There are now many sources of “tough PLA”, but what is this mysterious material and why is it gaining popularity?

I saw an announcement from filament provider Filamentive, who recently launched their version, called “PLA Tough”. It’s said to be an “industrial-grade material” that offers added strength, apparently increasing the impact resistance by a massive 750%.

That’s much the same story for other sources that also provide “tough” PLA material options.

There’s a bit of history to go through to understand how we arrived at a Tough PLA world.

ABS, The First 3D Printer Material

The original desktop 3D printers first produced around a dozen years ago did not use PLA. Instead they used ABS. This was because at the time no one actually made 3D printer filament. If a customer bought a 3D printer, they must have a source for materials, and someone thought up the idea of using “ABS welding wire” as the material. This item was commonly available in hardware supply outlets everywhere, providing an instant source of materials for buyers.

That part worked, but ABS had problems, particularly on the incredibly rudimentary machines of the day. Imagine, for example, attempting to 3D print ABS on an unheated acrylic print plate covered in blue painter’s tape with an open-format 3D printer.

Sounds ridiculous now, and it actually was then, too. ABS has significant shrinkage when it cools, and this, without thermal aids, caused massive warping of almost every 3D print. I know this because it happened to me.

Introduction of PLA

Then something interesting happened: PLA was introduced.

It was a revelation, and dramatically sped up adoption of desktop 3D printers because it was vastly simpler to 3D print. Printed at a much lower temperature meant the thermal gradient was smaller and thus less warping occurred. It was then possible to 3D print smaller objects on unheated surfaces without too much trouble.

But PLA’s benefits hid two important issues.

First, the lower softening temperature meant that PLA objects would suffer in high-temperature environments. A smartphone holder for a car, for example, might sag in the summer heat, as temperatures inside the vehicle on a summer day might high 50-60C.

The second problem is brittleness. PLA objects are quite hard, and this means that if you were to drop them, they might crack. Actually, they’ll probably crack, as I’ve experienced all too often.

ABS didn’t have that problem; it has a bit of “give”, meaning it can take an impact and not shatter. This property drew those building parts requiring impact strength back to using ABS, and that interest led to today’s heated print surfaces and sometimes heated chambers, where ABS can be 3D printed more or less reliably.

However, all that heat treatment is expensive, particularly if you are heating a chamber. That’s not something everyone can afford, and that left out the “PLA-only” devices from producing impact-resistant parts.

Introduction of Tough PLA Materials

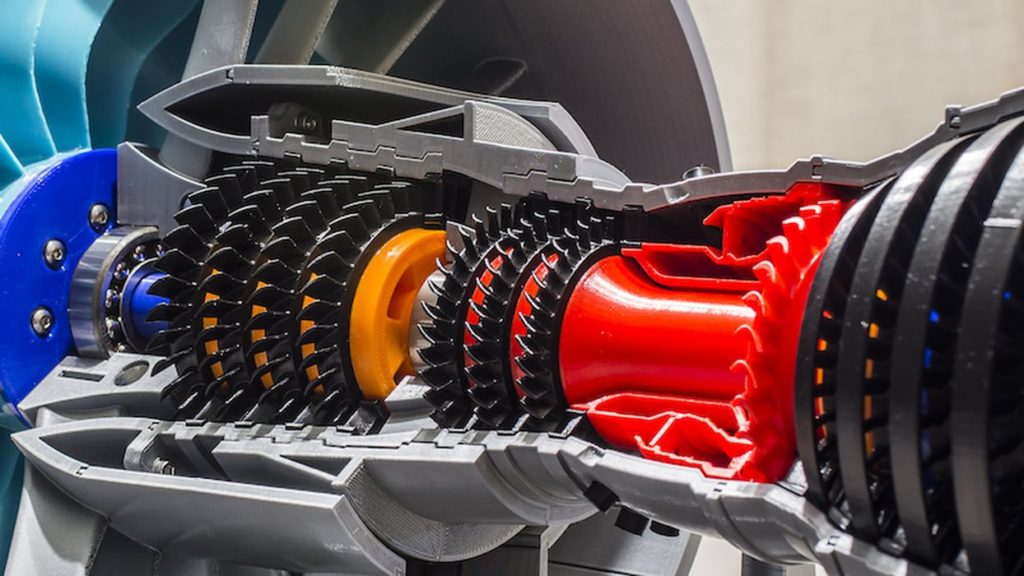

Then a few years ago we began to see the emergence of “Tough PLA” or similarly named materials. These are essentially PLA, but with additives that increase the impact strength. In other words, you could 3D print impact-resistant parts on a PLA-style device.

That’s an attractive proposition for many who build mechanical parts, as they can be made on inexpensive equipment.

But there’s still one catch: tough PLA still has mostly the same thermal properties as regular PLA. While your new tough PLA automobile smartphone holder won’t shatter if you drop it, it will still sag if left in the heat.

Don’t get me wrong here; tough PLA is a very useful material — just don’t think it is a complete replacement for ABS. Always choose the right material for the job.

Via Filamentive