Water-washable 3D printer resin is increasing in availability, but what are the real advantages of using it?

Resin 3D printing is becoming quite popular, in spite of the challenges of using the technology. It involves much more safety concerns than FFF 3D printing, and requires additional equipment and supplies.

It’s all about the resin. Photopolymer resin is a specially designed fluid that can solidify when exposed to certain frequencies of UV light, and that’s the secret sauce for resin 3D printers.

The problem is that the photoinitiators in these resins is almost always toxic. This means resin 3D printer operators must use personal protective gear, such as nitrile gloves, safety glasses, etc., when handling resin and the equipment.

It’s quite an ordeal to properly use a resin 3D printer, as you must have a highly disciplined process to handle the printer, resin and model. If you don’t, you’ll risk having a workstation coated in toxic, sticky resin.

One of the steps involved in the resin 3D printing process is cleaning. Typically this is done with an isopropyl alcohol bath, which dissolves the stray wet resin that coats the prints when they emerge from the 3D printer.

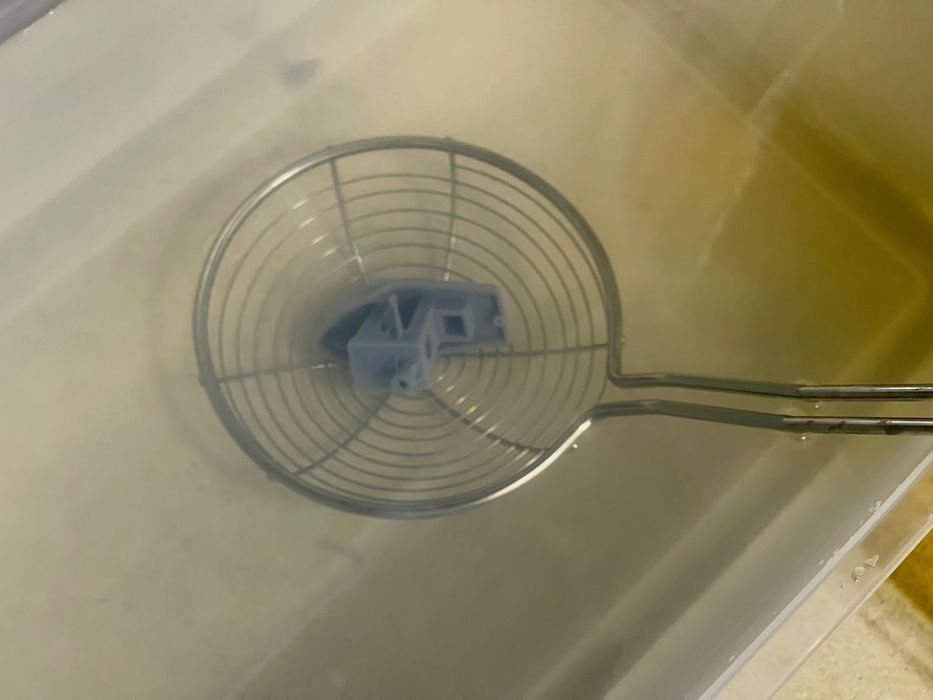

Many resin 3D printer manufacturers now also produce “wash and cure” machines to handle the IPA bath and subsequent extra UV exposure to harden the model. The wash station will include a tub of IPA into which the print is placed for cleaning.

Resin 3D printer operators will have to acquire a quantity of IPA for use in these wash stations.

IPA is a somewhat nasty substance. It is flammable and emits a very strong odor. Some don’t like the idea of having a large tub of flammable liquid sitting around.

Enter water washable 3D printer resins. These are resins that are pretty much the same as regular resins when printing, but can be dissolved by water.

The implication is that instead of filling up the wash station with IPA, plain water can be used instead. Initially, it would seem this is a good solution that could be safer.

I think water washable resins are indeed safer, but I am not convinced they are particularly advantageous over regular resins.

As I see it, there are only two advantages to water washable resins:

- The cost of water is less than IPA

- Water can’t catch on fire

Everything else in the washing process is essentially the same: the resin is still toxic, the water becomes contaminated with the toxic resin, and the water must be safely disposed of in the same way contaminated IPA must be done.

Since you’re using water, there is a temptation to treat it just like you do when cleaning other items, and you should NOT do that. You can’t pour the contaminated toxic water down the drain, just like you can’t pour contaminated IPA down the drain.

After using some water washable resin, it seems to me that the process of using water is effectively the same as using IPA. It just doesn’t smell as much. You have to use the same safe handling procedures as IPA. You’re just using water instead of IPA; everything else is the same.

As for the price of water vs. IPA, there really isn’t that much difference: large quantities of IPA are easily affordable by anyone.

Since I already have to have an IPA wash station for existing resins, I see no advantage in setting up a second wash station for water washable resins; in fact, that could cost more if I have to acquire secondary wash units.

For now I will avoid water washable resins, as I see little advantage in using them, and the prospect of additional cost and table space.

Is your experience with water washable resins different? Please let us know in the comments.