There’s often said to be a “race to the bottom” with desktop 3D printers. What happens when we get there?

When I first obtained a desktop 3D printer more than ten years ago, it wasn’t cheap. In fact, it cost me a couple thousand dollars, and that was a typical price point for the machines of the day.

The worst part was that the machines of that era were actually terrible. They had basically no automation, configuration, consistency and almost always required assembly, sometimes to a considerable degree. The print results were awful, and general knowledge of the topic was rare.

But time heals everything.

In the intervening years we’ve seen significant shifts, some of which are still ongoing.

The eager entrepreneurs that launched the desktop 3D printing revolution 13-14 years ago with a series of open source projects quickly found their designs were — legally — replicated by inexpensive Asian manufacturers and startups.

This choked the revenue growth for many companies, causing them to perish or shift into other markets, such as was the case with MakerBot, Ultimaker and others.

Meanwhile, an avalanche of Asian companies swept through, each releasing new and even more inexpensive equipment. Waves of nameless machines would appear and disappear, sometimes along with the companies that made them.

The price of the equipment started to fall, and this in turn attracted more buyers. Once it was notable if a machine cost less than US$1,000.

A few machines neared the fabled US$100 level, but these were not terribly useful devices. Stripped of features and using the cheapest parts possible, they were not really “at the bottom”.

Lately, however, I sense that things are changing.

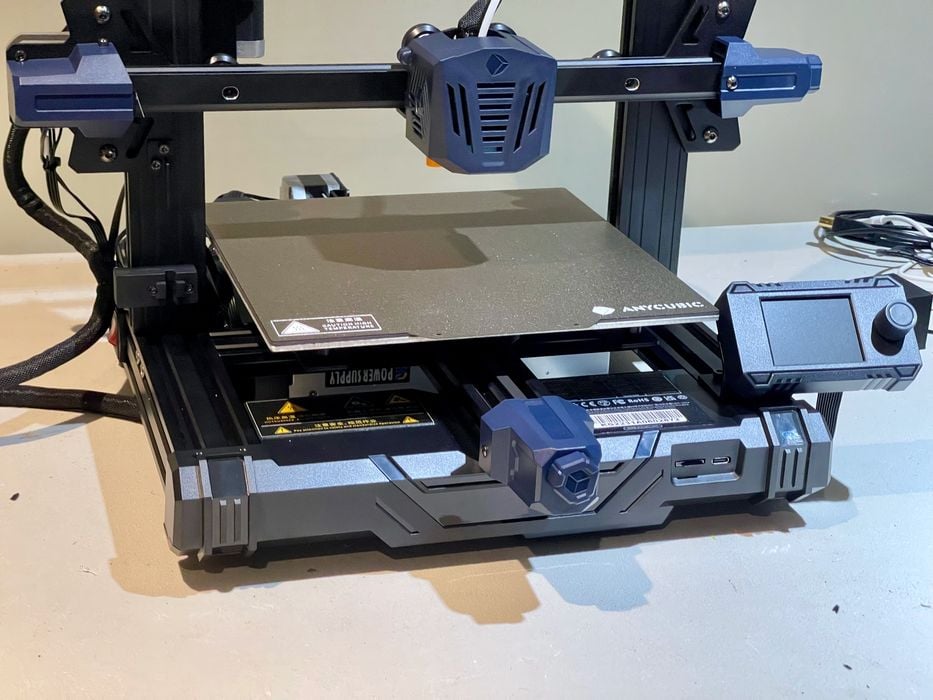

Sure, the price continues to drop, but my suspicion is that they are starting to converge. The current lowest price for a reasonable desktop FFF 3D printer with practical features and quality is now around US$150. I think this is probably where the price will stablize in the long term.

When this occurs — and be certain that this will be a rather fuzzy “when” — the question becomes, “how will these manufacturers compete?”

My suspicion is that they will compete on features, and this is already beginning to occur.

Consider the very useful automated leveling & calibration feature. Originally found only on expensive equipment, it now is available on basically every FFF 3D printer no matter what the price. If the machine doesn’t have automated leveling, I would be very suspicious of the machine, and so should you.

Some of the features likely to become objects of competition could include:

- Easier / fully automated filament load / unload

- Bigger and easier to use control panels

- Automatic cloud-based network control

- Enclosures

- Safety systems, like smoke alarms, etc.

- Default ability to print some engineering materials

- Automated flow control calibration

- Print Wizards

- Automated failure detection

- Continuous 3D printing options

But to be clear, the biggest competitive factor is likely to be print speed. To date most desktop 3D printers are able to manage something between 40-60mm/s of extrusion. That’s ok, but it’s now shown that it is possible to print at higher speeds.

Several projects have emerged that can be the jigsaw pieces for increased speed, like Klipper, which Creality is already experimenting with. There are other projects, like Voron, that provide a way to build a high speed 3D printer on your own. My suspicion is that some of this technology will make its way down towards the bottom.

The result should be incredibly powerful, fast, reliable and safe desktop 3D printers available for US$150-200 in a couple of years.

Either that, or you get the machine for free in exchange for a non-cancelable monthly filament subscription.