A 3D printed electrical circuit by Zortrax is set to take off on a unique wooden satellite.

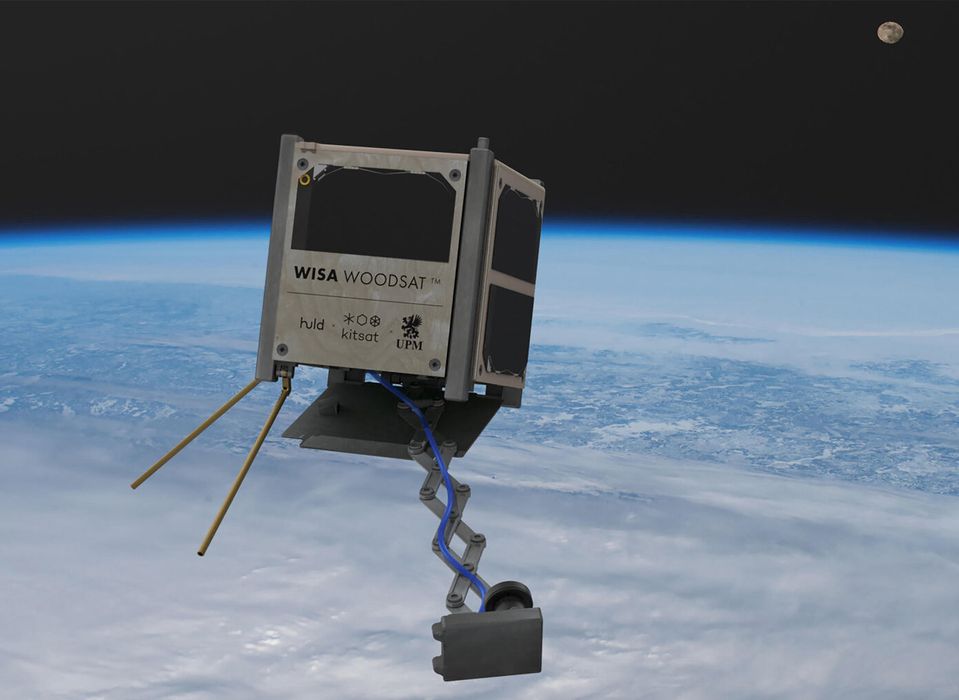

The WISA Woodsat is an experimental CubeSat that be placed in orbit early next year on a RocketLab Electron vehicle. The most notable aspect of this unusual mission is that the CubeSat (a 10 x 10 x 10 cm standard size) will be made largely from plywood.

The project was conceived by Finnish broadcaster Jari Makinen, whose company, Arctic Astronautics, produces working replicas of actual CubeSats for training use. Apparently he got the idea of making a CubeSat out of wood, and over time the project caught the interest of ESA and others. Eventually, commercial support was obtained (some from UPM Plywood, a major manufacturer of plywood, and the project began in earnest.

While the birch wood in the Woodsat is the key element, it turns out there are other materials under test.

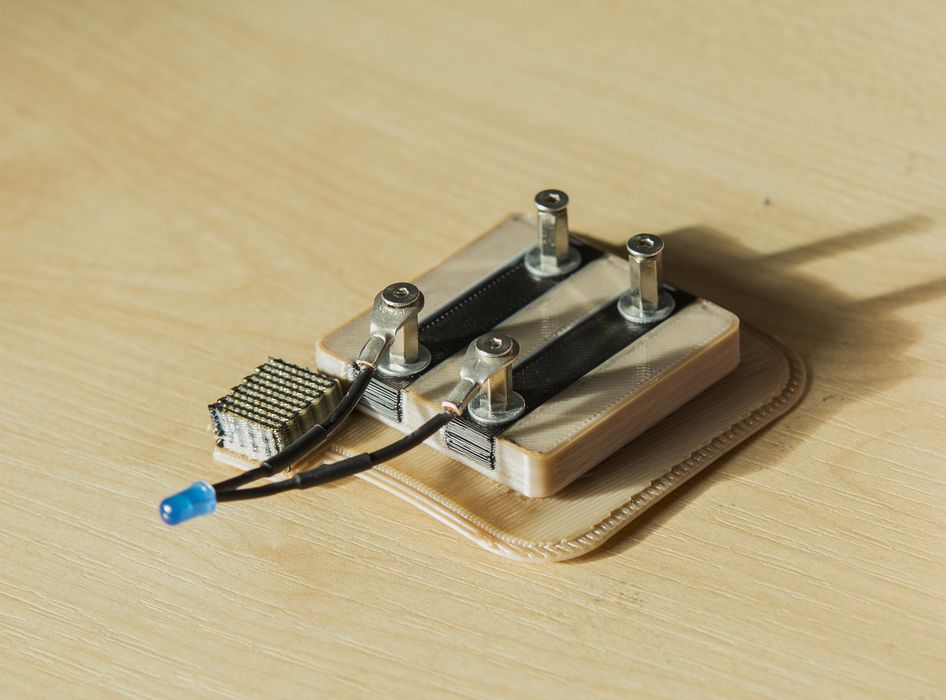

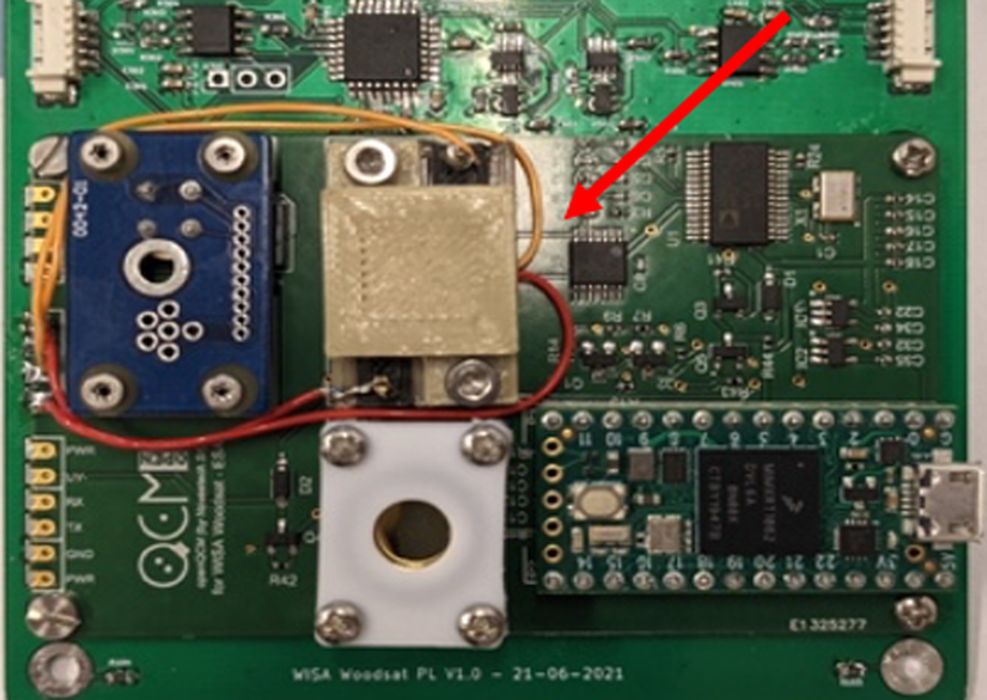

ESA wanted to piggyback on the project and test a 3D printed circuit made from PEEK. In fact, it was a very special PEEK designed by ESA themselves, and it is electrically conductive.

Zortrax explains:

“The demo circuit that is going to be tested on orbit is made with two blends of PEEK, one of the strongest polymers on the planet. The body and cover of the demonstrator is made with standard Z-PEEK material offered commercially for the Zortrax Endureal 3D printer.”

The conductivity in the special PEEK material is obtained through the inclusion of carbon nanotubes that convey the electrons through the material.

I’ve just realized that it is now entirely appropriate to launch this thing on an Electron rocket.

ESA partnered with Zortrax to produce the part on their Endureal 3D printer. They took advantage of the machine’s dual extruders to 3D print the circuit using two different PEEK materials in the same job.

Zortrax CEO Mariusz Babula said:

“WISA Woodsat is a unique mission focused on testing new materials and groundbreaking manufacturing technologies in space industry. Several parts of this CubeSat are made of birch wood covered with a special kind of coating that is supposed to protect it from space environment effect. It will be launched onboard a partially recoverable Electron rocket which has large parts of its body fabricated with lightweight carbon composites. Obviously, flight-testing 3D printed PEEK polymeric based electrical circuits for the first time in history fits great in the overall theme of this groundbreaking mission. We believe that innovative materials and additive manufacturing will make space more accessible and easier to reach for businesses and scientists worldwide. And Zortrax has a major role to play in shaping this future.”

It’s important to remember that this is just an experiment; it’s not known what the outcome might be. However, it’s possible they may find that 3D printed circuits are useful — and lightweight — and we may find them in spacecraft of the future.

Wooden spacecraft of the future, that is.

Via Zortrax