Resin 3D printing isn’t nearly as popular as FFF 3D printing even though it’s widely available. Why is that so?

Most desktop 3D printer operators begin with FFF-style 3D printers, which use spooled filaments as their material. These machines work reasonably well, and can be coaxed into producing useful objects by even beginning operators. There are literally hundreds of FFF desktop 3D printer options on the market today.

However, there are also large numbers of resin 3D printers on the market.

Resin 3D printers offer a number of significant advantages over FFF 3D printing:

- They produce output that’s superior in quality, particularly smooth surface finishes

- They operate silently

- They can produce objects with extremely fine resolution, suitable for small items like jewelry

- They can use a wide selection of materials that includes not only polymers, but also ceramics

- They typically occupy a very small footprint on a desk or table

- They can produce thermoset polymer objects that can have higher thermal resistance

With those advantages listed, it might be curious why there are so few resin 3D printer operators as compared to FFF 3D printer operators.

It turns out there are also a number of disadvantages, some of which are significant. Let’s take a look at the most important factors.

Resin 3D Printing Can Be Complex

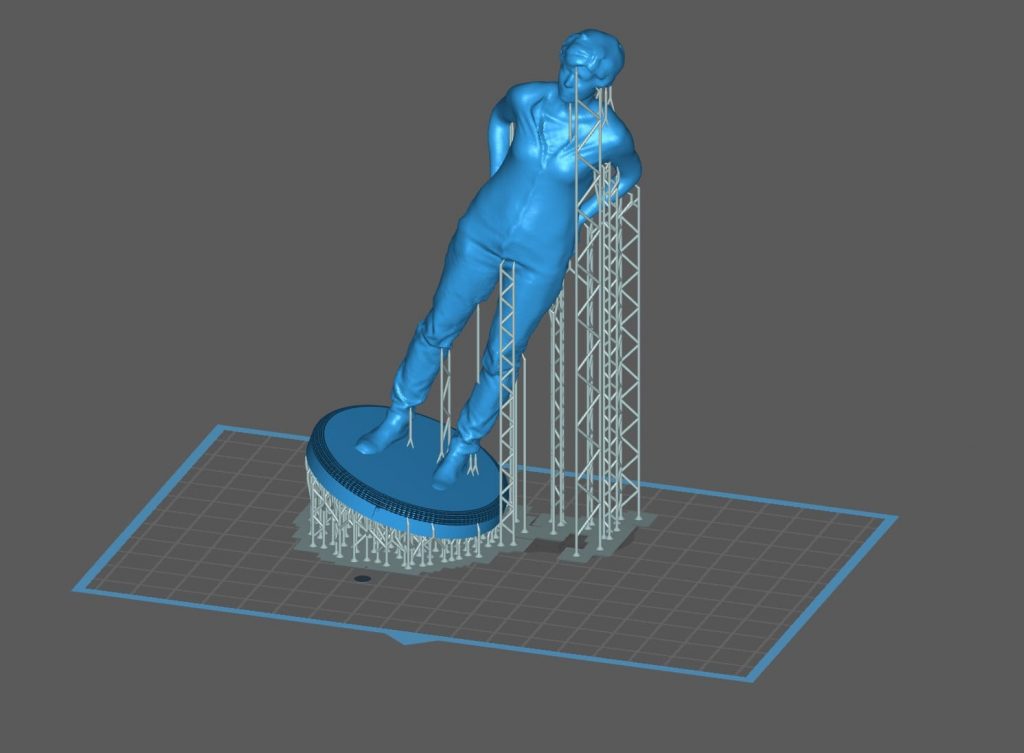

You just hit the “print” button? No, it’s actually much more complex than that, and it all has to do with support structures.

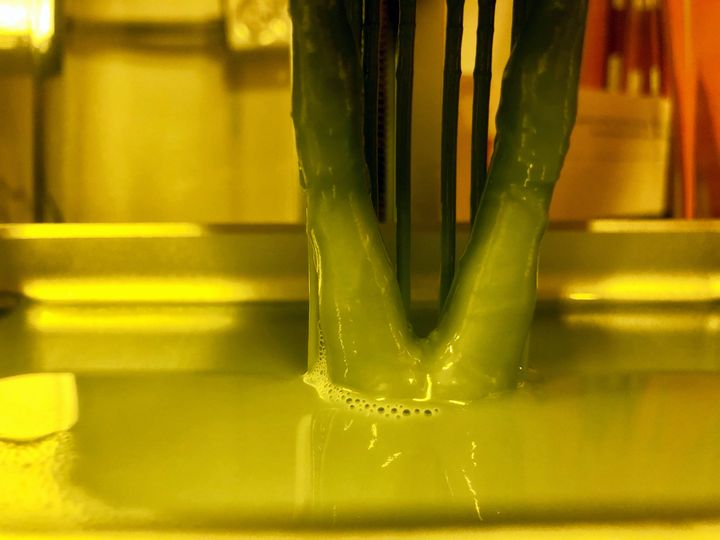

Freshly solidified resin is still quite weak and it bends easily. Thus when you 3D print an object it hangs from the build plate and undergoes stress from gravity and peeling new layers off the resin tank bottom. These stresses can bend the print into unintended geometries, or even cause the print to fail entirely.

This means significant amounts of support material are required. But hold on, aren’t they automatically generated? They are, but in many resin slicing software systems, the automatically generated supports are terrible. They can be too dense, causing surface quality issues, or too sparse, causing the problems described above.

In many cases the operator is forced to tediously design a unique support structure for the object, and sometimes this takes several iterations to get it correct.

3D printer operators coming from the FFF world believe support structures are similar. They are not, and require an entirely different state of mind to achieve success.

Resin 3D Prints Can Be Weaker

While resin 3D prints can be of higher quality and resolution, they can be weaker than equivalent parts produced on FFF systems. Partly that’s because of the material types, but it’s also from the polymerization process, which sometimes doesn’t produce as strong bonds.

There’s another effect: UV light. That type of light is used to initially solidify the resin in the desired geometry, but it’s also used to cure the part after 3D printing completes. This is usually done in a separate UV chamber.

The problem is that if the 3D printed part is used outdoors, it’s then exposed to even more UV light from the sun. This UV light continues to cure the object, and that can generate problems. Poor quality resins will actually result in cracked 3D prints after repeated UV exposure. It’s like you’ve cured the object too much.

Resin 3D Printing Is Messy (and Toxic)

Finally, resin 3D printing is a messy affair using typically toxic fluids. Most photopolymer resins have toxic chemicals used for the solidification process. After polymerization the objects are perfectly safe, but in liquid form they can be toxic when exposed to the skin or lungs. This toxicity typically manifests after repeated exposures, so resin 3D printer operators may be lulled into thinking “it’s OK.” It’s not.

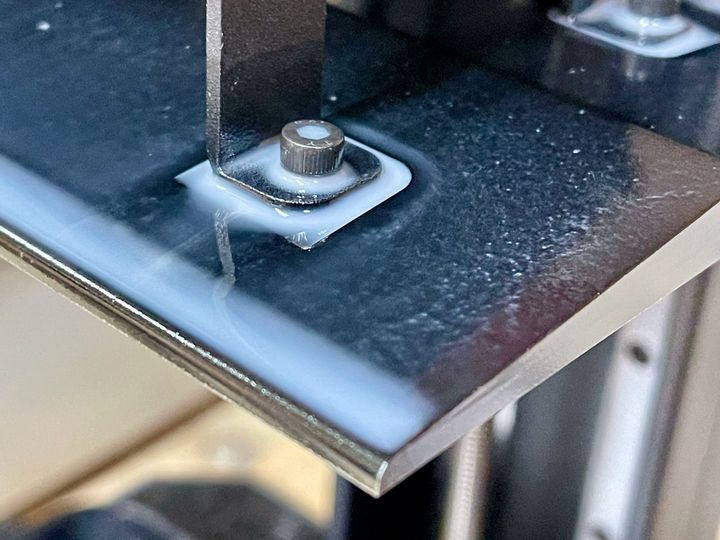

The toxicity demands that resin 3D printer operators always use suitable disposable gloves and eye protection when handling the resin.

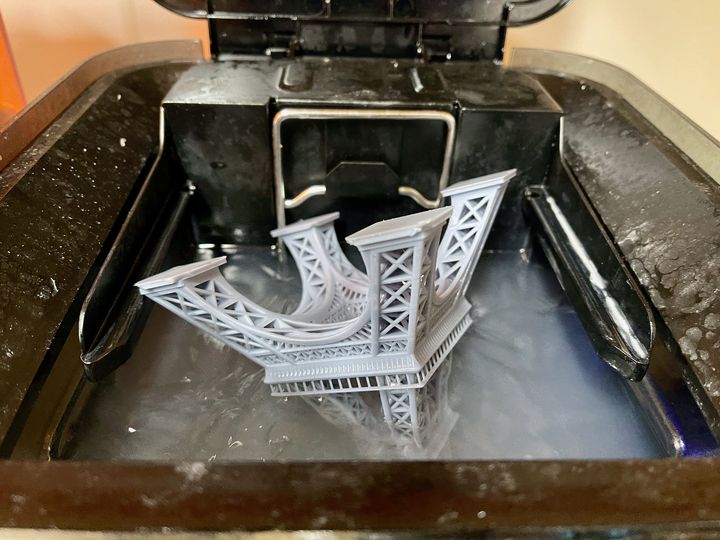

A required post-processing step for a resin 3D printer is to wash off the remaining toxic liquid resin. This is usually done with an IPA bath, but some resins can be washed with plain water.

This wash transfers the liquid resin off of the print and into the wash fluid. Now you have a tank of toxic fluid, water or IPA. Even worse, IPA is quite flammable, requiring additional safety measures.

Should You Use Resin 3D Printers?

After all this information, you might be re-considering your plan to use a resin 3D printer. I recommend continuing to use resin 3D printers, but always with the knowledge that they are quite different from FFF 3D printers and require very special handling.

Many people successfully operate resin 3D printers with workflows quite different from FFF machines. You can do so too, if you treat resin 3D printers differently.