Researchers at the University of Virginia have been experimenting with some highly unusual 3D printing material.

Instead of polymer, ceramic, metal, concrete or even food, they are using living soil as their 3D print material.

While this may sound like pure madness, there is a method here.

Consider that the soil, once deposited into the desired shape, will operate as normal soil does: things grow in it. By preparing an appropriate mix of soil — and seeds — it is possible to print objects that would be the base for predictable plant growth.

Why would you want to do this? I can think of a couple of reasons.

One is to use biology to reinforce the material. Plant growth includes roots that would traverse the structure, much like continuous carbon fiber is used to reinforce mechanical part prints.

Another reason is the incorporation of biology into architectural structures. It’s now known that there are ecological advantages to do so. Consider the use of “natural” roofs where grass is grown instead of using normal roofing materials: the buildings are cooler and the greenery is attractive.

But those implementations are pretty basic: flat roofs.

What if you could do that sort of thing in three dimensions? What if the complex geometries offered by 3D print technology could be used to produce living soil structures?

UVA Assistant Professor Ehsan Baharlou explained:

“We moved to soil-based ‘inks’ to derive additional benefits from circular additive manufacturing. We are working with local soils and plants mixed with water; the only electricity we need is to move the material and run a pump during printing. If we don’t need a printed piece or if it isn’t the right quality, we can recycle and re-use the material in the next batch of inks.”

This could solve the issue of expensive 3D print materials when operating in regions where they are unaffordable. Potentially this development could enable 3D printing of soil-based homes where construction costs are high.

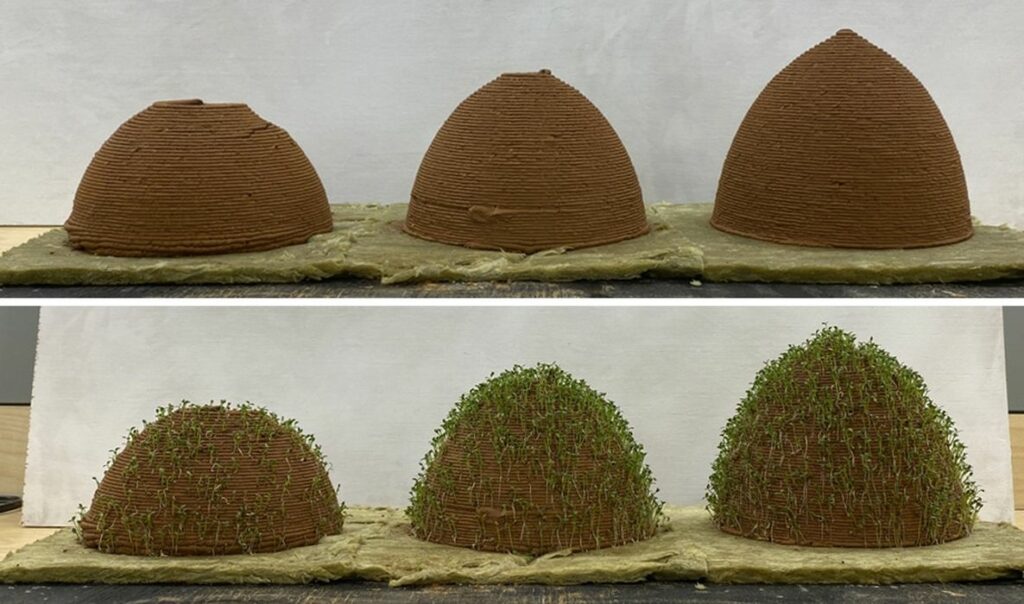

Small-scale prototypes of the concept were developed, and were able to 3D print small structures that did “come alive” when the embedded seeds germinated.

What foliage is being printed here? It turns out the researchers selected genus sedum, or Stonecrop. This species is apparently frequently used for “green roof” projects, and is a type of grass. One of Stonecrop’s properties is that it is somewhat resistant to drought, making it ideal for geometries that present more surface area for drying than flat surfaces.

This is quite a project, because it involves significant work to identify proper materials. While there have been projects to 3D print clay or soil previously, this material must also ensure that embedded seeds can actually survive and thrive.

The concept was scaled up to a 1m+ build volume by means of a robotic arm that held the extrusion mechanism. This should allow building of larger and more complex soil structures.

Where could this technology be used? I suspect one end-goal could be to add it to construction 3D printing projects, where green building elements must be added to a structure. Today’s flat roofs are easy to make: just spread the soil and toss in some seeds. But how do you do that when the building is 3D printed and has a crazy geometry? That’s where you light up the soil printer to match that geometry and apply the living soil.