In Ukraine the Victoria Hand Project employs 3D printing to make prosthetic care accessible to the underserved.

The Victoria Hand Project

Originating as a university research endeavor in 2015, the Victoria Hand Project quickly matured into an impactful humanitarian cause. Addressing challenges from financial limitations to inadequate governmental support, this Canadian charity has, with the aid of UltiMaker 3D printers, delivered cutting-edge prosthetic technology to those who would otherwise lack access. From its inception, Victoria has created collaborations with clinics in 11 nations, with the most recent being Ukraine.

3D Printed Prosthetics

“3D printing offers a solution to traditional prosthetic limitations,” states Nick Dechev, the founder of Victoria Hand Project. Lightweight and customizable, 3D printing shines especially in crafting sockets for upper limbs.

The ‘Hands for Ukraine’ initiative, spearheaded by the organization in the summer of 2022, seeks to provide sustainable prosthetic care to those affected by the ongoing conflict with Russia. But Victoria’s approach isn’t just about supplying devices. They offer various 3D printed prosthetic hands tailored to individual needs.

Crucially, they emphasize the ability to 3D print the prosthetic arm socket directly at the partner clinics. This innovation not only reduces expenditure but also provides local communities with new 3D printing skills and other tech capabilities.

COO Kelly Knights underscores this, explaining:

“We ensure everything is produced in-house, in-country. For Ukraine, this means Ukrainians crafting hands for their fellow citizens, available on demand.”

The Tech Behind the Victoria Hand Project

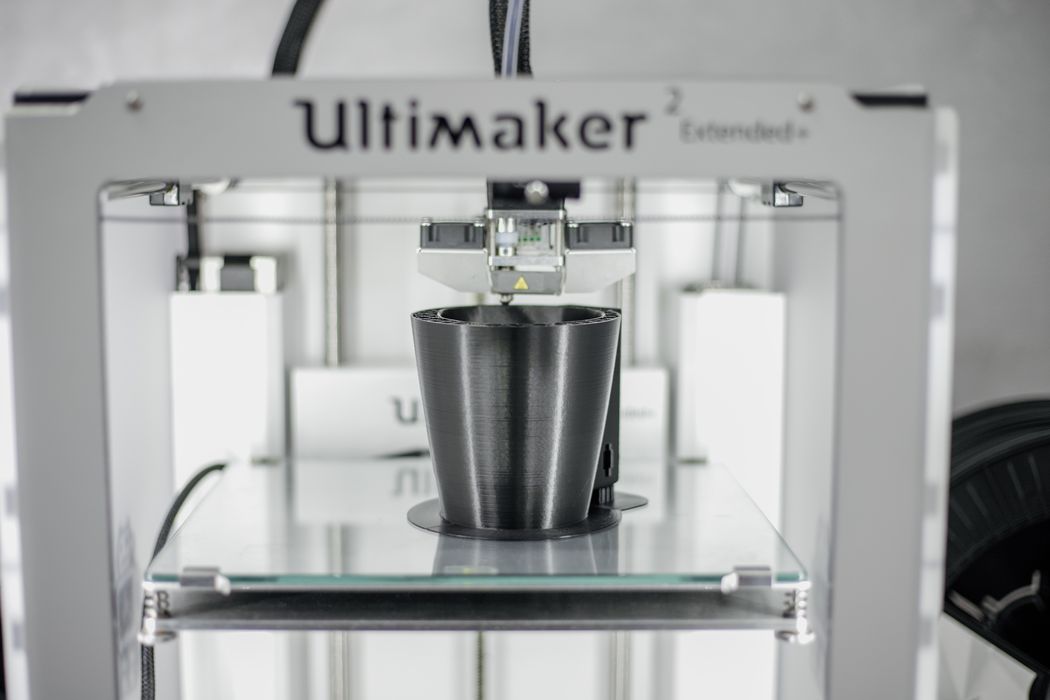

The Victoria Hand Project’s operations are based on UltiMaker 3D printers. The team’s trust in these printers has ensured consistent prosthetic production across global sites. As project CEO Michael Peirone believes, standardizing on UltiMaker printers offers an ease of use and maintenance, crucial for partners unfamiliar with 3D printing.

Material choice is equally crucial. They primarily use PLA, known for its printability and skin-friendliness. Specifically, the UltiMaker printers use Forward-AM’s BASF PRO1 material to produce the prosthetics.

The Victoria Hand: A New Prosthetic

The Victoria Hand, among the first prostheses to be 3D printed, is a unique blend of 3D printed and metallic components. Designed for simplicity, durability, and utility, this prosthetic offers articulated fingers and thumbs. While the palm and fingers are 3D printed using PLA, the fingertips use silicone, cast to precision. The internal components, built from robust materials like stainless steel, ensure longevity.

Envisioning the Future

The Victoria Hand Project sees 3D printing as a game-changer in the prosthetics realm. Custom limb socket fittings, which are intricate and tailored, can be easily achieved with 3D printing, a task challenging — and often expensive — when done with traditional manufacturing.

The organization intends on growing its impact by diversifying its prosthetic and orthotic offerings. They aim to set up community-based print centers to produce an array of healthcare devices, thereby amplifying local healthcare capacities.

The Victoria Hand Project’s global outreach makes prosthetic care both accessible and affordable, something particularly important in regions in crisis. As they transform lives with each 3D printed prosthetic, they also epitomize the potential of technology to unite and empower global communities.