D prints can be extremely long in duration, particularly when the prints are larger. But there is a relatively easy way to speed up 3D prints, making more efficient use of the equipment.

An Introduction To Support Structures

![Support structure example [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/support_result_img_5eb09cd9bceb0.jpg)

Some 3D models simply cannot be 3D printed on many 3D print processes without the use of extra “support structures” that help hold the print together until it’s complete. What are they and how do they work?

Shrinkage: A Problem Of 3D Measurement

![Differently sized prints [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/shrinkage_result_img_5eb09cd9eac58.jpg)

As described above, temperature is a critical factor in 3D printing. It turns out that heat and cold can expand or shrink many materials, making the precise dimensions of your print wrong.

Bowden Or Direct? A Primer On Extruder Styles

![A bowden extruder [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/bowden_result_img_5eb09cda28c06.jpg)

Thermoplastic extrusion 3D printers employ two basic mechanisms to drive filament to the hot end. Each has advantages and disadvantages that may be applicable in different circumstances.

More Learning

For other currently entries in this series, please search for our tag, “learning series”, here. Search often, as we will be adding more periodically.

CoreXY is becoming a very popular approach for 3D printer motion systems, but is it the ultimate answer? We list the advantages and disadvantages.

VSHAPER has released a pair of interesting 3D printing guides, and unlike most beginner guides, these are designed for engineers.

I’m not sure if you’ve heard of a site called “3D Buzz”, but their content could be of interest to anyone in the CAD field.

Do you know the difference between the terms “FDM” and “FFF”? From what I read, it seems a large number of people are not aware of their true meaning.

I’ve found a source with a ton of CAD utility recommendations that could make life easier for anyone using 3D CAD to create designs for 3D printing.

I encountered an unusual support structure issue while 3D printing and propose several ways to resolve it with Meshmixer.

Of all the 3D printing issues you can encounter, bed adhesion, or lack of, is one of the most frequently seen. We list seven ways this can happen and offer suggestions on how to avoid them.

We were able to view video footage of the 3D printing hair-caught incident from last week and have determined exactly how it occurred, and how to prevent it from happening again.

Everyone talks about “3D printer calibration”, but what is it really? We believe the process varies considerably depending on a number of factors.

We witnessed yet another dangerous situation encountered by a 3D printer operator and provide some advice on how to avoid the situation.