Exaddon produces a unique 3D printer that can produce micro-sized metal objects.

The Swiss company was originally part of Cytosurge, a biotech company working in the fields of CRISPR, mechanobiology, neuroscience, virology and nano printing. Due to significant interest in their unusual metal printing technology, it was spun off as independently-operating Exaddon in 2019.

I’m sure you’re interested in the equipment specifications, but let me give you a warning: the Exaddon CERES 3D printer has to be about the slowest 3D printer I’ve ever encountered. It’s top printing speed is four micrometers per second (that’s 0.004mm/second, about 15,000 times slower than a typical desktop 3D printer.)

That’s ok, because the CERES’ print volume is rather small, at only 15 x 15 mm, and object sizes ranging from 0.001 to 1.000 mm. However, the 3D accuracy of the positioning system is also notable: 250nm (that’s nanometers, not millimeters) in the XY axes, and only 5nm in the Z axis.

How does Exaddon manage to 3D print such tiny objects in such incredible resolution? Their additive micromanufacturing technology (“µAM”) uses an electrochemical process.

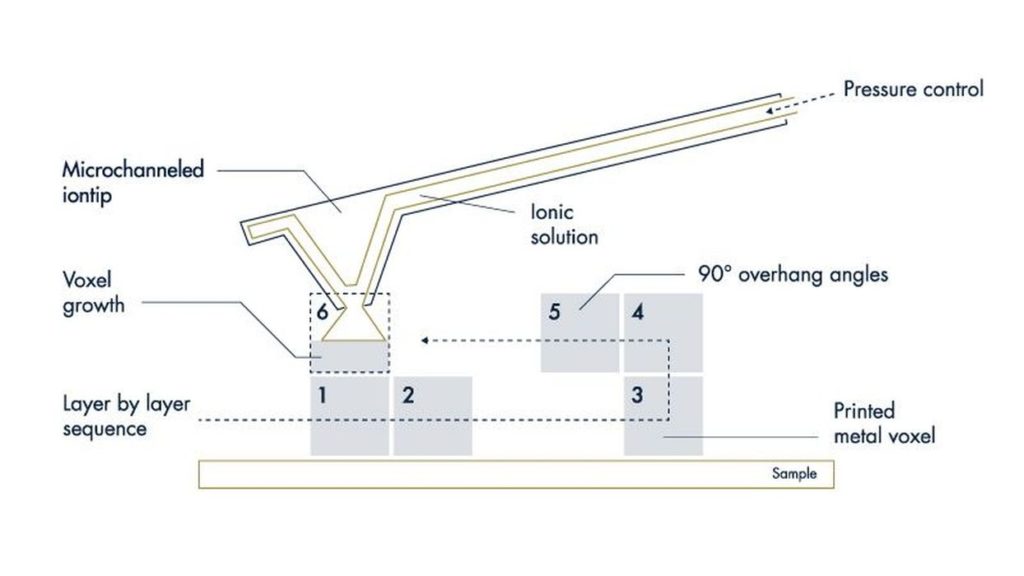

It’s essentially an extremely small pinpoint electroplating system. The CERES includes an “Iontip” print head that channels metal ions toward the print surface, which is surrounded in a bath of electrolyte. Electrochemical action causes the metal ions to bind to the surface. This is repeated as necessary to form voxels that can be gradually built up into the desired object geometry.

The position of the Iontip is controlled by an optical sensor that can determine when the voxel is complete. This seems to be the key to the motion system’s positioning accuracy.

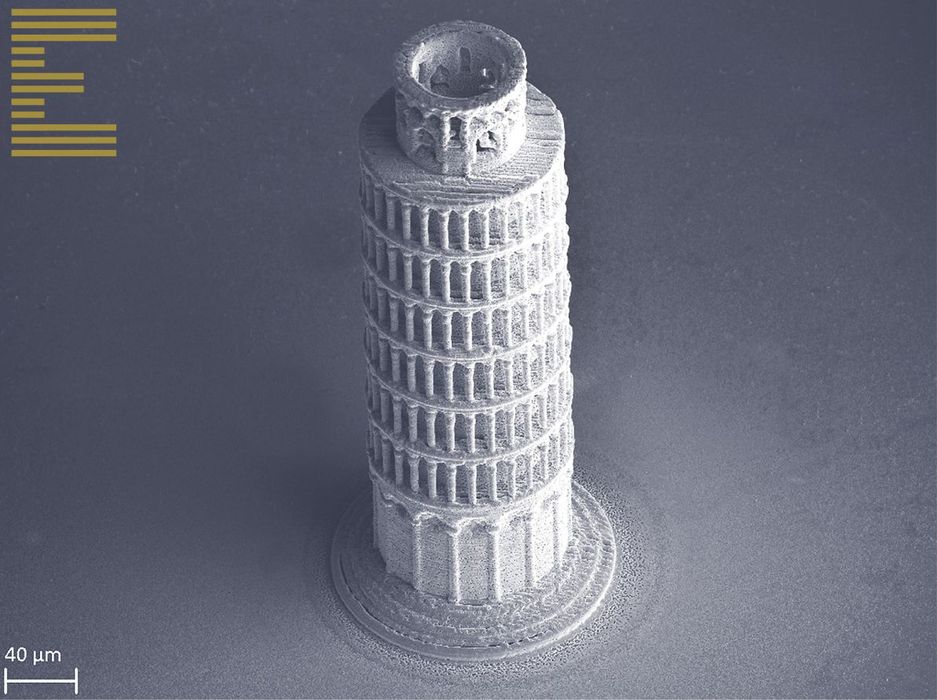

Here’s an example of a test print from Exaddon:

Aside from the extremely small metal objects that can be produced on this device, it also operates at room temperature: electroplating does not require heat, unlike most other metal 3D print processes. There’s also no post-processing required, as is required on virtually all metal 3D printing systems.

One other very interesting property of µAM is its ability to 3D print overhangs. Here you can see a diagram showing a full 90 degree overhang. While this capability likely has something to do with the extremely small sizes involved, it’s still quite impressive and would lead to incredible object print quality and unusual geometries.

What would you make with the CERES? Exaddon suggest applications such as high frequency technologies, neuroprostheics, semiconductors, MEMS, packaging, helix structures, watchmaking, copyrighting and others. Anywhere a small, complex metal object could provide benefit, the Exaddon CERES could fill that need.

To provoke your imagination, take a look at this video showing a microscopic metal spring produced by the CERES being tested. Note the scale involved:

The CERES appears to be a very powerful metal 3D printer for tiny objects. However, it’s so new that it may be the company may be challenged to scale because many companies may not yet realize what they could achieve with this technology.

Via Exaddon