CASTOR has released a report on 3D printed part sustainability, and it has some interesting reveals.

If you’re not familiar with CASTOR, they have developed a unique system for evaluating the printability of part designs. Basically, they scan through CAD files and perform multiple analyses to advise the part owner.

The problem they are solving is the dilemma of a manufacturer with hundreds of part designs that wishes to start using additive manufacturing. They don’t know which parts would be feasible to print, or whether it would be worthwhile financially to do so. CASTOR figures that out automatically.

CASTOR is one of a very few companies that provides this type of analysis, but they offer an additional analysis that I don’t believe exists elsewhere: sustainability.

Just as they are able to compare the cost of manufacturing a design using, say, CNC milling vs. additive manufacturing, they are also able to estimate the energy required to create the part, and the consequent CO2 emissions.

Note that their analysis considers the entire part lifecycle, including material production, product manufacturing, product use, transportation and end of life disposal.

In other words, they can tell you if a given part can be made and used more sustainably just from looking at the CAD file.

While that’s a fascinating feature, CASTOR has recently published a report based on their analysis of some 50,000 part designs. The report focuses on their findings of sustainability for these parts, which are very likely representative of the entire industry.

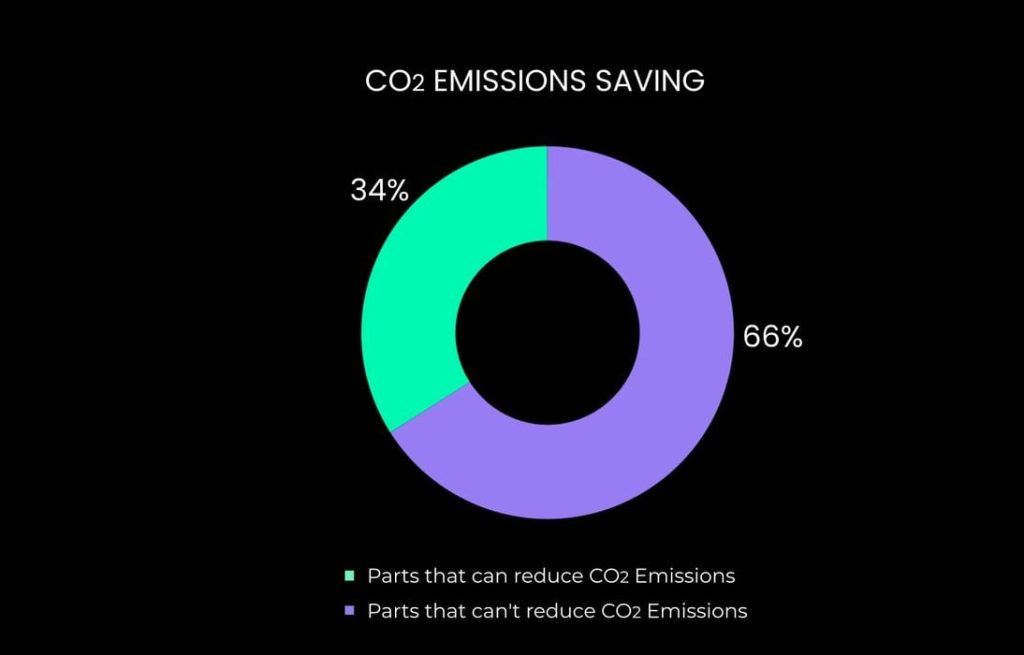

The findings are quite interesting. One is that only 34% of parts can reduce CO2 emissions. They explain:

“While 3D printing isn’t necessarily always the most suitable option for production, there are numerous aspects throughout the product lifecycle where it can have sustainable advantages. The analysis of both metal and plastic parts, encompassing all aspects of Additive 6 Manufacturing f rom the consumption of raw materials to waste management reveals that, out of thousands of parts, 34% of all the suitable parts for 3D printing were identified as having the potential to reduce CO2 emissions.”

However, this changes significantly when complex parts are considered. Apparently only seven percent of “simple” parts could lead to CO2 savings, while 25% of complex parts could. In other words, it’s generally more sustainable to 3D print parts with complex geometries.

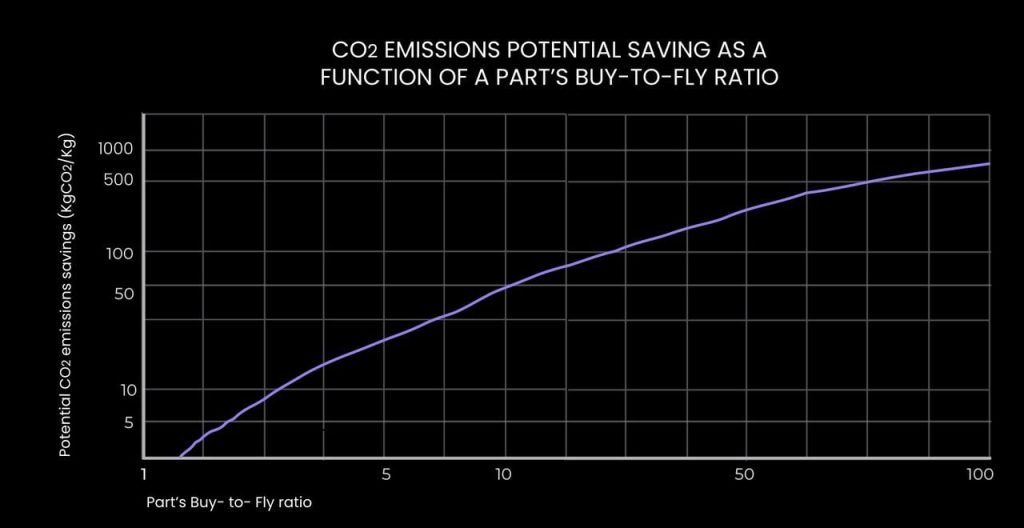

They also found that there his notably higher CO2 savings when the “buy to fly ratio” (amount of material lost during manufacturing) is high, as per this chart:

This suggests that if a manufacturer is seeing a lot of scrap materials from their CNC milling process, then they should consider additive approaches to be more sustainable.

Additive manufacturing often is used to reduce the weight of parts, and CASTOR found that parts with a weight reduction of 40% (typical) will improve CO2 emissions by around 10%.

Finally, they discovered that on-demand printing is more sustainable than the traditional warehoused inventory parts approach. They found a typical injection molding operation would save over three tons of CO2 over a ten-year period.

The report is available to the public at no charge, and I encourage you to take a read. I also encourage you to consider sustainability aspects when designing and printing parts.

Via CASTOR