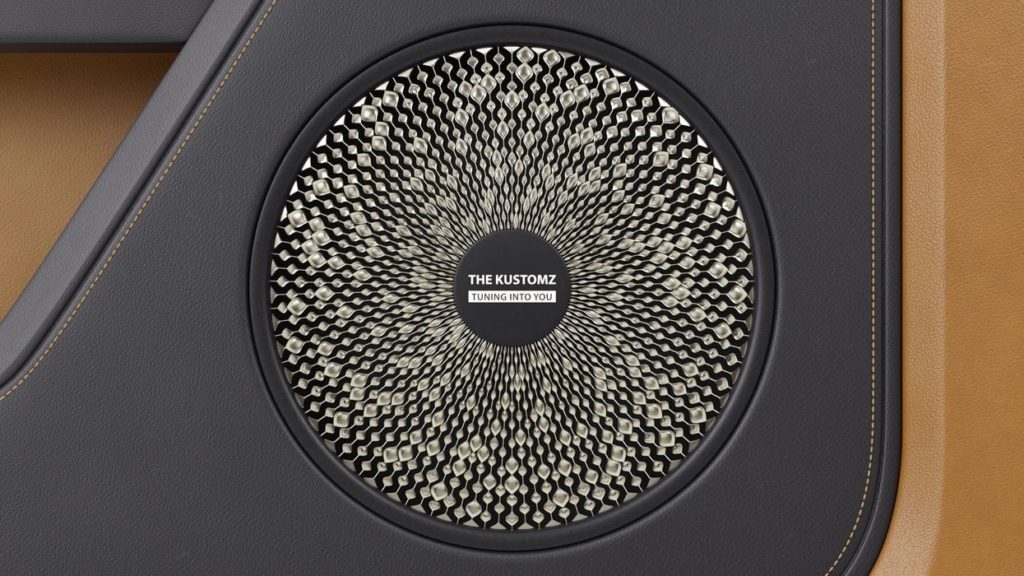

Materialise develops an algorithm to 3D print custom speaker grills that visually represent any song.

Additive manufacturing (AM) makes it easier for luxury brands to customize their products to meet their customers’ every desire. Over the past few years, the 3D-printed luxury goods market has exploded, and many companies are looking for ways to integrate more custom items into their products. Founded in 1990, Belgium-based Materialise develops software solutions and 3D printing services for industries as diverse as fashion and health care. Recently, the company’s engineering design team turned a customization concept into a prototype for 3D-printed speaker grills that visualize any song.

Creating Custom Speaker Grills with 3D Printing

The engineers at Materialise wanted to help automotive companies deliver truly personalized products to their customers. So beyond simply picking the interior fabrics of a car, the engineering team at Materialise thought that their expertise in AM could allow a customer to not only incorporate their favorite song into their vehicle but also see the song in the form of a speaker grill.

The engineering team evaluated multiple 3D printing materials and processes to meet the aesthetic and quality of luxury products, ultimately landing on titanium and stainless steel as the two best materials for custom grills.

Using Rhino with the Grasshopper plug-in and custom APIs developed by Materialise, the company created an algorithm that utilizes frequency and amplitude information from an audio file and turns it into a unique design representation optimized for 3D printing. Currently, the software can only integrate these parameters, but the design team is already looking to broaden the input parameters and expand the types of audio files that can be visualized. For example, the company hopes to be able to turn an audio file of a voice into a visual representation suitable for 3D printing. In this way, customers could choose any audio file to generate their custom grills, whether it be their favorite song or a loved one saying their name.

During the design process, the engineering team conceptualized what they thought different musical elements might look like, such as bass and other beats. With these artistic interpretations, the team then developed an algorithm to take an audio input and create a visual representation ready for 3D printing. Using procedural modeling, the engineers could visualize the tone, frequency and beat of a given song. The final product is a custom speaker grill composed of unique shapes representing each of the different elements of a piece of music.

Read more at ENGINEERING.com