Charles R. Goulding looks at a new book detailing the history of new aerospace companies that heavily use 3D printing.

Ashlee Vance’s new book “When the Heavens Went on Sale” provides a fascinating behind-the-scenes look at a new breed of Rocket pioneers.

Vance is known for his previous book about Elon Musk, another rocket pioneer. Vance explains how high-performance consumer electronics provide new reliable low-cost components that the established rocket manufacturers never utilized. Simpler low-cost rockets enable frequent launches that eject thousands of satellites into space.

These satellites are essentially disposable and can be easily replaced. This development is going to enable the 3.5 billion people that aren’t connected to the internet to become tech-enabled. The subtitle of the book is “The Misfits and Geniuses Racing to Put Space Within Reach.” Two of the best segments of the book cover Peter Beck of Rocket Labs and the history of Astra Rockets.

Peter Beck

Peter Beck of Rocket Labs is a self-taught Rocket enthusiast from New Zealand who has revolutionized the rocket industry with relentless energy and ambition. His story demonstrates that an entrepreneur with passion can maximize very limited resources and create a world-class product.

Beck’s success story is inspirational. Not only was Beck attempting to create a high-quality product with limited resources, but he was also doing so in an uncharted industry. Beck is a pioneer in a still-pioneering industry (commercial rockets).

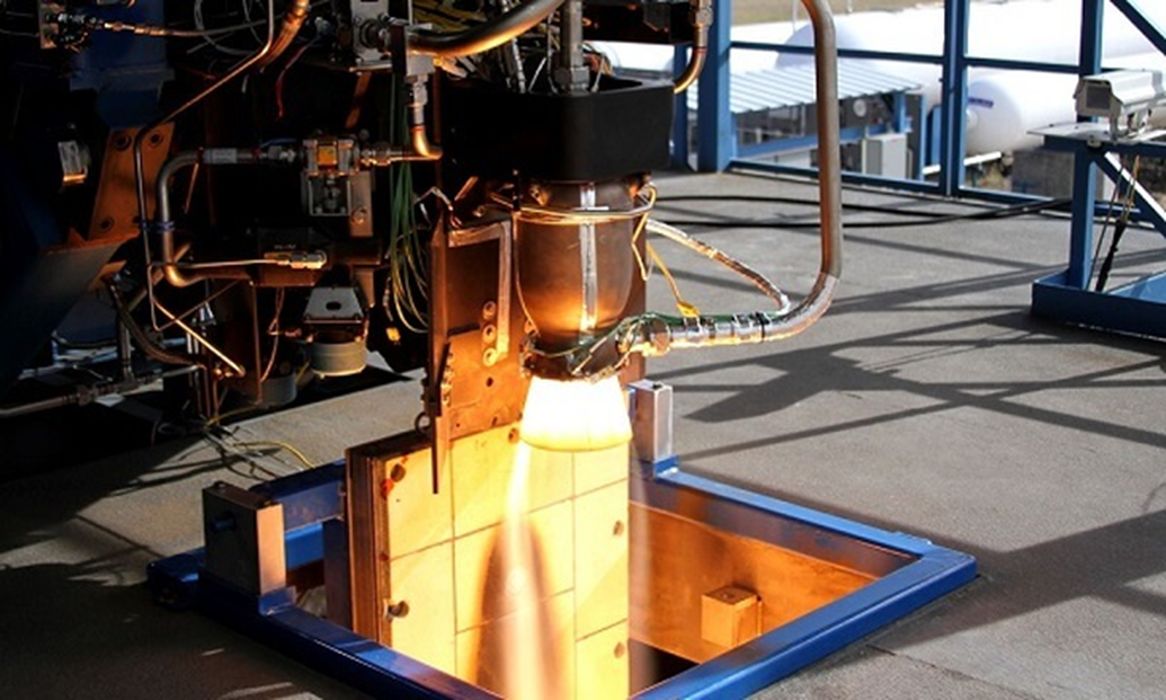

Rocket Lab’s Rutherford engine, used in CubeSats (small satellites), is the world’s first oxygen/hydrocarbon engine to incorporate 3D printing for all primary components. A unique electron beam melting 3D printer was used to create an engine that can deploy a satellite to a commercial orbit using less fuel than a flight from San Francisco to Los Angeles.

Astra

The Astra saga is fascinating because the company allowed Vance to become embedded in the company on a long-term basis. This enabled Vance to see firsthand the entire process from manufacturing through the prices of identifying a launch site, developing it, and executing the detailed launch process.

Vance’s detailed descriptions of failed and sub-optimal launches vividly portrayed the anguish and challenges related to the nascent industry.

Related Rocket News

The related rocket news is that some of major the assets of the recently bankrupt Virgin Orbit have just been sold piecemeal to multiple Rocket companies including a launch site, Rockets labs, for US$16.1M. Rocket Lab will also receive the company’s 3D printers and a specialty tank welding machine. Virgin Orbit then sold other assets to Launcher, a subsidiary of Vast Space, for US$2.7M, as well as the modified Boeing 747, “Cosmic Girl,” carrier aircraft to Stratolaunch for US$17M.

Although the demise of a company is never good news this may be a positive development overall since resource-challenged industry players can obtain industry-specific assets they can capitalize on.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The book was thoroughly engaging and a must-read for anyone interested in the commercialization of the rocket industry, a heavy user of additive manufacturing technology.