Xometry has provided a plug-in for direct integration with Autodesk Fusion 360.

Xometry is a rapidly growing manufacturing network that provides an easy-to-use interface on the front side, but on the inside they connect with a wide variety of professional manufacturing workshops. Your production request is automatically routed to one of them for fulfillment.

Now the manufacturing network has launched a new plug-in that extends the functionality of Autodesk’s very popular Fusion 360 modeling tool.

Normally you would have to export your 3D model from Fusion 360 to a file, then upload it to Xometry to obtain a quote for production. Instead, the plug-in makes things far easier.

I installed the Xometry plug-in on my copy of Autodesk Fusion 360 to see how it worked. This is easily done by downloading an installation file from the link below and giving it a click.

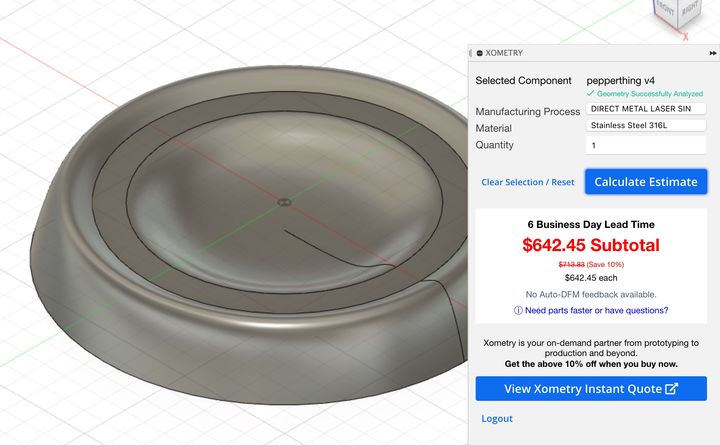

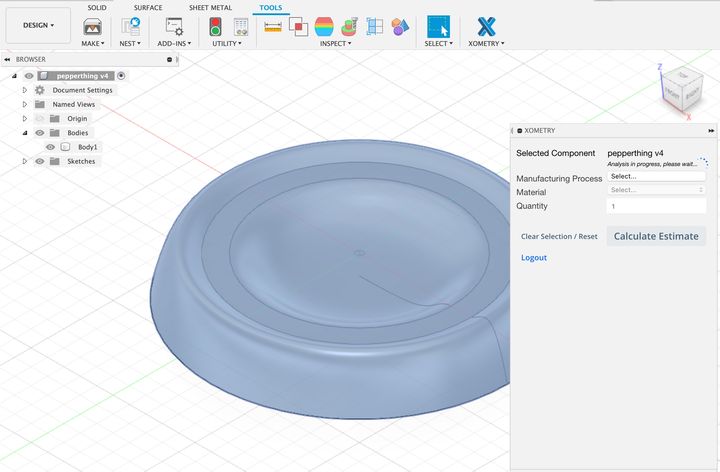

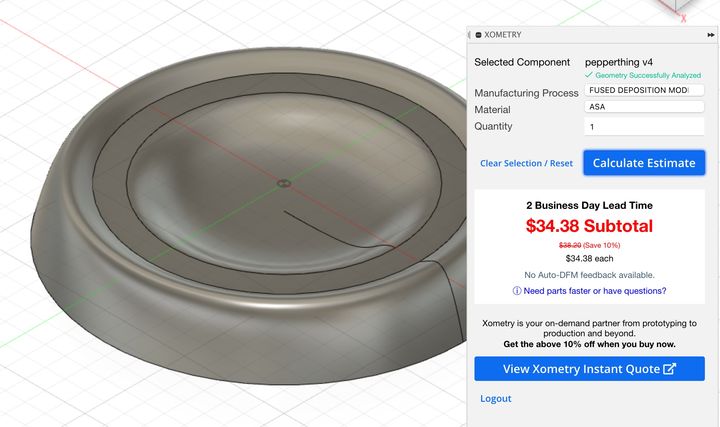

Once installed, you can restart Fusion 360, and open a model. I chose something I’ve been working on, a small dish-like model that is intended to sit under a pepper grinder and collect stray bits as they inevitably leak out of the grinder.

Then to activate the plug in you must go to the Tools submenu, select “ADD-INS”, and start up the Xometry plug-in. This causes the Xometry icon to appear in the Fusion 360 toolbar.

The toolbar menu item launches the plug-in, and the first thing you must do is login to Xometry. If you don’t happen to have an account, they allow you to register one, and you can do so without any payment.

Once logged in you can select a 3D model for production. This provokes the Xometry system to perform an analysis of your geometry, which can take a moment or two to complete.

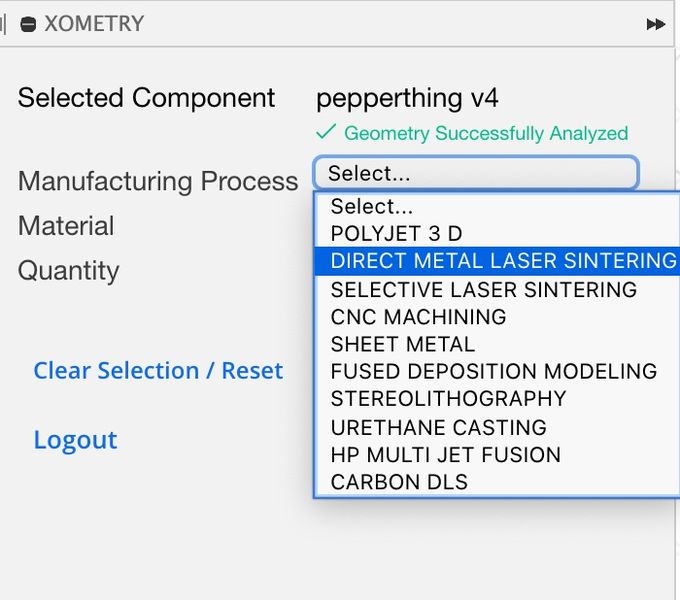

Then you’ll have to specify the means of production, as Xometry offers several making processes, including:

- PolyJet 3D

- Direct Metal Laser Sintering (DMLS)

- Selective Laser Sintering (SLS)

- CNC Machining

- Sheet Metal

- Fused Deposition Modeling (FDM / FFF)

- Stereolithography (SLA)

- Urethane Casting

- HP Multi Jet Fusion (MJF)

- Carbon (DLS)

That’s seven different 3D printing processes and three conventional making processes to choose from.

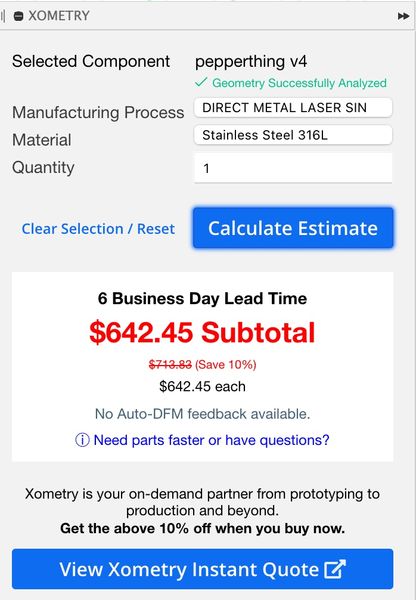

After selecting the manufacturing process, you’ll have to select the material, which, as you might guess, is tightly related to the manufacturing process. You’ll also specify a quantity, which defaults to “1”. Xometry very quickly calculates an estimated cost for the job, and also provides the expected delivery period.

The pricing varies widely depending on what you choose. To 3D print my pepper thing in 316L stainless steel using DMLS the charge would be US$642, while the same model in ASA using FFF would cost only US$34, 18X less expensive. But the cost is secondary to functionality: choose the process and materials that meet the engineering requirements.

Once you’ve landed on the correct configuration, it’s a simple matter to hit the button and production begins.

This is a great step for Xometry, as it provides massively simpler access to their services directly from a CAD system. One of my theories is that if you want someone to do something, remove the barriers, and that seems to be what Xometry is doing here.

If you’re a Xometry client (or thinking of becoming one) and you also use Autodesk Fusion 360, this would be an ideal plug-in to save some time.