We have a small update from the folks at Glassomer.

The company launched in 2018, and we met them at their first public appearance in 2019. Recently we had another chat with their representatives to find out the latest updates.

You might recall that Glassomer is, as far as I know, the only producer of true glass 3D printer resin.

How can you 3D print true glass? Glassomer’s resin appears to be a clear fluid, but actually it’s made of 60% glass. The glass is extremely small particles measuring 50-100nm (that’s nanometers, not micrometers), rendering the 0.00005mm particles invisible to the eye.

The resin is 3D printed in a normal desktop-style resin 3D printer, and this produces a “green part”. This part is then post processed to remove the polymer binder, and then sintered to create a fully solid glass part.

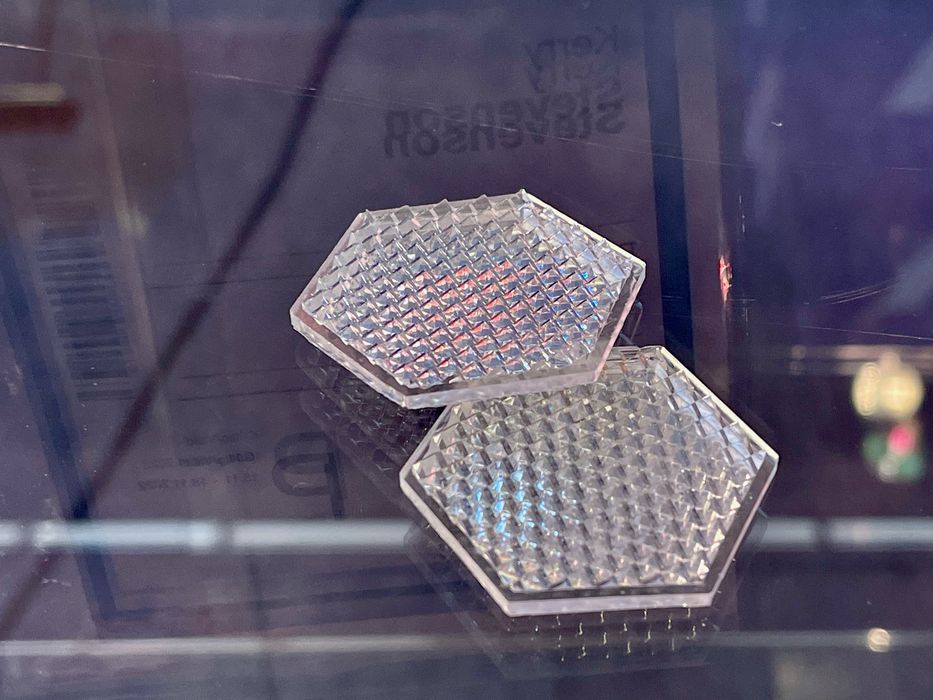

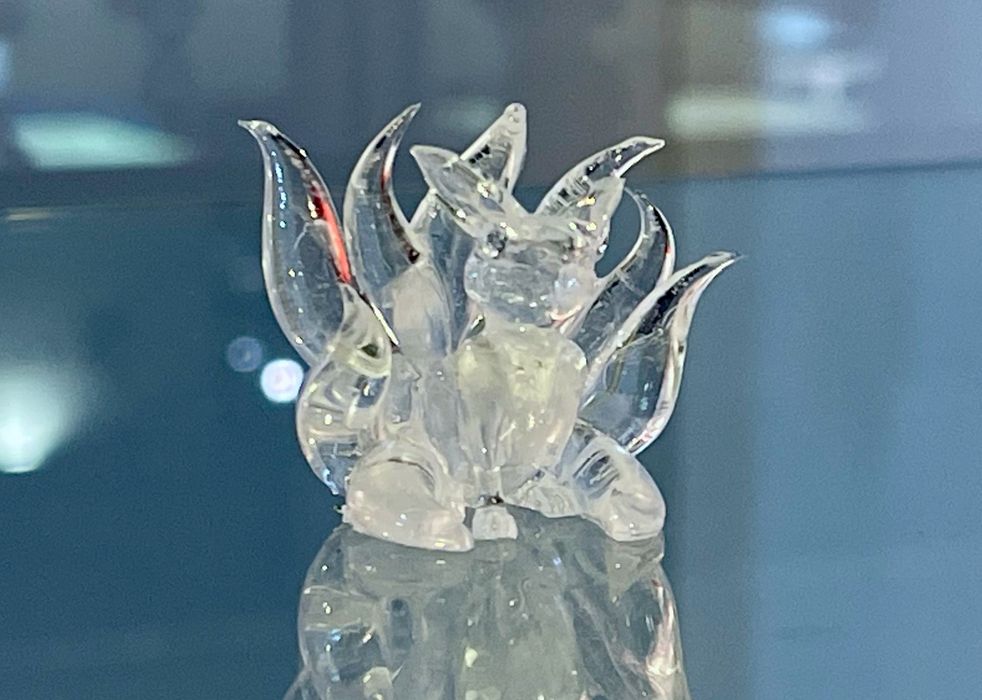

When I saw their prints in 2019 it was quite impressive: the parts were indeed glass and exhibited incredible detail that could only be produced on a 3D printer. However, they were relatively small and flat.

Over the past couple of years Glassomer techs have made some refinements to their material and process. This no doubt includes more sophisticated post processing thermal profiles.

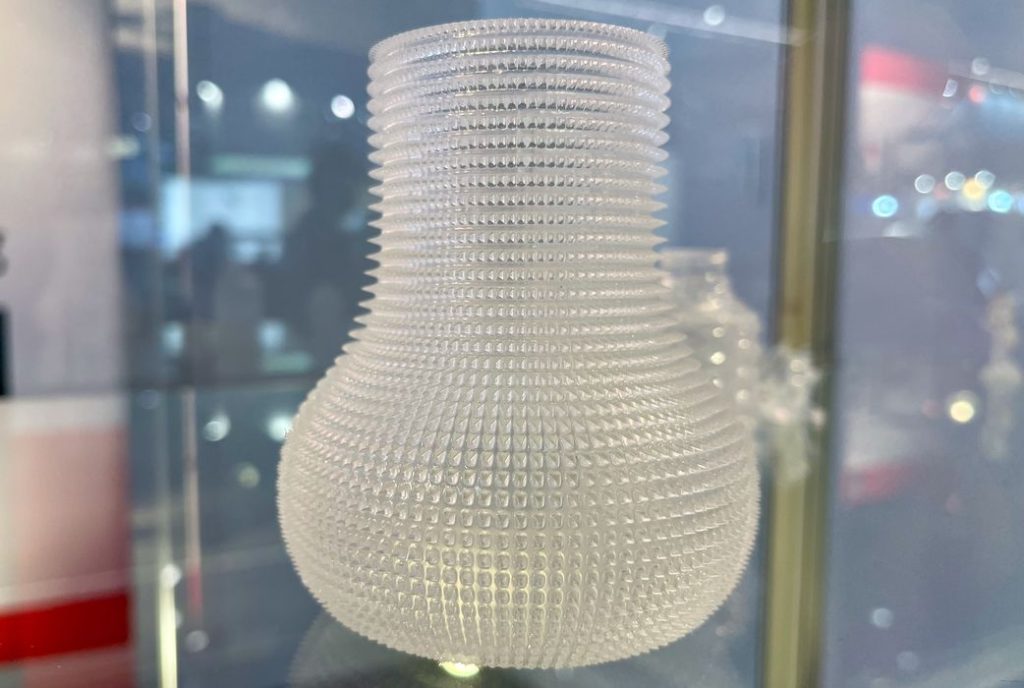

The changes allow the printing of larger-scale glass objects, and they’ve also implemented tuning to achieve higher resolution and quality on 3D prints made from the resin.

One important change is the addition of an extra step after printing to remove the visibility of layer lines. This produces very shiny and smooth surfaced glass objects, as you can see in the images.

These improvements could create even greater use of their resin to produce highly complex glass objects. Normal glass production methods are subject to a number of constraints that greatly limit the geometric possibilities, but 3D printed glass removes these barriers.

The question is whether industry knows how to apply this new glass technology, aside from the obvious optical uses. Many times I’ve seen new 3D print innovations appear, only to grow slowly because, while they are technically interesting, no one knows what to do with them. It could take some time for Glassomer and others to develop key applications for the technology, but that’s the lifecycle new inventions often follow.

If you’re interested in attempting to 3D print glass objects, you should contact Glassomer for further information. They do offer a free “sample box” of prints to show the possibilities with their unusual technology.

Via Glassomer