Novice 3D printer operators often wonder, “what is the PLA that I am printing?”

That’s a good question, and there’s an easy answer. PLA is simply (C3H4O2)n.

Sorry, I couldn’t resist. That’s the base chemical formula for PLA, which stands for “Polylactic Acid”.

PLA is a thermoplastic polyester material, which means that it can be softened by heating, and when cooled it resumes its former solid state. This is the key property that allows it be used in FFF 3D printers: the filament is heated until soft, then deposited layer by layer to form a solid print as the PLA cools.

PLA in 3D Printing

You might be wondering why PLA is so popular in the 3D printing world. It turns out there is a bit of a history to this material.

When 3D printing was invented in the 1980s, the processes were protected under patents for many years. During that period, the patent holders made most of their money by requiring use of their proprietary materials only. This meant there really wasn’t any general market or providers of 3D printing materials until much later.

In the 2008 period these patents began to expire, and that enabled the launch of numerous inexpensive FFF 3D printer manufacturers. These companies used basically the same technology as the patents had described, but did so legally as the patents had expired.

But there was still no suppliers of 3D print material. In a desperate move to ensure their primitive desktop 3D printers would have something to print with, they were designed to use a very commonly found material: ABS welding wire. This material was found everywhere, and could be made to work in desktop 3D printers.

But just barely. It turns out that ABS is a rather terrible material to 3D print because it tends to warp after printing. For a time, desktop 3D printing was a horror because most prints failed for this reason. And attempting a large 3D print? Forget it.

Then someone thought to use a different material: PLA. This was introduced because unlike ABS, PLA has a far lower tendency to warp, and it required lower temperatures to soften. Even better, it bonded quite well between layers, making prints relatively strong.

Once this was identified multiple parties launched PLA filament manufacturing lines, and the rest is history. Today virtually all desktop FFF 3D printers use PLA as their prime material.

Advantages of PLA in 3D Printing

Aside from the printing characteristics, PLA has some other interesting aspects.

Unlike most of the other thermoplastics, PLA is made from organic material. In other words, it doesn’t require oil. Instead it’s usually made from corn or similar crops. These are fermented and then exposed to high heat and catalysts to form PLA.

Being a substance NOT from oil is an increasingly desirable property.

Because PLA is made from organic material, there is a natural assumption that it is recyclable and biodegradable.

It is in fact quite recyclable, in theory. Because it’s a thermoplastic you can literally chop up a piece of PLA, heat it to a softened state, and re-extrude it to make new filament.

I say in theory because this can be impractical. Today’s PLA materials are always different colors, and often there are some additives that slightly alter the print properties. There are also PLA mixes that include fibers (glass, carbon fiber, etc) for strength. What all this means is that a given pile of PLA scraps is likely a dog’s breakfast of differing chemistries. This makes the re-extrusion a Frankenstein filament that can’t be predictably used.

PLA Biodegradable?

But what about biodegradability? Surely PLA, made from corn, can biodegrade?

Well, this is one of the biggest myths of PLA. It turns out that you can break down PLA, but it requires very special industrial treatment using extremely high heat and pressure. There are very few recycling centers in the world that are set up to do this. In other words, PLA is a long term polluter.

Experiments have been done to see whether PLA objects will degrade if exposed to water long term. Unfortunately, the experiments showed that the objects showed absolutely no degradation after 3.5 years in the jars. Similar experiments involving burying PLA objects yielded the same results

Regardless of the eco-friendliness of PLA, it remains the number one material for FFF 3D printing today.

Types of PLA 3D Printer Filament

You can obtain 1kg PLA spools for around US$20 each these days, and the selection of colors is vast and growing. In the past there were many options for oddball composites, like PLA + crushed walnut shells, or PLA + coffee grinds, but these novelty items have had their day and people are more interested in part strength and unusual colors. You can get “glow in the dark” PLA filaments, as well as color-changing PLA filaments, which can be interesting.

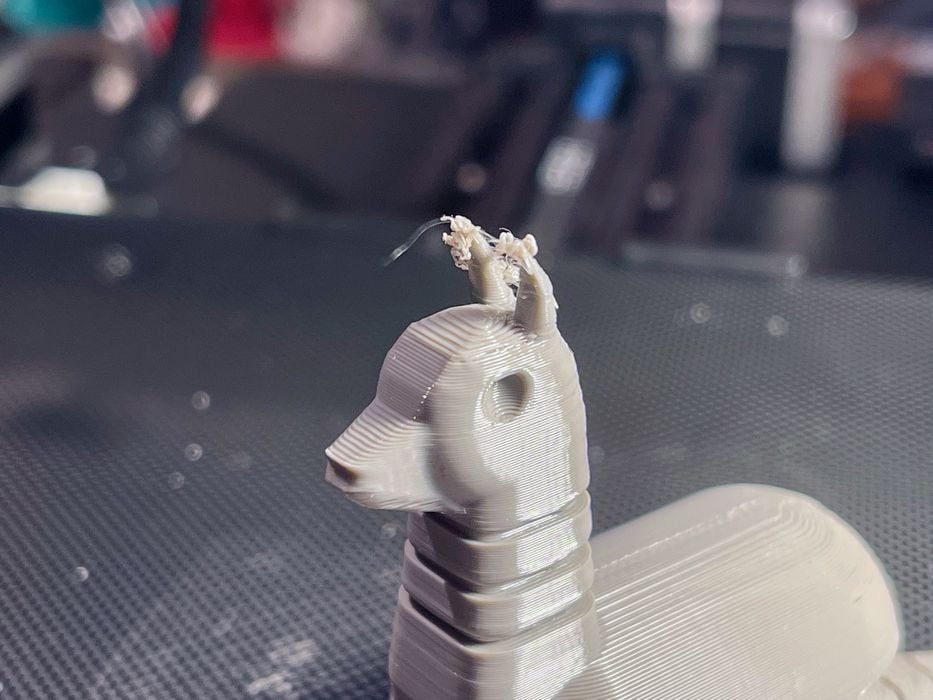

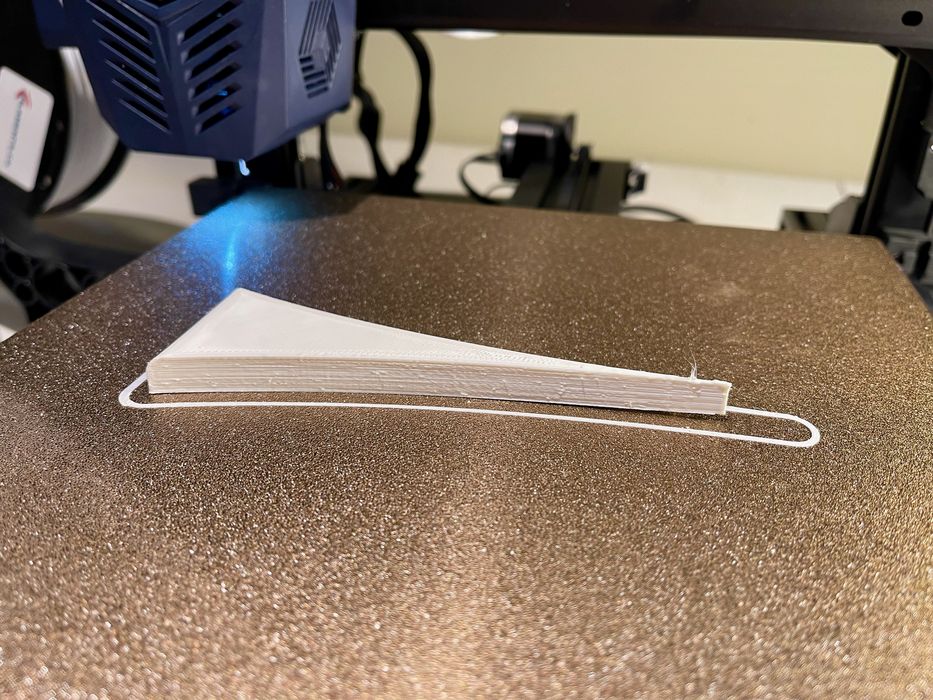

If you do have some PLA filament spools, the best practice is to store them in sealed bags with some desiccant. This keeps the humidity from being absorbed by the filament, and should prevent print failures. If you don’t store PLA properly, it will eventually shatter, as you can see above.

PLA has been around for years, and it isn’t going away anytime soon. However, it will be joined by some up and coming alternate materials, such as PETG.