Zortrax released a beta version of their new 3D print management software, Z-Suite.

The Polish company is a well-known manufacturer of 3D printers using both filament and resin for professional and industrial use. The new Z-Suite, version 3.0.0, will replace the current 2.26 version after the beta testing period concludes.

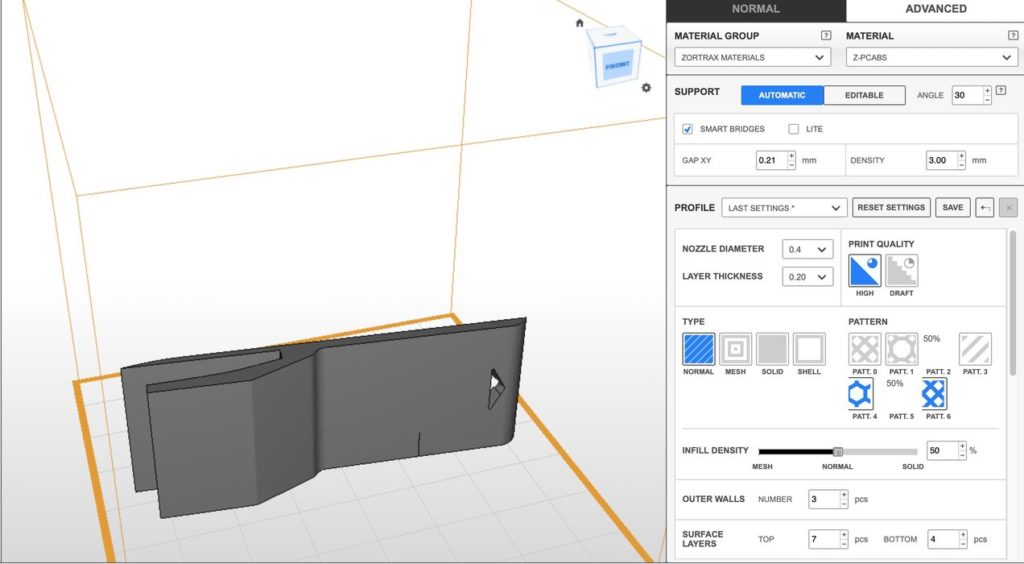

I’m not personally a Zortrax user, but I did take a look at Z-Suite 3.0.0 to see what’s new and how it compares to other contemporary 3D print management suites. Of course, Z-Suite is focused on Zortrax’s complement of 3D printers, which now numbers six different models.

Z-Suite is designed to provide a full-function experience for those operating Zortrax equipment. It includes not only the ability to prepare 3D models for printing, but also to connect with devices over the network to launch and control jobs. From what I can see, it supports only Zortrax 3D printers and Zortrax materials, but apparently it can also control farms of Zortrax equipment if required.

This is a case of a closed system providing a consistent experience for operators: if the hardware and software are known, then the 3D print job parameters can be finely tuned in advance to ensure job success. This is a value highly desired by some operations, but not by others, who might want to use alternate materials or achieve different printing objectives.

It also allows Zortrax to easily implement any specialized features they’ve invented for their equipment not found in other systems.

Moving on to the new features in 3.0.0, Zortrax lists several, including:

- New infill patterns

- Outer walls option

- Offset inner contours

- New Seam modes

- Thin wall quality

- Print too thin wall option

- Slanted surface quality

- Top surface stability

- Improved bonding

- Shell mode supports

- Concentric infill mode when solid

- Display single layer in preview

One that is highlighted by Zortrax is something they call “Multiple Contours”. This sounded interesting to me, so I took a closer look. It seems to be the ability to change the number of perimeter walls on a print, which can greatly increase the strength of the part. That’s a good feature, but somehow doesn’t seem particularly revolutionary: haven’t most slicers been able to adjust the perimeters for some time? I have similar feelings about the remainder of these new features. They’re new to Z-Suite, but not necessarily new to the industry.

I’m sure you’ll agree these are all good improvements to have, but what’s going on here?

Most 3D printer operators now make use of three main job preparation platforms: PrusaSlicer, Ultimaker Cura and Simplify3D. These three have very comprehensive capabilities, and at least two of them have been frequently updated with new and experimental features. The new Z-Suite features seem to be a bit of a catch up in some ways to these alternate slicing tools.

But that is what happens when a closed system is created: Zortrax supplies the hardware, materials and also the software, which in this case is Z-Suite. And keeping that software’s features to match other slicing systems is a really hard thing to do.

It’s particularly challenging when there’s tools like Ultimaker Cura and PrusaSlicer, both of which have rather large communities continuously contributing new advanced software components. Zortrax would have a difficult time matching all their features.

But it doesn’t really matter, because if you’re in the Zortrax universe, Z-Suite is what you’re using because that’s the way the system is designed. For some that’s a good scenario: there’s relatively little to worry about, just use the hardware, materials and software and it will work.

On the other hand, one wonders what Zortrax is missing by not aligning with other software tools.

Via Zortrax