I’m reading one of MakerBot’s recent case studies, and had a thought about how the company has changed.

MakerBot began as a rough-and-tumble Brooklyn-based startup making a home 3D printer kit. Rudimentary as it looks in retrospect, it was revolutionary and its buzz kicked off the widespread use of the technology we see today.

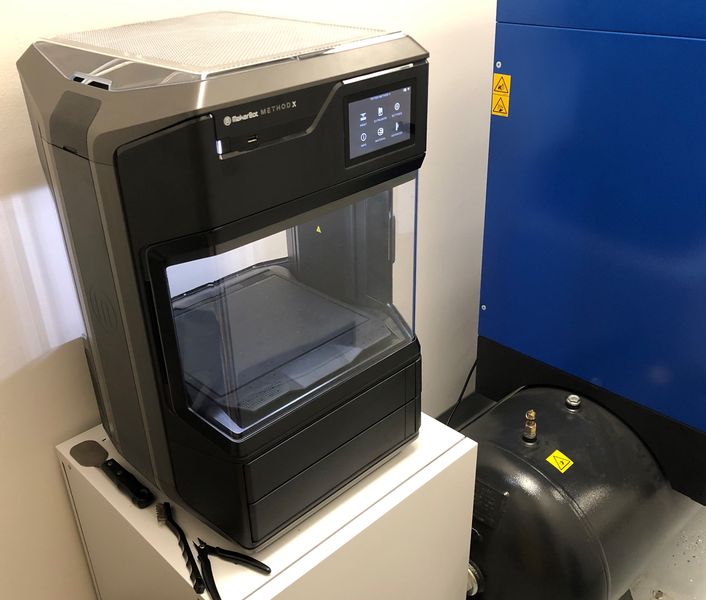

Since then they were acquired by Stratasys in 2013 and have made countless internal and external changes. Today they market an incredibly powerful professional desktop 3D printer, the METHOD. I’ve seen the amazing output this device can produce, and wish I had one myself.

That said, my positivity is totally overwhelmed by the negativity towards MakerBot that still exists in the 3D print community. There are many who felt MakerBot should have continued the path it began in 2009, and not shifted towards a professional audience as it did in the years after the Stratasys acquisition. Many were miffed by Stratasys’ patenting variations of community-contributed ideas that occurred during the transition, and still are disappointed.

Today MakerBot is completely, entirely different. Staff, management, products, markets and “methods” are all new.

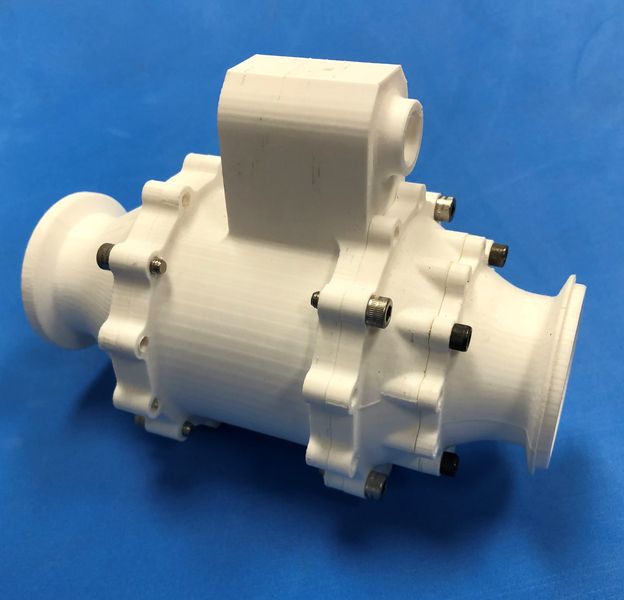

Let’s take a look at their most recent case study. It deals with one of their clients, Triton Space Technologies. The small Boston company designs and produces high pressure fluid system components, and is currently developing products that will be used by a client to go to the Moon in 2022.

Triton Space Technologies’ approach is to design the part and produce it on their own CNC systems. However, as we all know, CNC machining can be expensive and wasteful of material, so they’ve turned to using 3D printing to prototype their parts before committing to production. And as you might guess, they’re using MakerBot’s METHOD system to do so.

Here’s a video of Triton Space Technologies founder Luke Colby describing what he does with his MakerBot METHOD:

Colby says:

“We know what our design intent is, so when we print something, we know if the part is going to be useful. If we have to send it out to an external agency, the part might not necessarily be oriented in the direction that’s most useful to us. Now, if a design doesn’t come out quite right, or we want to make a change, we can do that ourselves very quickly. The reliability of the METHOD X means we can set a part to print overnight knowing it will be ready to use in the morning. Using the app, we can check on the progress of the print remotely. That is a really practical feature.”

That sounds all fine, and is increasingly the leading approach for product design with the advent of easily-accessible professional 3D printing options like MakerBot’s.

Then stepping back, I realized how massively different this scenario is from MakerBot’s original intent: this is not taking place in someone’s home or garage; Colby is definitely not a DIY maker; lunar rocketry is not a consumer application.

Everything, utterly everything, is different.

Colby and clients like him are quite satisfied with the products and service they get from MakerBot on their new products, and that seems to be the way the company will proceed in the future.

But MakerBot still holds that reputation among many, now based on products that no longer exist and a company that, let’s face it, effectively disappeared seven years ago. It’s gone.

I really wish MakerBot would change their name to finally and entirely disconnect themselves from that other company’s reputation. However, when I suggested it to MakerBot CEO Nadav Goshen, he wasn’t too receptive.

Via MakerBot