Vlare is shaking up the world of resin 3D printing.

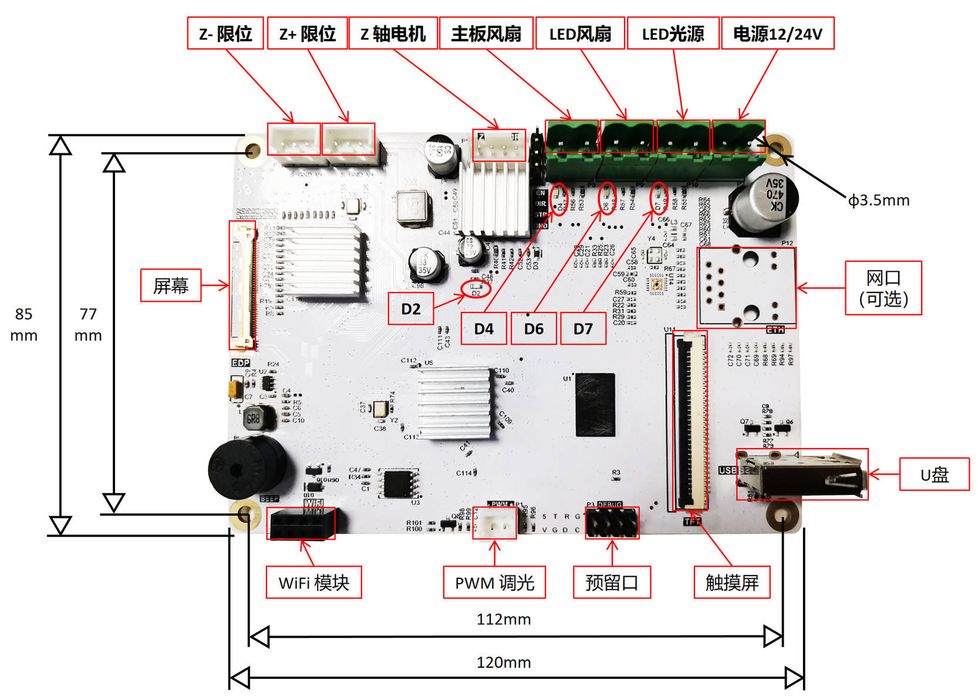

Shenzhen-based Vlare is a startup focusing on the electronics and software behind desktop resin 3D printers. Late last year they announced their intent to develop a new controller board, specifically designed for use in resin 3D printers.

Why is this a big deal? It’s because the current state of controller boards and associated software is a bit messed up.

Most inexpensive desktop resin 3D printers use boards from Chitubox, and this is why many machines are accompanied with Chitubox slicing software. In fact, many users are more familiar with “Chitubox the slicer” than they are with “Chitubox the controller”, which is inside the machine they’re using.

However, Chitubox isn’t the greatest slicing tool, and some seek alternatives. One I’ve used is the Lychee Slicer, which provides much better support structure options. However, it sometimes doesn’t work with new resin 3D printers, and this is because of the complex nature of the Chitubox controller and its licensing.

Vlare is trying to change all this, and make the whole environment a lot more seamless. The company, which has been making OEM LCD panels, noted the issues in the current environment. Vlare’s Daniel Lee explains:

“The lack of controller options and functions has placed limitations on software choice, which has been a chokehold for new ideas and applications. This leads to many similar-looking printers from OEMs, and over-competition leads to vanishing margin and even less willingness to innovate. The low price is undoubtedly great for users in the short run, but it means less innovation and everyone gets less in the long run.”

This is very true. There is actually very little difference between many inexpensive resin machines these days, and that’s because they are all constrained by the controller boards they’re using.

Vlare’s controller board, “Core”, has these key goals:

- A robust controller board that supports an open file format with no encryption so 3rd party software can work without complex SDK terms or wasting CPU cycles to decrypt.

- A Future-looking Data Structure to support features such as multiple-exposures per layer, variable heights, advanced layer change movements, etc.

- A full range of connectivity so OEMs can customize and innovate to differentiate their products. This includes serial, SPI, and network.

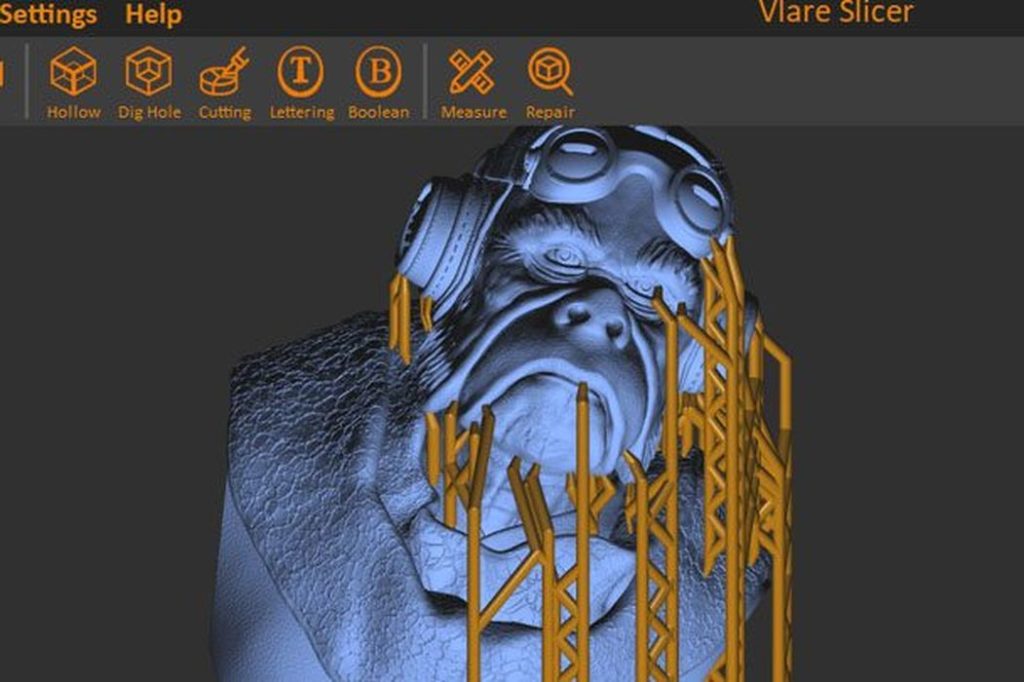

- A FREE, full feature slicer that is quick to learn, makes it easy to print well and includes advanced functions for professionals.

These are noble goals that I expect everyone to welcome. The science of resin 3D printing definitely needs more flexibility in job setup to ensure quality and reliability, and this is certainly one way to achieve that.

The Vlare Core can handle a wide variety of LCD panels on the market, ranging from 2K to 8K models, as well as different styles of control panel displays. It can also handle a range of networking connections, including WiFi, Ethernet, SD cards, etc.

So far few 3D printer manufacturers have adopted the Vlare Core as a controller board, likely because it has only been available for a few months. One machine we recently saw that uses the Core board is the new Peopoly Phenom Forge 3D printer.

However, as time passes it’s likely more resin 3D printer manufacturers could adopt the Vlare Core board due to its more advanced functions. In fact, the mere presence of the board may itself be a marketing feature. Peopoly certainly made a splash in their announcement material about the inclusion of the Core board, so it’s highly likely other manufacturers may do the same.

Via Vlare