I’ve given up on Simple Green as a resin 3D print solvent.

When I first set up my resin 3D printing workstation, I knew there were more components required than just the 3D printer. To complete a resin 3D print, it must be washed free of wet resin and then cured with extra UV light. There’s also a requirement for a variety of tools, resin bottle storage, PPE, paper towels, and a trash receptacle.

For washing 3D prints, the typical approach is to use IPA, usually 91% or better in purity. However, as this was my first setup, I was a bit nervous about having such a large container of flammable material present.

I looked around for alternative solvents, and one that was frequently mentioned was Simple Green. It’s a commonly available cleaning solvent that is sold everywhere. It’s also very green.

I topped up my wash reservoir with a couple of jugs of Simple Green and went to work on printing.

The Realities of Using Simple Green as a Solvent

As a solvent, it “sort of” worked. It did remove the wet resin that is always found on completed resin prints, but that wasn’t the end of the story.

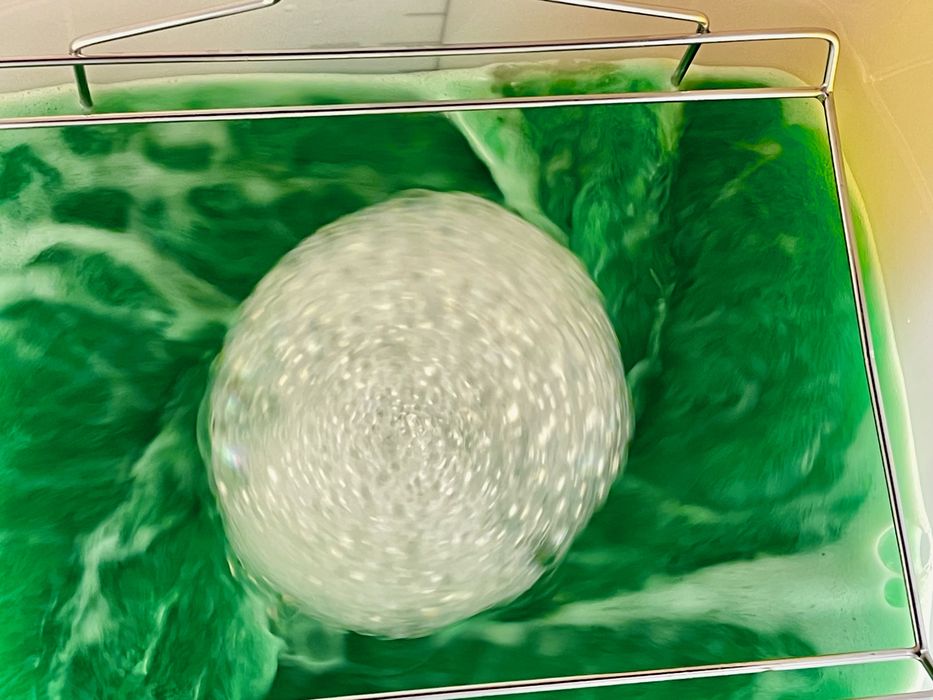

The solvent had a habit of foaming up while being agitated in my washer, which wasn’t fun. The foam would creep up on the top and sometimes come into contact with tools or handles.

I found that the prints that emerged from Simple Green still had a bit of a slimy surface, which is not at all desirable. Eventually, I had to set up a separate IPA bath to clear off the slime, defeating my original goal.

There was another bad effect from Simple Green: it has a very strong odor. This is because it’s actually for cleaning, where you want a nice “clean” smell after using it. However, I found this odor to be impregnated into the prints! They smelled like Simple Green afterward.

How did I eliminate the odor? Again, I ended up soaking the prints in a separate IPA bath. Usually, it would take several hours to be certain the smell was eliminated. These extra steps added significantly to my resin 3D printing workflow, and I was not happy.

If that wasn’t bad already, there was an even worse outcome encountered when disposing of the Simple Green.

The Challenge of Disposing Used Simple Green

Eventually, I resolved to switch the system over to proper IPA, and that’s straightforward, except for the step of disposing of the used Simple Green.

Let’s back up a bit: if you are disposing of “dirty” IPA, it’s very easy—just leave it outside in the sun in an open tub. The dissolved resin will gradually polymerize and sink to the bottom. First, it will be a sludge, and then over the course of a day or two, you will get solid. The IPA itself evaporates away, leaving a dry tub with some crusty polymer at the bottom that’s easily disposed of.

This process is not the same with IPA. I first found that the resin isn’t really dissolved in Simple Green. Instead, it clumps into blobs.

Laying out a tub of dirty Simple Green in the same way as above didn’t work nearly as well. Because the solvent is opaque, the sun’s UV rays didn’t penetrate deeply to cure the resin clumps. The Simple Green doesn’t evaporate very quickly, although it did slowly over the course of a week.

In the end, I was left with a green residue that had to be safely disposed of separately and some crusty bits fused to the bottom of my tubs. The process of removing the Simple Green took many days in a process far worse than with IPA.

Needless to say, I will not be using Simple Green again as my 3D printer resin solvent.