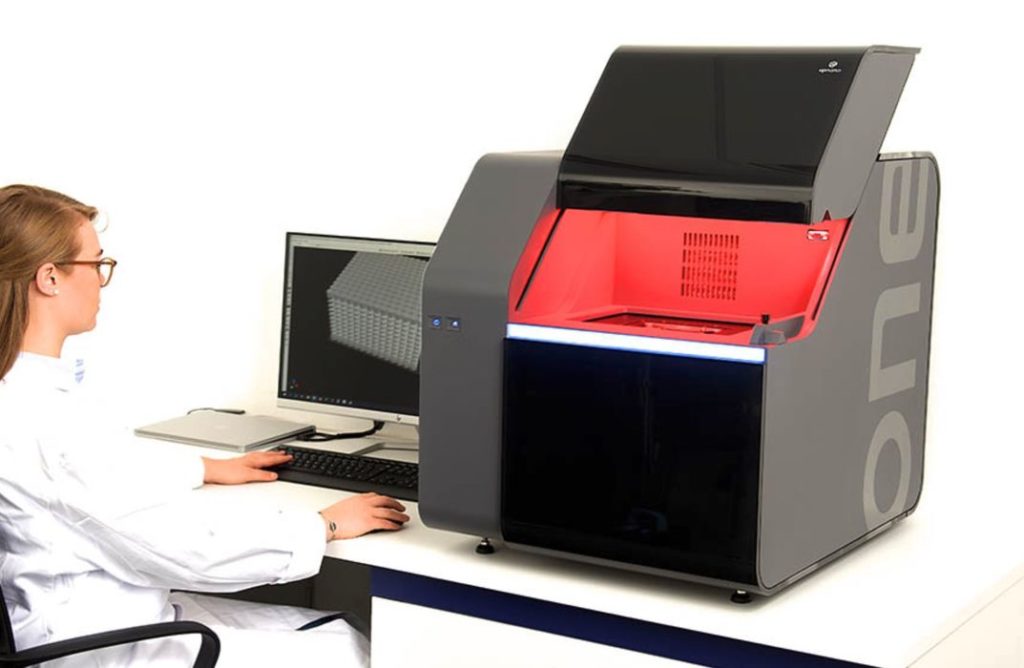

There are few nano-scale 3D printer options, but one comes from UpNano.

UpNano is a 2018 startup based in Vienna, spun off from research that took place at TU Wien. The key technology leaders at UpNano spent years at TU Wien developing “several generations” of multiphoton high-resolution 3D printing systems, and now that tech is being commercialized by UpNano.

Multiphoton 3D printing is a resin process involving laser energy, but is quite different from SLA. SLA involves moving a powerful laser impact dot across a vat of photopolymer resin, causing solidification where the energy lands. The resolution of the SLA prints is proportional to the size of the laser dot.

The difference with multiphoton 3D printing is that the laser energy is tightly focused to an extraordinarily small area. The resin absorbs two photons and begins polyermization in the affected area. This extremely small active area enables equipment to 3D print very small structures measured in nanometers. Sometimes this process is referred to as “2PP”, or two photon printing.

UpNano has built the NanoOne, their flagship 2PP device, which also has a bioprinting variant for printing with living cells.

UpNano’s tech is unique among nanoscale printers in that it can achieve “macro” sized objects if required. The build volume is a rather large (for nanoscale printing) 100 x 120 x 40 mm. This is about the volume of high resolution jewelry SLA-style 3D printers, yet here you can print in very high resolution.

The smallest horizontal feature is 170nm (that’s 0.00017mm, pretty small!) The smallest vertical feature is 550nm (0.00055mm). Obviously, these feature sizes are so small you cannot see them without use of a powerful microscope.

In spite of the high resolution, the NanoOne is able to print 200 cubic mm per hour, which is slow for macro-sized objects, but perfectly acceptable for small items with incredible resolution. UpNano said their system can be “100 times faster” for production throughput as compared to other systems.

What can this incredible system achieve? Let’s look at some example prints.

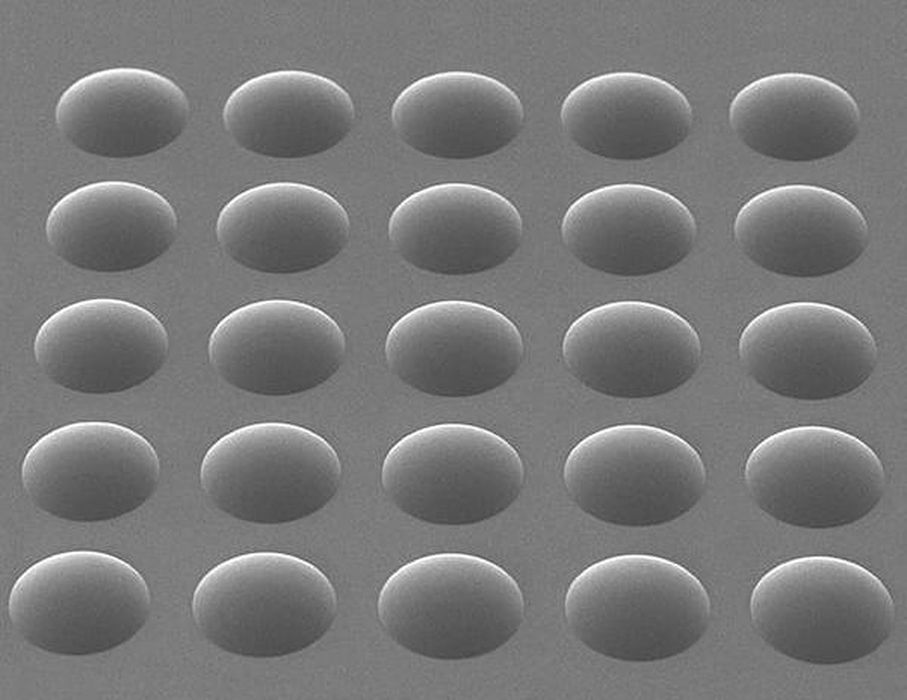

This is an array of micro lenses that could be used for optical applications:

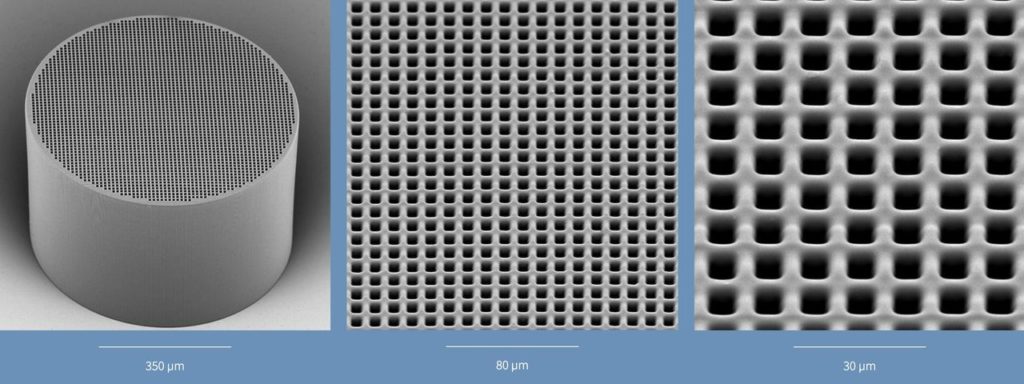

Here is a microporous filter containing an amazing 3,521 channels all within half a millimeter diameter!

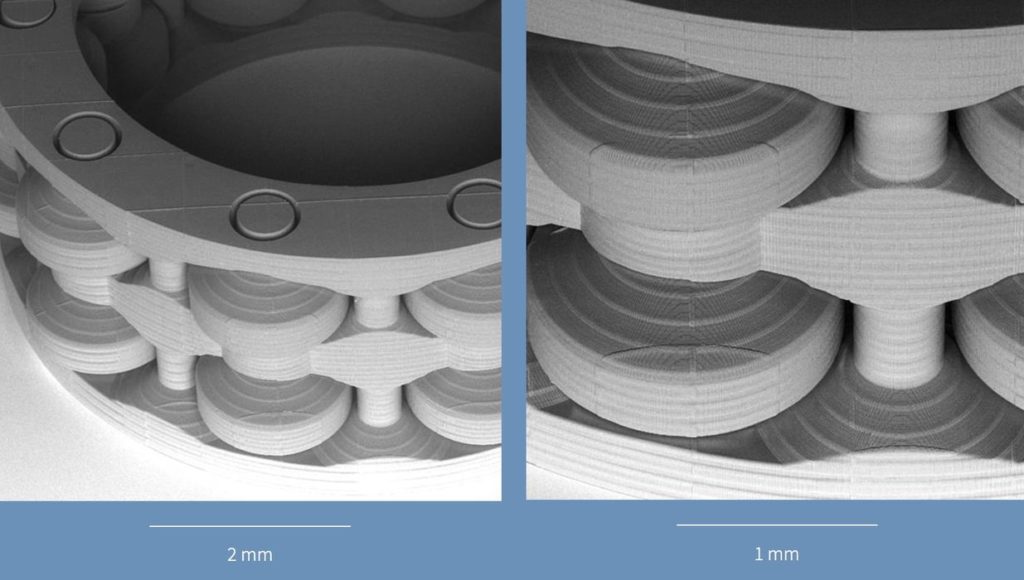

This is a microscopic roller bearing, showing that it is possible to 3D print machinery at this scale:

This is an incredible device that could be used to produce all manner of complex microscopic elements for a wide variety of applications.

Recently the company announced they are opening operations in the US directly to enable more easy access to their technology. In addition, they have also expanded their factory capacity, so they are able to service increased demand from new markets.

Via UpNano