The eternal question of those new to 3D printing is “what kind of 3D printer should I get?”

There are plenty of answers, but actually there are more questions to be asked first.

It’s all about intent. You see, it turns out that there are many different kinds of 3D printers, and each type does something different. What would be an ideal application for one 3D printer might be terrible for another type of 3D printer.

In other words, you must choose the right tool for the job. You can’t use a screwdriver to hammer in a nail — although some do try in the 3D print world.

People new to 3D printing don’t realize there are indeed very different types of 3D printers on the market. FFF devices are very different from resin 3D printers, and there are powder devices, too. It’s even possible to do rough metal 3D printing at low cost with the right materials and equipment.

While I can’t read your mind to figure out your own intent for using a 3D printer, I can do something you can map your needs into. Below are a series of “personas” and a recommendation for a type of 3D printer for each. Find the persona that best matches your situation and you’ll get a good option to proceed.

I’m a Parent Buying For a Child

There are actually few options here, as the major feature required would be ease of use (which basically no 3D printers provide, in spite of their advertising). Other features might be a locking door to prevent fingers from getting scorched, and an air filtration system.

The best bet here is to acquire an “adult” inexpensive FFF 3D printer and supervise the child when building and operating it. Don’t even think of using a resin 3D printer, as the safety concerns about resin toxicity are difficult enough to follow as adults, let alone children.

I’m a Techie-type Hobbyist

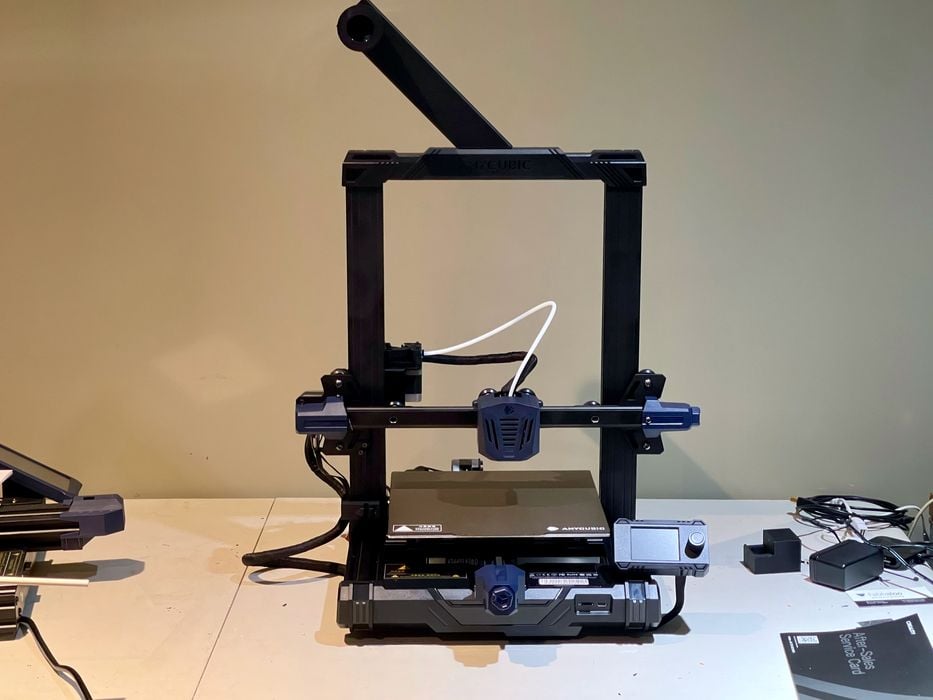

There are plenty of options here, and depending on the operator’s technical skills, different levels of machine. For those seeking a high-speed, high-performance FFF device, the Voron project can provide kits for assembly that are well-regarded. For those not so ambitious, the Anycubic Kobra Go is a very good device that requires an easy assembly. Another option is the Prusa MK3S+ kit, which has outstandingly easy-to-follow online instructions.

I’m a Non-Techie Hobbyist

Here there may be the most options available, as there are tons of pre-assembled machines ready for purchase at a variety of price points. While some are literally ready-to-go right out of the box, some require minor assembly as they were split apart to simplify shipping. Don’t be afraid of these “kits”, as they really require only a few minutes to put together.

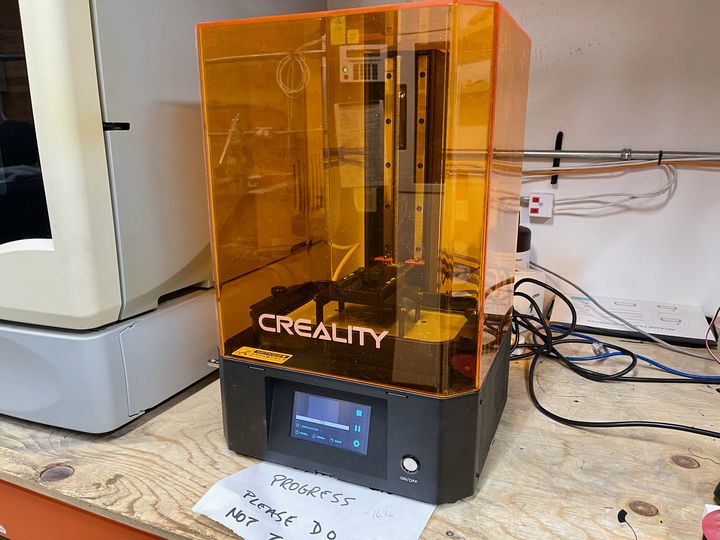

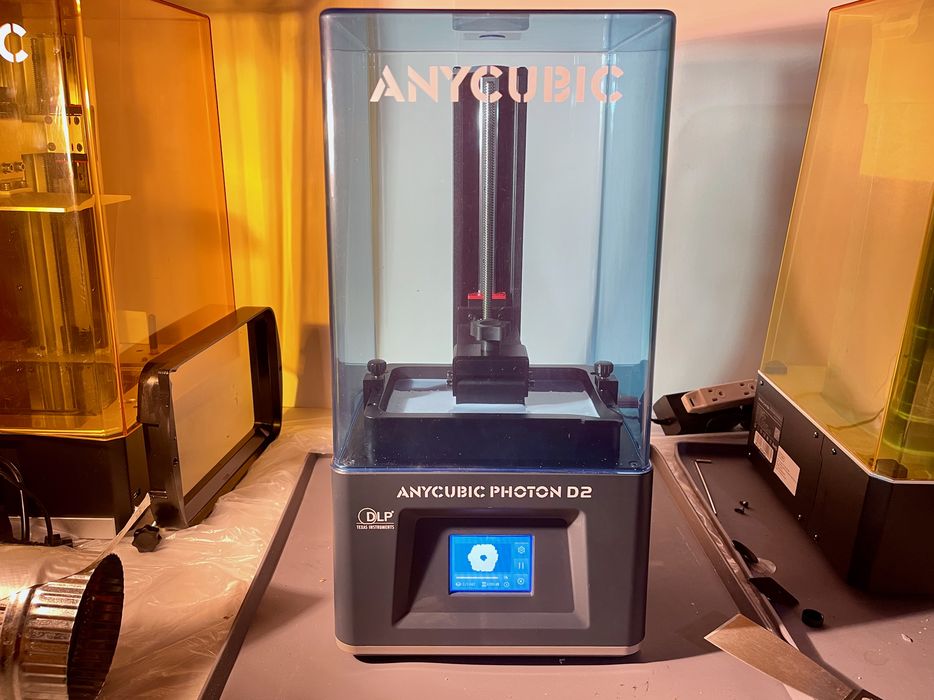

I Want To Print DND Figurines

For this application you really need to use a resin 3D printer that can produce high resolution 3D prints. Fortunately there are many now available from several vendors, including Elegoo, Anycubic, Phrozen, Creality and others. The pricing of these machines has been dropping notably in recent years, dipping as low as US$145 recently.

However, there is a caution: resin 3D printing uses expensive, toxic resin. To safely operate these devices you must have an actively ventilated room where fumes are removed. You must also use personal protective equipment like safety glasses and nitrile gloves, and follow rigid procedures. If you don’t you risk having a permanent toxic reaction to resins.

I Want To 3D Print Jewelry

Again resin 3D printers are required for this application due to their ability to produce high resolution parts. There are two approaches: make plastic jewelry or metal jewelry.

For plastic jewelry, simply print the designs and finish them. You’ll likely have to carefully choose the resin color.

The procedure for making metal jewelry is different. You first 3D print the object in a castable resin. The completed print is placed in plaster, dried and then fired to melt and evaporate the plastic, leaving a void into which molten metal is poured.

As you might imagine, this requires equipment beyond the printer and resin, specifically you’ll need a sintering furnace and appropriate tools. But if you’ve made jewelry previously, maybe you already have those items.

I Want To 3D Print Plastic Mechanical Parts

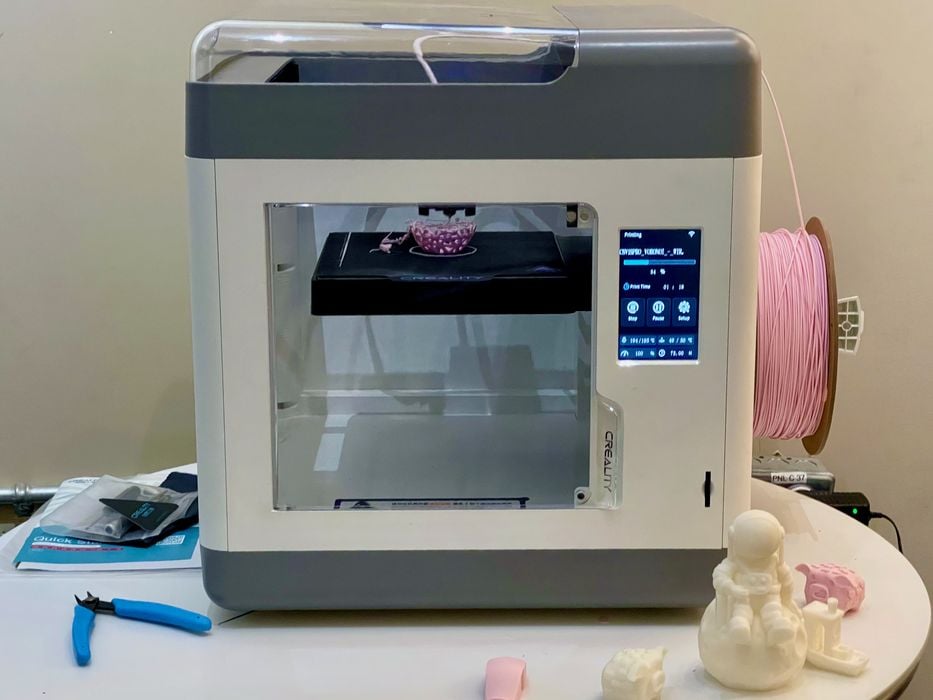

While this might appear to be quite possible with even the least expensive FFF 3D printers, better parts are created with 3D printers that can use engineering materials. PLA, commonly used in most devices, gets soft at only 50-60C, making it unsuitable for many applications.

Instead you’ll have to get yourself a 3D printer that’s capable of printing with engineering materials like nylon, ABS, ASA and similar materials. Basically you need a 3D printer with a hot end that can reach 260C, or even better 300C. Another keyword to look for is “all metal hot end”. The non-metal hot ends include PTFE material that can vaporize into toxic gas above 230C, so you don’t want that equipment.

The best quality prints will be found with 3D printers that include an enclosure to capture heat and keep the print at nominal temperatures throughput the job.

Unfortunately, this type of device is a bit more expensive than the low-cost FFF 3D printers you may have seen, so be prepared to spend a bit more.

I Want to 3D Print Metal Parts

Industrial metal 3D printers cost six or seven figures, plus a building to house them at even more cost. More than likely this is not the approach you’d like.

However, there are methods to 3D print rough metal parts using inexpensive FFF 3D printers. Beyond the casting method mentioned above, it’s possible to purchase “metal filaments”. These are basically normal 3D printer filaments, but with a high ratio of added metal powder. The prints are made in about the same way as a plastic print, but the magic is in post processing.

The prints are placed in a sintering furnace (you have one, right?) and the plastic portions are burned off, leaving the metal powder. This is then sintered at a higher temperature to fuse the particles together.

For this approach you’ll need a FFF 3D printer equipped with a hardened nozzle to handle the rough metal filament, and a sintering furnace. Note that the metal filaments can be quite expensive and are far denser than plastic: 1kg of metal filament isn’t that much material. BASF’s metal filament seems to be the most frequently used, but there are others, such as Virtual Foundry’s.

I’m a Teacher and Need a 3D Printer For Class

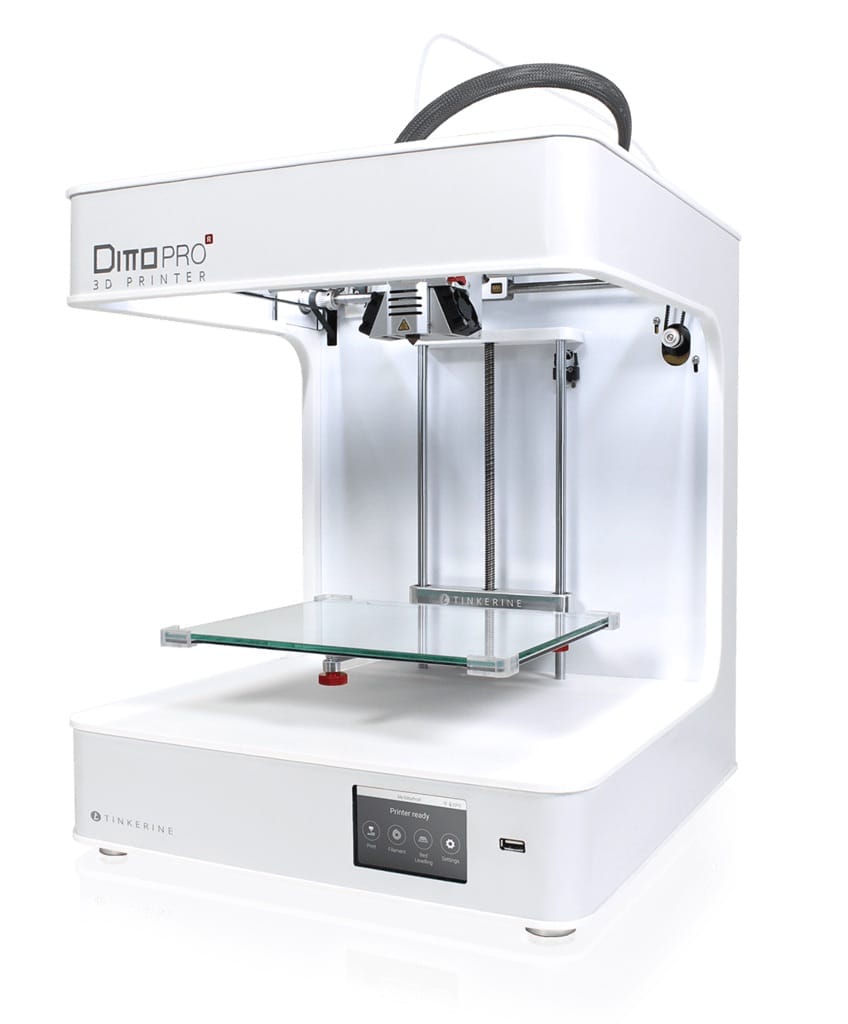

In this situation you shouldn’t really care too much about the 3D printer itself. Instead focus on the associated classroom materials, which are necessary to easily get started teaching 3D printing to students. Without this material, the educator must develop the complex curriculum on their own. The good news is that several providers have comprehensive offerings in this area. Look at MakerBot, Tinkerine and Afinia for possible options.

I’m a Professional and Need a Machine for the Office

While the answer here depends somewhat on the specific needs, there are some considerations for office use.

An office machine tends to have somewhat casual users that intermittently use the equipment. This could cause challenges with resin 3D printers, which require rigorous safety procedures that might be forgotten by casual operators.

Other considerations include noise. Some 3D printers can be quite loud, although advancements in stepper motor drivers have lowered the noise levels of some equipment. Another consideration is air quality: some machines with enclosures include air purification systems that eliminate odors and increase safety (note — not all enclosed 3D printers have these, please check every option.)

Finally, shared equipment may require job tracking to understand who has been using the equipment and material. Many low-cost 3D printers have no mechanism to provide for this, and therefore many offices opt for more expensive equipment that includes job logging.