I spoke with Nick Stratton, the fellow behind Hotends.com about their recent activities.

Stratton, it turns out, was not the founder of Hotends.com. There’s a bit of tale of how he became involved.

Stratton was a data recovery engineer based in Madison, Wisconsin for many years, but was also a 3D print enthusiast in his off hours. He actually ran a small 3D print farm, which just happened to make use of the J-Head hot end from the original Hotends.com, which has been in operation since 2011. Through the farm experience, Stratton gained a great deal of knowledge and experience with FFF 3D printing technologies.

Stratton learned that the original owner of hotends.com intended on shutting down the company, as the owner was transitioning to a new role. This didn’t sit well with Stratton, who quite liked the J-Head hot end used in his print farm. Stratton told me, “I did not want the J-Head brand to die.”

After some discussion with the original owner, it was decided that Stratton would acquire the company outright, which occurred in March of 2018.

Since then Stratton has been run off his feet building the business back up and maintaining existing products with his core group of clients. It’s been so much work that Stratton was rarely seen in the industry. Stratton said:

“I have been quite a phantom during that time.”

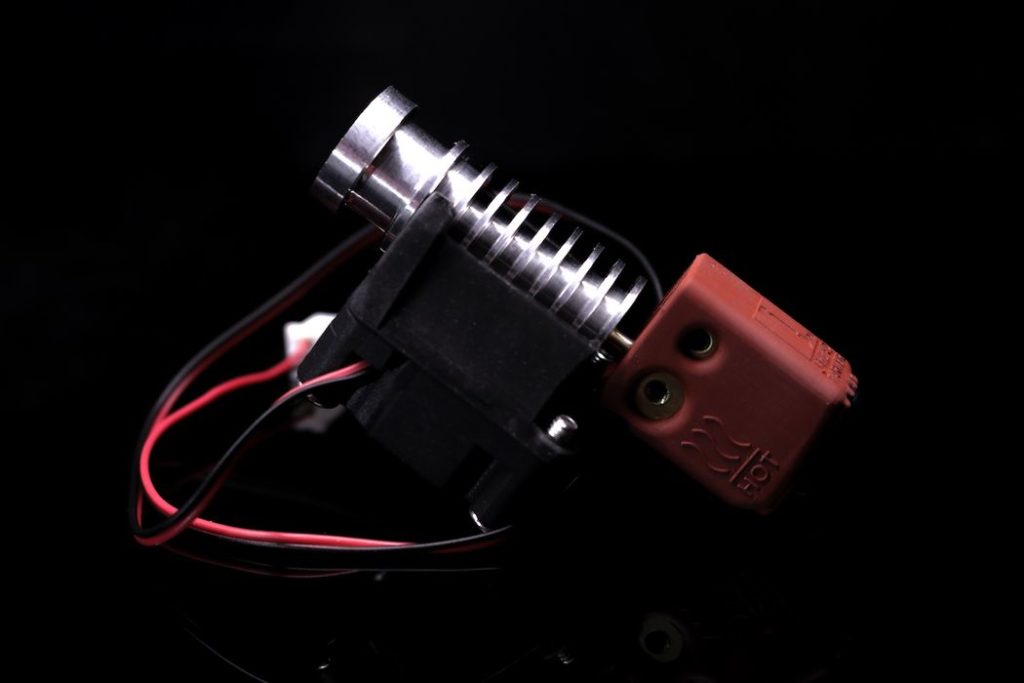

During that period Stratton was able to develop the first all-metal version of the J-Head, the HiFlow. More recently the company has produced the J-Head Farmer, targeted at those operating 3D print farms. According to Stratton, the J-Head Farmer is the “culmination of everything I learned producing the HiFlow”.

The key feature is that it can be disassembled while still installed on the 3D printer. This is quite different from most hot ends that require major surgery to extract when repairs are needed. That’s critical for a farm, where much of the manual labor is spent doing repairs.

However, this year Stratton has managed to position the company for expansion and scale up. He’s apparently made arrangements with suppliers and production partners for a full ramp up.

Stratton has also expanded the product catalog at Hotends.com to include a variety of other specialty parts for 3D printers. One of the most interesting is the “Bowden Aglet”.

If you’re not familiar, an “aglet” is that hard piece on the end of your shoelaces. The Bowden Aglet does something similar for Bowden tubes. There’s a special connector on each end, and the intent is to replace the PTC fittings on Bowden setups.

Why do this? It’s to eliminate the scourge of Bowden 3D printers: stringing. Bowden setups are notorious for retraction issues, which are required when the toolhead moves between extrusions. If not sufficiently retracted, plastic will dribble out the nozzle and cause stringing. The usual solution is to amp up the retraction settings, but that causes other quality issues in the print.

The other issue that frequently occurs in Bowden setups is print failures when the PTC fittings fail and the Bowden tube comes loose. This is particularly bad when it occurs towards the end of a long print job.

These are the reasons many people try to avoid Bowden 3D printers.

The Bowden Aglet solves this by eliminating any movement of the PTFE tube during retractions. Each end of the Bowden Aglet is tightly fixed in place, leaving no room for tube movement. Thus, as Stratton says, there is “no backlash”. The key to the Aglet is the use of fittings designed for this type of motion, rather than the usual connectors that expect constant motion.

Stratton explained the company’s strategy these days is to work on direct sales to 3D printer manufacturers looking to include the J-Head and other components in their equipment. In addition, the company’s website does sell units to individuals. However, Stratton indicated he has been negotiating with several resellers, so we may see more J-Head components appear elsewhere.

If you’re interested in an alternative hot end, or the intriguing Bowden Aglet, you might want to check out Hotends.com.

Via Hotends.com