There’s a bit of a craze underway with several people exploring the process of 3D printing on fabric.

This is not a new thing; we wrote about it in 2016, as someone was experimenting with the technique at that time. But for some reason it did not catch on.

Now, it may have as a result of designer David Shorey, whose experiments have gained quite a few followers recently.

Shorey has taken many interesting steps forward in refining this process, but it all starts with a relatively straightforward few steps:

- 3D print the first couple of layers of a design

- Pause the print, moving the toolhead out of the way

- Lay a thin fabric on top of the partial print, tacking it down tightly

- Resume the print

- Subsequent layers are affixed to the previous layers because the plastic soaks through the thin fabric

- The resulting 3D printed object is thus embedded in the fabric

This does sound like a lot of fun, but there seems to be far more to the story.

It isn’t quite as simple as listed above, however, as Shorey and his growing entourage of investigators have done quite a bit of experimentation with different materials. PLA appears to be the popular choice for plastic, as the applications of this technique don’t usually require extreme engineering properties.

There has been much work done on selecting the right material for this approach. Some materials are too thick, preventing proper adhesion between the layers and the fabric. Others have been too thin and tear easily. While some are using a mesh-like material called “Tulle”, Shorey has found it too weak and now recommends nylon mesh, at least as of this writing.

One fan has produced a short video explaining how this is done:

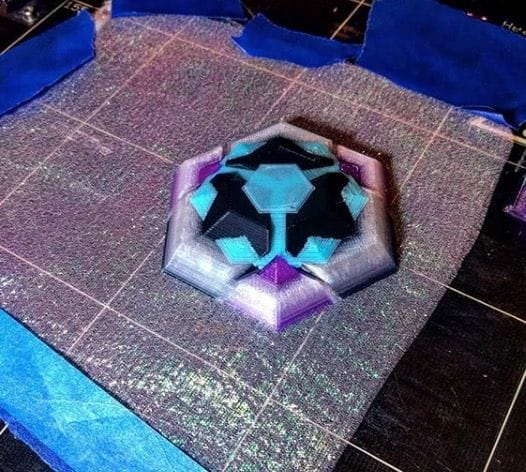

Shorey has produced some very intriguing results. Here are some of the twists he’s investigated so far:

Printing multiple small objects to form “scales” or similar surfaces

Printing large, 3D objects to form very interesting fabric attachments

Printing in multiple colors

Printing in graduated colors

Installing lights under the fabric prints

Company logos

Inserting mirrors during the print

I think you get the idea: the possibilities are endless and limited only by your imagination.

Use of these fabric segments could be for cosplay, as Shorey is pursuing, but also for fashion. It would certainly be possible to design fantastic attachments that would be incorporated into clothing.

It’s also possible this technique could be used in a functional way. Imagine, for example, a designed tool holder designed to hold a particular type of item. This could be attached to a uniform. In fact, you might 3D print a custom set of holders for a specific mission.

One could even imagine a machine designed to do this. Or perhaps a hardware attachment for existing 3D printers. Imagine a kind of conveyer system that would pull a sheet of fabric across the print plate at the right moment, automating the process. Something like that could be designed to fit many 3D printers designs.

I think this approach requires a lot more investigation, as there may be some big possibilities here.