One of the most frequently asked questions by 3D print newbies is “What Can I Make With A 3D Printer?”

The reason for the ask is that generally people still don’t understand what 3D printers are, and what they can be used to make. There is a suspicion by many that 3D printers can “make anything”, but that is very far from the truth.

3D printers vary considerably in capability. An analogy I like to use to help people understand the difference is this: you might be thinking “3D printers” are a class of related objects, like “automobiles”. But in fact, the variances between 3D printers is more like “vehicles” than automobiles.

You have to decide whether you’re driving, flying, tunneling, or on a journey to the Moon. That’s how different 3D printers really are.

The reason for this variance is that the several 3D printing processes — yes, there are many different processes — make objects in different ways, sizes and in different materials. Very often 3D printing processes and equipment are limited to specific materials, making the choice of machine straightforward. Or there’s no choice at all because the material isn’t usable in 3D printers.

There’s different ways to answer this question. One way might be to focus on the materials and processes, so let’s start there.

Plastic 3D Prints

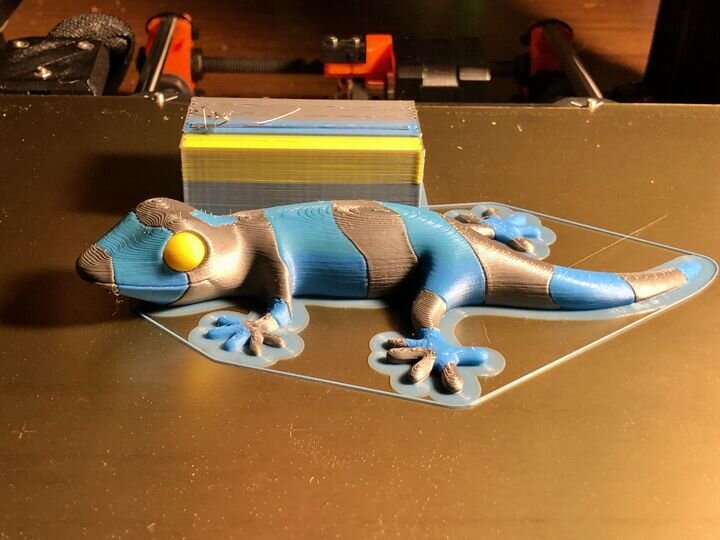

Many inexpensive desktop 3D printers can produce objects in thermoplastic materials. These are plastics that soften when heated, and solidify when cooled. Typically these are used in filament (or “FFF”) 3D printers.

There are also 3D printers that use fine thermoplastic powder and lasers to produce high resolution objects.

Resin 3D printers also produce plastic objects, but most often they are “thermoset” materials, that can’t be reshaped through heating as thermoplastic materials can be.

Sometimes “composite” materials are 3D printed, which are a mix of a plastic and some other substance that offers interesting properties. For example, some materials include glass fibers, carbon fibers, wood fibers, ceramics, etc.

Metal 3D Prints

There are several processes that can produce metal 3D prints, but most of them are quite expensive.

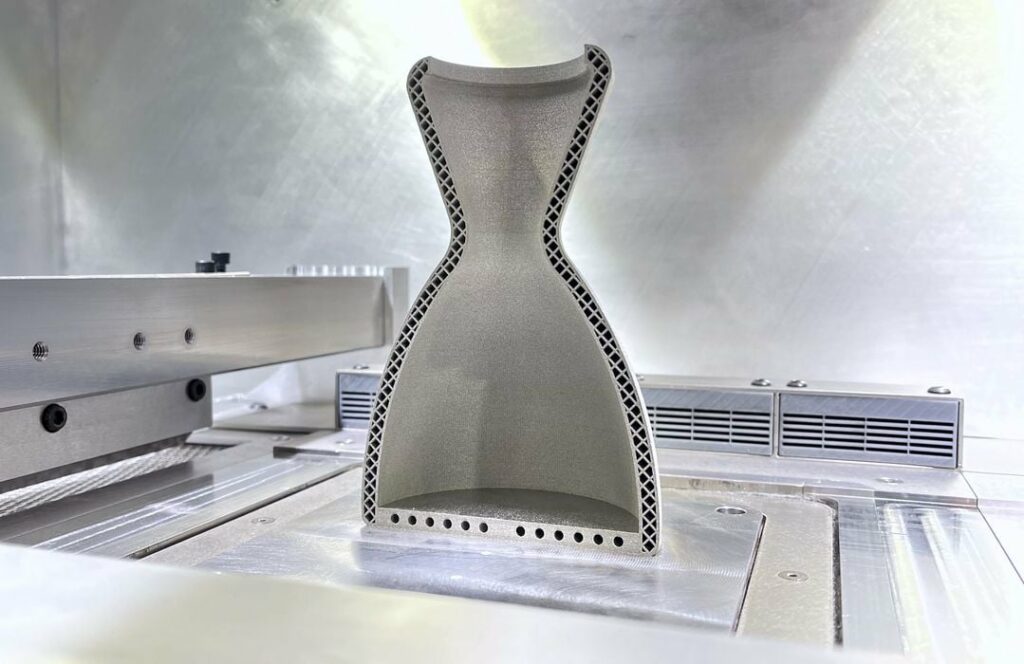

PBF 3D printing involves use of a flat bed of powder and lasers to form objects layer by layer. These days this approach is mostly used to produce parts for the aerospace, automotive and healthcare industries.

It’s also possible to 3D print metal parts by using a mix of thermoplastic and metal powder: the prints are sintered in a furnace after printing to remove the plastic and fuse the metal particles together.

Multi Material 3D Prints

One thing to remember is that almost all 3D printers today produce objects in only a single type of material. That material might have different colors, but it’s all one metal or one plastic.

There are a few sophisticated devices that can 3D print in multiple colors, but even fewer that can do multiple materials.

This means that complex objects — objects with more than one material in them like every device you own — are impossible to 3D print. You can’t 3D print a smartphone because it includes plastic, glass, metal, electronics, batteries and other stuff that isn’t printable.

This means that 3D printer operators are normally restricted to producing single-material parts or simple mechanical mechanisms. It is possible to print several parts and then assemble them manually together to make simple machines.

How Big Can I 3D Print?

This is a frequently asked question, but the answer is not obvious. At first, you might think the answer is “anything that fits inside the 3D printer”, and you’d be partially correct.

But the dimensions of the 3D printer lie. If a printer has a build volume of, say, 200 x 200 x 200 mm, then you’d think the maximum object might be 200mm in length. However, it’s possible to 3D print objects at an angle and they can be a bit longer.

It’s also possible to use a CAD system to chop up a larger design into several parts. These can be 3D printed separately, and then assembled together into the larger object. In that case the 3D printer is really unlimited in the size of part they can produce.

On the other hand, the longer the 3D print, the more likely it is that you’ll encounter a failure of some kind. For this reason larger prints are not the first choice for 3D printer operators. Many more smaller objects are produced than larger pieces.

What Objects Can Be 3D Printed

Another way to answer this question is to see what kind of objects can be 3D printed.

Generally, 3D printers have few geometric restrictions: you don’t have to, for example, take into account removing the part from a mold, as you do in casting or injection molding. This allows 3D printers to create enormously complex objects with ease, items that would be impossible to build in any other way. This is why you sometimes see 3D printed objects with a kind of skeletal form: this is the minimum amount of material to meet the physical requirements for the part, and makes the part lightweight.

Because of this ability, 3D printers have been used to produce all kinds of objects, limited only by the designer’s imagination.

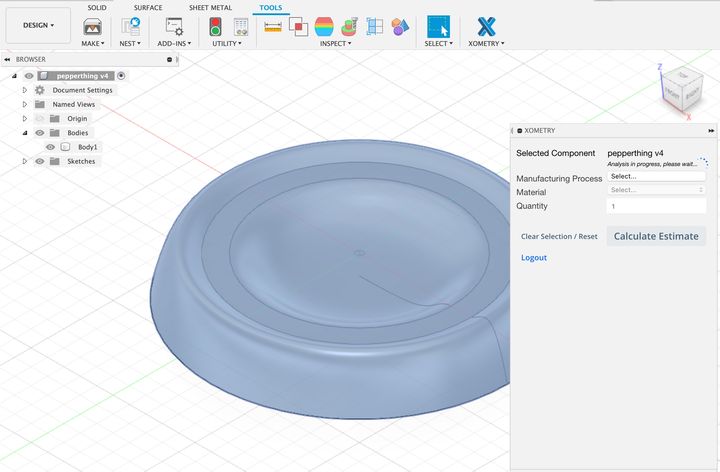

But that’s the catch: any object to be 3D printed MUST be formally designed in a software CAD tool first. It’s analogous to paper printing: you can’t print “a letter to someone” unless you’ve typed it into an editor and formatted the paragraphs. Here instead someone has to create the 3D model of the part first, and that can be challenging.

While everyone can type a letter, very few people are skilled in using CAD software, which can be quite complex, expensive and require months of experience. For this reason many 3D printer operators are restricted to using other people’s 3D models that are provided online.

So in one sense, the answer to “what you can 3D print” might be “what you can find online”. This is why many 3D printer operators eventually learn how to design their own parts.

Making Your Own 3D Printed Parts

A common belief is that one can use a 3D printer to make replacement parts for household items, thus saving time and expense of buying spare parts.

This is both true and false.

It’s true if — and only if — you are sufficiently skilled in 3D CAD design to somehow design the required part yourself for 3D printing.

Sometimes this is easy: a hose connection might simply be a cylindrical shape of a certain diameter. On the other hand, the part might be extraordinarily complex and require tricky dimensional tolerances, like a pivoting mount for a unique mobile camera. Some things are easy to design, others are very hard or nearly impossible. The decision is really how much time you want to spend making the design, because the printing takes only a few hours.

If the desired part is too complex, then it’s not worth designing and 3D printing, so in that case you can’t 3D print your own spare parts.

One might ask why the designs aren’t provided by the product manufacturers, since they obviously made the design to create the part for their product? The answer is that this basically never happens.

The reason for this is that they’d rather sell you that replacement dishwasher knob for US$39 instead of giving you the 3D model to print it yourself. Maybe they could sell you the 3D model for US$30 and save themselves the trouble of stocking parts, but few people would pay that much for a 3D model, and if it’s too expensive, then the 3D model will be pirated.

The end result is, once again, you’re designing your own parts for 3D printing.

The Answer

After all this, the answer to “what can I make” might be a bit clearer. It depends on equipment, skills, materials, software capabilities and desire.

But yeah, you can 3D print a lot of different things.