I’ve been wondering why PLA is still the most popular 3D printing material, and have some thoughts.

Way back in 2009 when the first inexpensive desktop 3D printers appeared after the expiration of the key Stratasys patent, there were no suppliers of “3D printer filament”. The answer was to use welding wire, made of ABS. This was chosen because it is commonly available, and thus enabled the initial buyers to have at least one type of material to print.

Of course, we now know that material was terrible. Welding wire had poor quality control — at least in terms of 3D print usage — and ABS itself is challenging to print due to its tendency to warp, particularly in the open gantry machines of the day.

Then a short while later the idea was to use PLA instead of ABS. The introduction of PLA was a revolution to the industry. It provided a way to print far, far more reliably on crappy, open gantry 3D printers, because it didn’t warp very much at all.

It turned out that people actually use 3D printers that work, and many more machines were sold because of this single change.

Thus PLA gained a tremendous amount of momentum in the industry. Suppliers popped up and began marketing wide selections of PLA in different colors and even mixes with unusual substances like coffee, algae and even metal particles. While some of those products were “stunts”, the point is the industry bloomed when PLA became established.

That situation persisted for a few years, but then we began to see the introduction of more advanced materials. PETG, TPU and even nylons began to appear on filament supplier lists, and even more exotic materials came later.

While some of the exotic materials require specialized 3D printer features, such as enclosed chambers, unusual adhesion systems or high temperatures, there is now more choice of materials for everyday 3D printers than ever before.

You can print PLA, ABS, TPU, PETG, PCTG, PHA, and many other materials on practically any inexpensive 3D printer on the market today.

But then why PLA?

PLA is now not the greatest material available, although it does have the widest choice of colors today. It’s a material that has an extraordinarily low softening temperature, making it in appropriate for many applications. It does warp slightly, so larger prints can suffer, and it doesn’t adhere quite as well as some other common materials.

In speaking with Luke Taylor of Polymaker, we learned that they believe most ETSY stores producing 3D printed products simply use PLA routinely. Taylor said there is a “thirst for PLA” that seems insatiable. He reports that all of Polymaker’s PLA lines are selling very well to this day.

My thought is that a growing majority of the operators of inexpensive 3D printers today are relatively less technically informed than the initial group of hardcore operators. We also have large groups of small farms doing low volume production for platforms such as ETSY. These operators represent a significant amount of material consumption, as they print constantly as opposed to casual consumer operators.

This new majority group is likely far less comfortable with changing to different material types, as it would potentially require re-tuning their print parameters and possibly upsetting their busy production schedules. Why change something that already works?

The root cause, however, is most likely the 3D printer manufacturers themselves. Inevitably when one receives a shipment of an inexpensive 3D printer these days, it’s billed as able to support PLA, ABS, PETG and TPU. But in the box you will find only one thing.

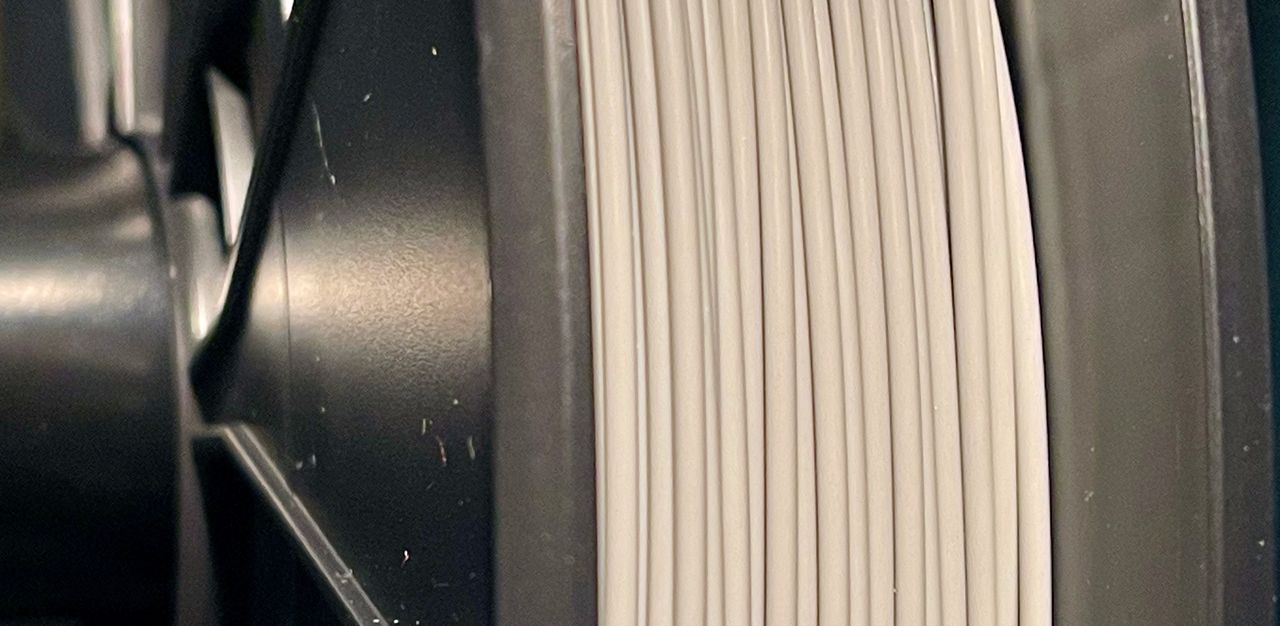

A small coil of PLA.

That’s the material almost each and every new 3D printer operator starts with. The challenge of 3D printing is significant for many, and having achieved success with their spool of PLA, the majority most likely won’t switch to another material unless forced to do so.

That’s why I believe PLA sales continue to rise. They will keep going until we start seeing 3D printer manufacturers include different startup materials with their machines.

Personally, I prefer PETG, as it just prints more easily than PLA in my experience, and it often looks better, too.

What are your thoughts on using PLA? Do you continue to use it? Why not try a different material?