Yizumi’s SpaceA industrial 3D printer combines several technologies into an interesting package.

Yizumi is a large Chinese company with offices in USA, Brazil, Vietnam, Thailand, India and Germany, producing a wide variety of manufacturing equipment, including injection molding of polymers and metals, robotics, die casting, and now, 3D printing. In their history they’ve apparently sold over 50,000 machines worldwide.

We had a look at their sole 3D printing solution, the SpaceA Industrial 3D Printer.

This is a true manufacturing device, designed for continuous production of polymer parts.

As you can see in the above image, the SpaceA uses a robotic system to deposit softened polymer in the required geometry, layer by layer.

You’ll also notice that the print surface is actually a conveyor belt. This makes the SpaceA device perhaps the only robotic belt 3D printer available.

The belt approach allows the machine to produce objects continuously. As the belt moves forward, prints peel off the belt and fall into a collection bin for further processing. We saw this in action, and the SpaceA does indeed produce endless quantities of parts. Yizumi representatives said the belt feature is actually an option, as the SpaceA can be set up in a variety of configurations.

What you don’t see is the nature of the materials being used.

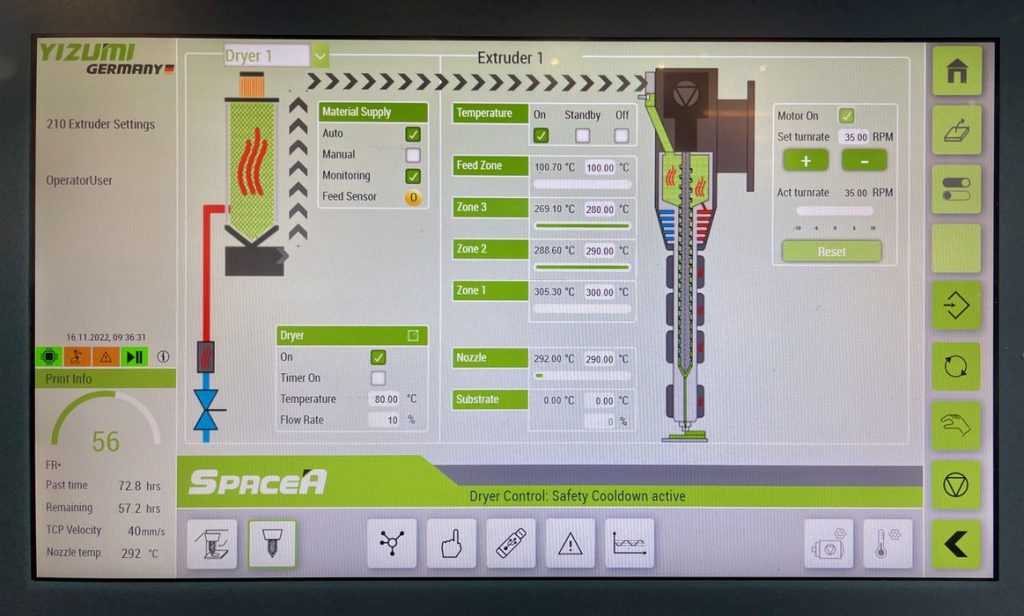

First, the materials are provided to the SpaceA in the form of pellets. This is a highly economical method, as filaments tend to cost far more than pellets. That’s advantageous when printing large quantities of parts, as the SpaceA is intended to do.

Yizumi is primarily a manufacturer of injection molding equipment for both polymers and many metals. Their expertise in that field has been brought to the SpaceA, as its extrusion system is able to use a wide range of materials. In fact, the machine can use “general injection molding materials”, which number in the thousands.

That’s quite different from many 3D printers, which have quite constrained lists of usable materials.

That’s a powerful capability, and fits well into the workflow of injection molding companies. The ability to 3D print objects rather than using expensive molds enables many companies to take on smaller jobs that would otherwise be financially infeasible. They say it’s an “alternative extension to injection molding”.

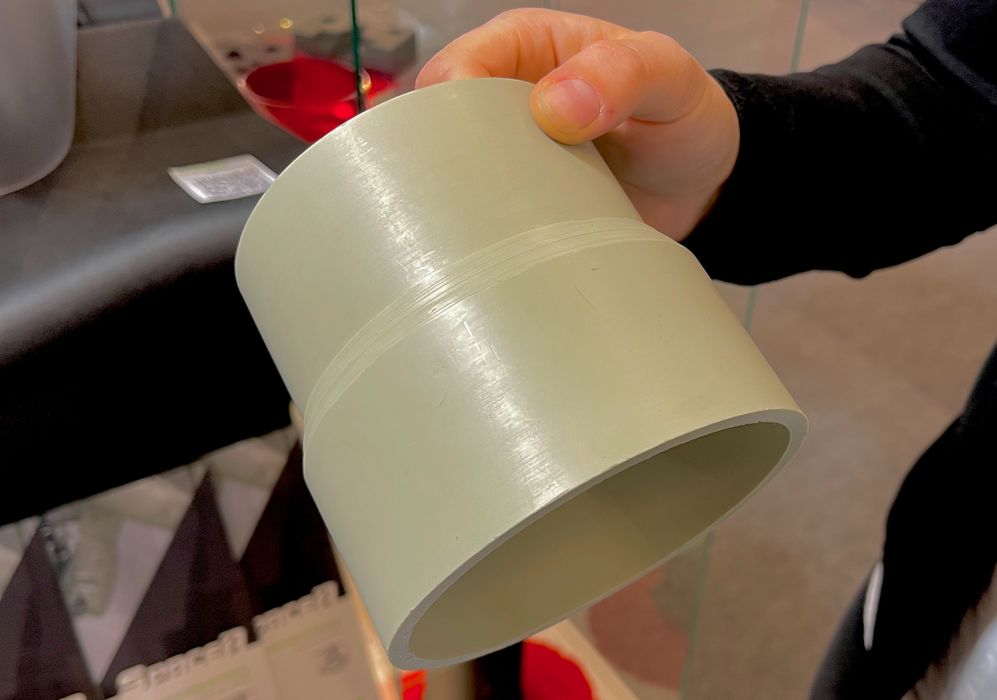

The print quality is a bit coarse on the device, as you can see in the images here. However, that’s not a bother for many applications that tend to have larger sizes. Pipe fittings, furniture, auto parts and similar are easily made on this device, and in low volume quantities.

The SpaceA 3D printer holds quite a few impressive capabilities and technologies that could be of interest not only to injecting molding companies, but any manufacturer looking to do low volume production of parts using standard injection molding materials.

Via Yizumi