MatterHackers announced a highly unusual arrangement with the US Navy.

MatterHackers is a California-based 3D print reseller, one of the largest and most well-known in the US. Currently they carry two dozen different brands of equipment, with around 200 unique 3D printer models available. In addition, they offer over 1600 different varieties of 3D printer filament and resins. Yes, they are pretty big.

The news is that MatterHackers has entered a “CRADA” (Cooperative Research and Development Agreement) with the US Naval Information Warfare Center to “identify, test, and collect data on effective, low-cost, expeditionary 3D printing.” I take “expeditionary” to mean “in the field”.

We’ve seen several military experiments with 3D printing in recent years, including a notable metal 3D printing milestone set this week by SPEE3D. All of these projects seek the same thing: simplified logistics.

The military, naval or otherwise, runs on machines of all types and they must be serviced. This means spare parts, and certainly there are vast warehouses of parts for all kinds of mechanisms by all militaries.

The problem is that these parts must be sent to where they’re needed, and that usually isn’t somewhere near a FEDEX drop off center. In fact, often parts will be needed literally in the middle of nowhere — or the middle of the ocean.

In such locations it’s difficult and expensive to move spare parts. As a result, some spare parts are brought along, which generates more expense and trouble.

If only the parts could be produced on site when needed.

Thus there is extreme interest in 3D printing technology to build parts on demand in remote locations. It saves time, shipping, and much more. But the devil is in the details, as we saw with prior experiments with LBPF metal 3D printing at sea: it doesn’t work because the printing process depends on a stable surface, which ships are definitely not.

The MatterHackers project seems quite different from other cooperative research ventures in the past, where specialized equipment was used. Here the goal seems to be to determine the value of off-the-shelf inexpensive 3D printing gear. MatterHackers explains:

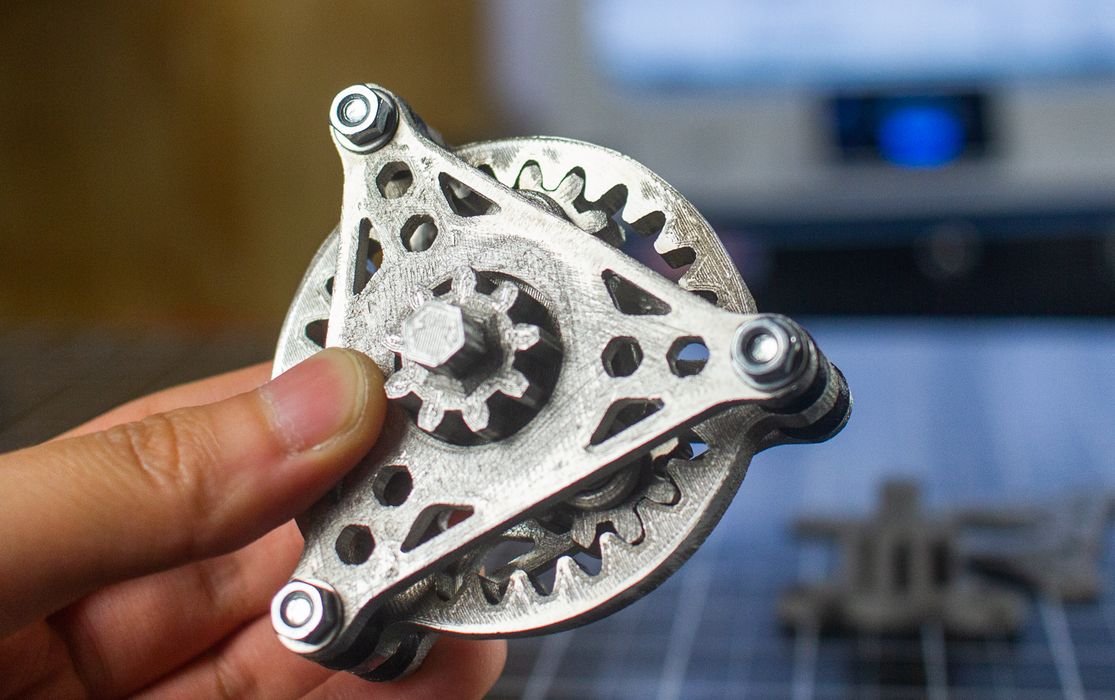

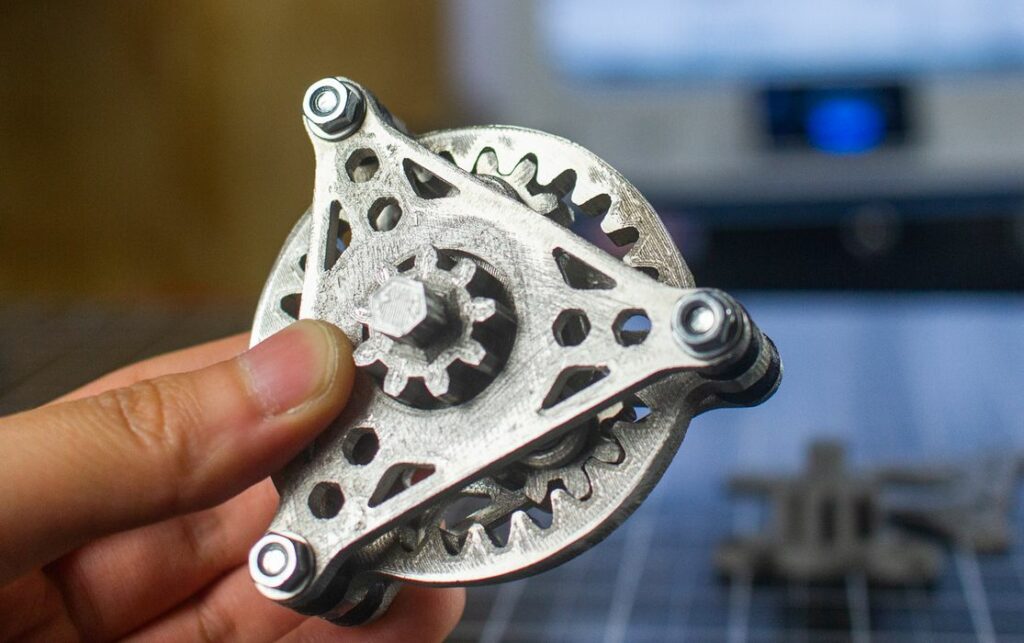

“MatterHackers, in conjunction with NIWC Pacific, will work with the Marine Corps to test 3D printed parts in numerous use-case situations, with successful prototypes being delivered to respective Program Offices for further reliability and durability testing. MatterHackers will collaborate with the aforementioned groups on the design and prototyping of novel additive manufacturing equipment to meet the Marine Corps needs, including the ability to widely ingest available materials of interest, such as stainless steel 3D printer filament that can be debinded and sintered off-site.”

This is a very interesting move by the US Navy, as the use of inexpensive 3D printing equipment hasn’t been done in such an extensive experiment. Previously we’d see the much higher priced commercial 3D printers being tested.

However, in recent years the competency and power of inexpensive 3D printers has dramatically increased, and many devices are now able to produce end-use parts. This capability has apparently been noticed by the US Navy.

MatterHackers is a good choice for this project, as they have access to a multitude of equipment & materials, in addition to their in-house expertise. MatterHackers VP of Strategic Partnerships Mara Hitner explained:

“MatterHackers has been working closely with our neighbors at Camp Pendleton in Southern California for years, and we are so excited to be able to dig deeper into their 3D printing needs with this CRADA. We want to help push those capabilities further with the right machines, materials, and training.”

This looks to be an exciting project, and also demonstrates the significant power of today’s inexpensive 3D printers.

Via MatterHackers