A tool manufacturer has leveraged 3D printing to make their product more attractive to buyers.

If you’re not familiar with Wiesemann 1893, you should be. It’s a brand of high-grade shop tools that focuses on the needs of makers. Currently they operate from Germany and the USA.

Their products include hammers, ratchets, axes, screwdrivers, wrenches, and even crowbars. Each tool type is offered in a variety of stylings that should match anyone’s specific needs. For example, there are 13 different types of hammers, ranging from an “Engineer’s Hammer” to “Roofing Hammer” to 1kg sledges.

Their products are of such quality that buyers use them over long periods. However, Wiesemann 1893 observed that many of their customers don’t use holders for their Wiesemann 1893 tools.

Their solution was to use 3D printing.

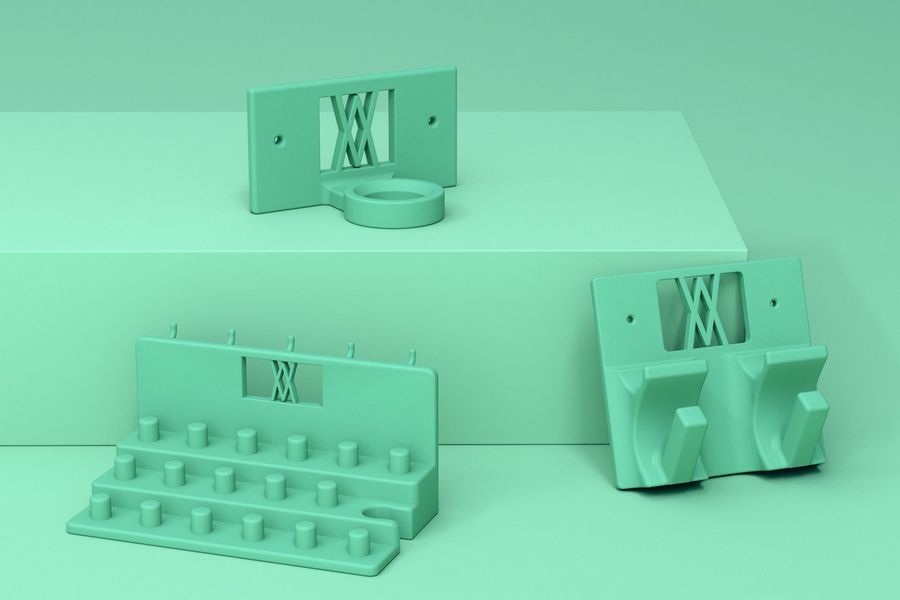

Wiesemann 1893 designed custom 3D printable holders for all of their tools, and placed these 3D models in their online store. Priced at €0.00, they are freely downloadable from their ENABLE 3D program.

The idea is for customers to 3D print the required holders for their Wiesemann 1893 tools and set them up in customers’ workshops.

Wiesemann 1893 explains (via Google Translate):

“With ENABLE 3D you get perfectly fitting holders for each of our tools. Instead of selling expensive accessories, you can get specially developed holders for your 3D printer here.

Whether developed by us or directly from the community – all ENABLE 3D holders are designed for additive manufacturing. Put an end to the chaos and bring order to your workshop.”

Wiesemann 1893 buyers are a tight community; they love their high-quality tools and often want to promote them. The company has directed some of that energy toward the ENABLE 3D program, where they permit holder designs to be produced by the community and then placed in the ENABLE 3D section of their online store.

This promotes more innovation in design as customers might come up with ideas not considered by the company, and also offers more choice for buyers.

Wiesemann 1893 promotes the ENABLE 3D program as a means to recycle waste plastic. The idea would be to chop up old plastic parts and 3D print them into the useful holders. They even published a video of one customer doing exactly this:

However, there’s many problems with this approach, as transforming recycled plastic into usable quality 3D printer filament is a very challenging business. You require specialized equipment and a reasonable supply of highly-consistent input thermoplastic, which is harder to obtain than you might think.

Once you have those, you then have to determine the optimum print parameters, which will use up some of the material supply.

While the idea of recycling plastic in this way is admirable, it is likely impractical for many Wiesemann 1893 customers.

The ENABLE 3D program has two effects:

First, the workshops will be a bit more tidy. While tools might have been laying on tables or hidden in boxes, the holders permit these tools to be organized in a visual manner on workshop walls.

Secondly, and perhaps more importantly for Wiesemann 1893, the visual display of the tools becomes a kind of subtle marketing approach. Visitors to Wiesemann 1893-equipped workshops will quickly notice the attractive tools displayed on nearby walls, whereas they may not have noticed them at all if stored in toolboxes.

I have little doubt that the ENABLE 3D program will enhance Wiesemann 1893’s tool sales, but I’m wondering whether other tool companies could offer similar programs, as Wiesemann 1893’s tool holders will typically not work for other tool brands.

Could we see a Black & Decker, Stanley or other tool maker offer a similar program? We already know that Stanley, at least, is deeply involved in 3D printing in various ways. A tool holder program could be another.

Via Wiesemann 1893 (Hat tip to Benjamin)