Dr. Andrei Neboian, Founder of Xioneer Systems, discusses the advantages and disadvantages of using various soluble support materials on different styles of 3D printers.

“I don’t care about multi-color, I just want soluble supports,” writes a 3D printer user in a forum on dual-material 3D printing.

This is part one of a two-part series. Part two is here.

Sure, a model of a four-colored amazon rainforest frog would look great in your 3D printed collection. But enough users would agree that the true potential of dual-head printers lies in their ability to print soluble supports rather than a palette of colors.

A quick search on Google reveals dozens of soluble support filaments on the market. Most of them are based on well-known water-soluble polymers PVA and BVOH. But there are also new contestants coming out such as VXL that provide superior performance to PVA.

But printing a support-material combination is not the same as printing two colors of the same filament. So, which dual extrusion 3D printer is up to the task?

In general, multi-material FFF technologies can be classified into five categories – each with its own pros and contras when it comes to printing soluble supports.

Depending on how often you print, what support material you use, and how much you are willing to invest, you might even find the perfect match for your needs.

The good news: you can get a decent 3D printer in any of these categories for under US$1000. So read on.

Mixer 3D Printers: Lowest Price-Tag But Probably Not the Best Choice for PVA

In 2014, the legendary 3D printer component manufacturer E3D-Online came out with its “Cyclops” hot-end. The name says it all: It is a hot-end with two inlets, but only one outlet: the “eye.”

This mystical creature takes two filaments in, melts them inside, and extrudes a single strand of mixed material. It’s great for mixing colors and creating stunning color gradients in your parts using just two filaments.

But can it also print supports?

The mixer hot-end acts as a Y-splitter – letting you extrude either support or model material from a single nozzle – without mixing them together. So yes, it can print supports too.

3D printers with a mixer hot-end like the Geeetech A10M sell from US$230. This price tag is really hard to beat when it comes to something as sophisticated as dual-material 3D printing.

Nozzle calibration on these machines is straightforward because they use only one nozzle. No need to fiddle with extruder offsets, which are notorious in systems with two separate nozzles. So with a device like A10M you could start churning your complex models with supports soon after unboxing.

But before you grab your credit card to order an A10M, you might want to keep learning about some of the drawbacks.

Mixer hot-ends require you to print a purge tower with every print job. It is a way to clean the nozzle before switching materials and avoid material bleed in your parts.

But getting the right amount to purge can be tricky. Purge too much and you needlessly waste precious filament. Purge too little, and the residues of support filament will contaminate your model affecting part stability and surface quality in the end.

But one way or another: mixer hot-ends will always produce waste.

Besides, using PVA with a mixer hot-end is a challenge on its own.

PVA and similar water-soluble materials are very sensitive to heat. If you leave them lingering for too long in a hot nozzle, they will degrade and turn into a crusty mess – clogging your extruder.

So, with mixer hot-ends, you want to keep PVA flowing through your nozzle as much as possible. This means shorten time window to print model materials. In practice, you will print only smaller models to avoid a clogged nozzle when using a mixer hot-end.

One trick is to use more temperature-stable support material such as VXL. But if you absolutely need to stick to PVA, the only remedy seems to use two separate nozzles – each with its own temperature control.

Traditional Dual-Extruders: Work With PVA But Are a Challenge to Calibrate

What’s the benefit of using two nozzles (for model and support materials respectively) versus a single alá “Cyclops” nozzle?

Using two nozzles lets you cool PVA inside your support nozzle while you print your model material with another nozzle. This helps prevent PVA from overheating and eventually clogging your extruder.

But this requires some tweaking to get it right.

However, PVA will need at least a 20°C-50°C temperature drop to keep the material from degrading too quickly. This leads to long heat-up times for every layer, adding to hours of unproductive time throughout the entire print job.

One solution is to use a temperature-stable support material such as VXL instead. The material does not degrade as quickly as PVA inside a hot-end saving you the need to cool down your support nozzles.

The two low-cost dual-printhead 3D printer models often found in reviews are the X-Pro from Qidi Technology and the Bibo Dual Extruder 3D Printer. These printers seem to be popular due to their low prices of US$482 and US$650 respectively.

A decent 3D printer model comes from Prusa with its i3 MK3S+, together with a dual head upgrade. This kit would burden your wallet with around €890 (US$1030). However, with the reputation of Prusa and its supportive community, this investment may pay itself off quickly.

But despite their advantages over mixer hot-ends, dual-printhead models do not always sell well. I once asked one of our resellers why.

The problem wasn’t the higher price. It was the complexity of getting these systems calibrated. This reseller required its users to undergo rigorous mandatory training to learn how to use dual-head machines (probably to save hours of support calls later on).

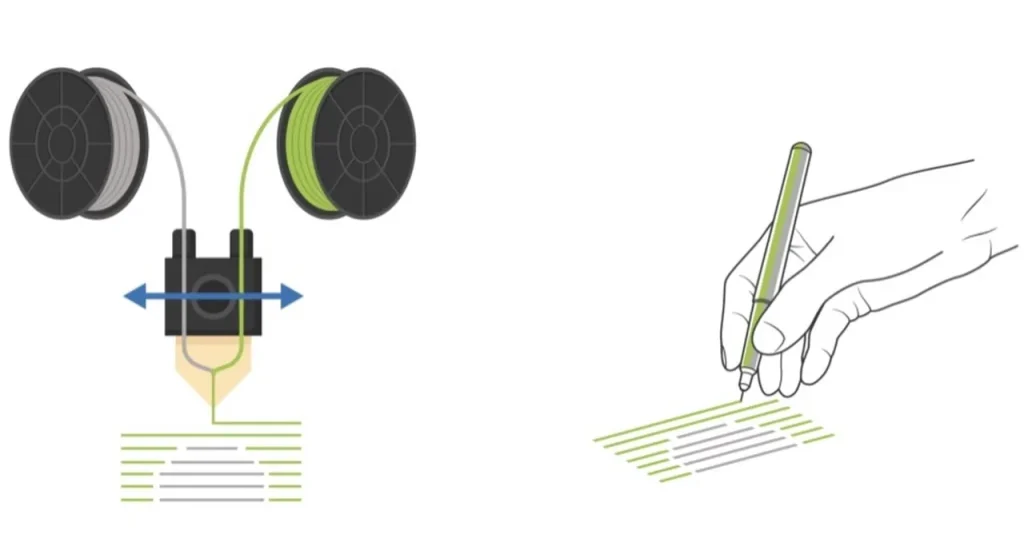

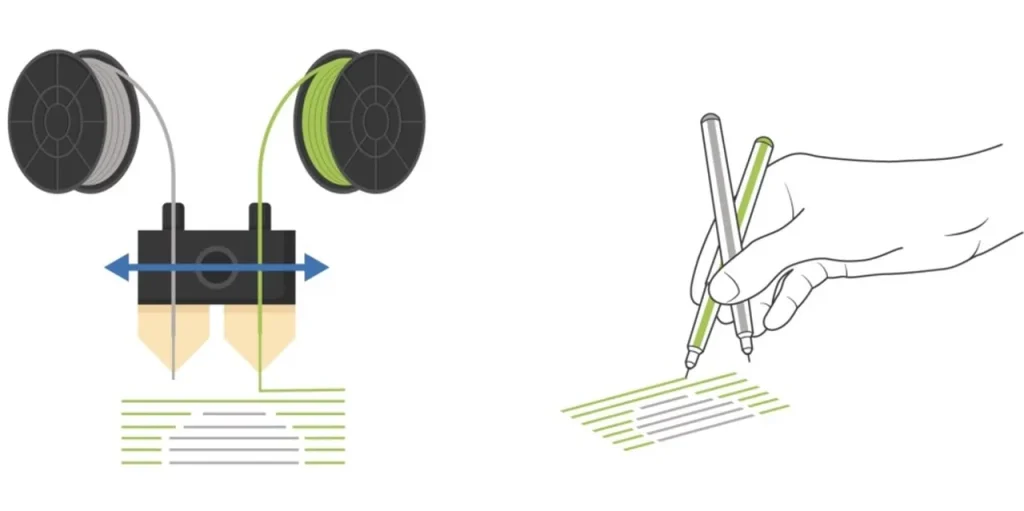

Imagine holding two pens in your hand and trying to write something with both of them at the same time. One of them will always try to lift up, while the other will be pushing too hard against the paper. It’s really tricky.

The same problem happens when printing with two nozzles mounted on a single print-head. If one is too low, it may kick your part off the build plate. If it is too far, the layers will not bond well.

So calibrating the height of two nozzles in a sub-millimeter range will take time and experience to get it right before every print job.

Actually, this problem was one of the reasons 3D printing companies came up with another solution: place both nozzles on separate print-heads: each with its own temperature and motion control.

This is part one of a two-part series. Part two is here.