Charles Goulding and Andressa Bonafe discuss innovations in smart fabrics that might be impacted by 3D printing.

Recent developments in the technology, textile, and apparel industries have enabled previously unimaginable interactions with fabric-based products, which include data collection and communication through embedded sensors and conductive yarns. Even though major technology companies, including Google and Apple, have taken a growing interest in smart fabrics, the viability of large-scale production remains a challenge. Additive manufacturing is bound to play an increasingly central role in this emerging market, as innovative companies begin to print electronics and sensors as integral parts of fabric.

The Research & Development Tax Credit

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

-

Must be technological in nature

-

Must be a component of the taxpayer’s business

-

Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

-

Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include U.S. employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, U.S. contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum tax for companies with revenue below $50MM and for the first time, pre-profitable and pre-revenue startup businesses can obtain up to $250,000 per year in payroll taxes and cash rebates.

Google’s Jacquard

Google has pioneered a new approach to wearable technology that aims to give people access to the digital world through apparel. The company developed conductive, extremely thin metal alloys that can be combined with a variety of natural and synthetic fibers. Google’s Jacquard looks, feels, and performs like normal yarn and can thus be woven using traditional techniques and equipment. Though offering next-generation connectivity, Jacquard textiles are indistinguishable from regular ones and can be integral parts of any design (see image at top of article).

Paired with a full-scale digital platform, Jacquard textiles can understand and interact with electronic gadgets. They allow users to instantly and effortlessly access digital capabilities through different touch and gestures without having to reach for their phones or any other devices.

Google partnered with Levi Strauss & Co. to create the first product incorporating Jacquard. The groundbreaking Commuter Trucker Jacket adds a new layer of connectivity and interactivity to everyday clothing. The Jacquard-enabled garment allows users to customize gestures and abilities, meaning that they can choose which commands to assign for which service. Abilities are expandable and currently include communication (handling calls and texts), navigation, and music.

Apple’s Fabric-Related Patents

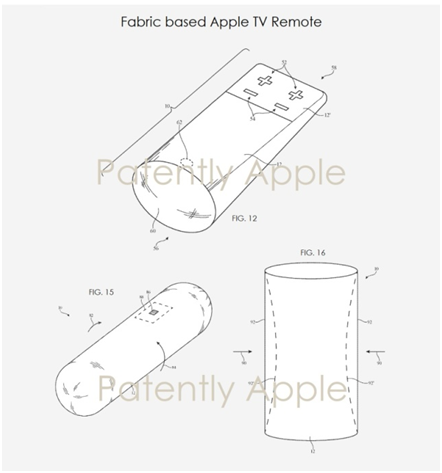

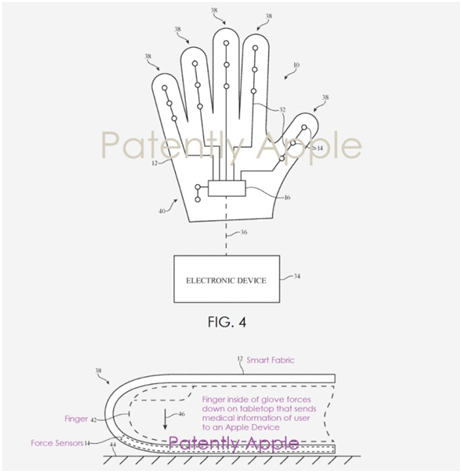

Apple has been awarded a series of fabric-related patents, generating rumors and expectation regarding the possible use of smart fabrics in new products. One of these patents describes circuit-infused gloves that could enable health-related applications, such as the monitoring of blood pressure, heart rate, and respiration. The Daily Mail reported that the patent refers to “force sensing circuitry” and “intertwined strands of material including conductive strands”. Another patent covers fabric-based items, including device housing and accessories. It presents a perspective view of a fabric-based Apple TV remote control with deformable walls that can compress inwardly.

Apple’s Patents Illustrations – Remote Control and Glove

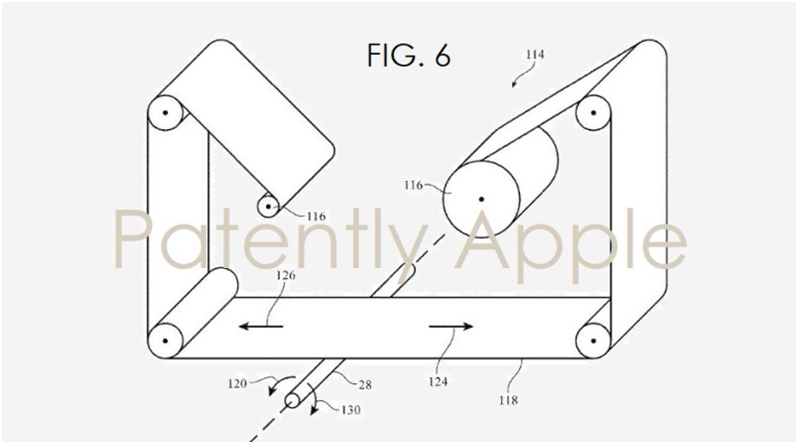

On January 8, 2019, Apple was granted yet another patent for specialized equipment to make regular and smart fabrics. The company has listed numerous potential applications, including clothing, smart glasses, wrist bands, headbands, and even sofa cushions. According to Patently Apple, the recent patent underlines Apple’s interest to custom manufacture smart fabrics to meet its specifications and standards.

Tommy Hilfiger

Tommy Hilfiger’s new line of smart clothing, Tommy Jeans Xplore, sheds light on how smart fabrics can be used in marketing and customer loyalty strategies. The collection is embedded with Awear Solutions’ Bluetooth low energy smart tag. It includes t-shirts, sweatshirts, hoodies, jeans, jackets, caps, and bags that pair with the Tommy Jeans Xplore iOS app and reward users for how often they wear the clothes. Points can be exchanged for gift cards, signed merchandise, etc.

3D Printing and Smart Fabrics

Additive manufacturing has enabled significant advancements in the apparel industry and it will likely become integral to the development and widespread application of smart textiles.

Headquartered in Israel, Nano Dimension is among the world’s leading additive electronics provider. The company’s award-winning DragonFly Pro System for precision additive manufacturing of printed electronics can simultaneously 3D print dielectric polymer and conductive metal. It enables the 3D printing of functional electronics essential to various industries, which can be prototyped quickly and securely in-house, with lower costs.

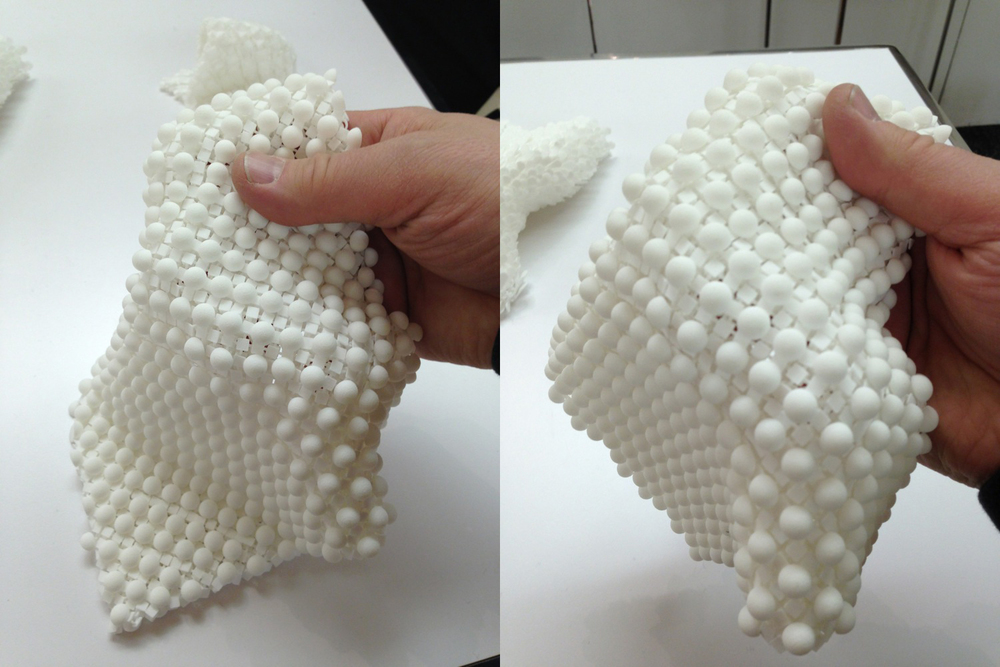

In 2016, Nano Dimension’s wholly owned subsidiary, Nano Dimension Technologies Ltd., successfully printed conductive traces onto a treated fabric. After numerous tests that assessed aspects such as the conductivity, elasticity, and rubbing of the final product, the company identified silver conductors that presented high enough elasticity to match fabric properties. The smart fabric utilized Nano Dimension’s AgCite Silver Nanoparticle conductive ink and the DragonFly 2020 3D printer platform.

The Way Forward

Recent advancements in smart fabrics promise to bring unprecedented interactivity and connectivity to clothing and other fabric-based products. According to Nano Dimension, the smart textile market will reach $4.72 billion in 2020, finding applications throughout various industries. 3D printing will undoubtedly be an integral part of this revolutionary trend. All new apparel designs, and especially smart clothing, should be subject to rigorous testing. In that regard, Adam Varley of Vartest, the leading New York City-based apparel-testing firm, points out:

“Since smart textiles and 3D printing for apparel are new technologies, product performance specifications relating to them are in their infancy. Both ASTM, the American Society for Testing and Materials and AATCC, the American Association of Textile Chemists and Colorists, have consensus-based committees actively working on Smart Textile standards. Standards relating to connectors and performance after washing are of particular interest.”

1 comment

Comments are closed.