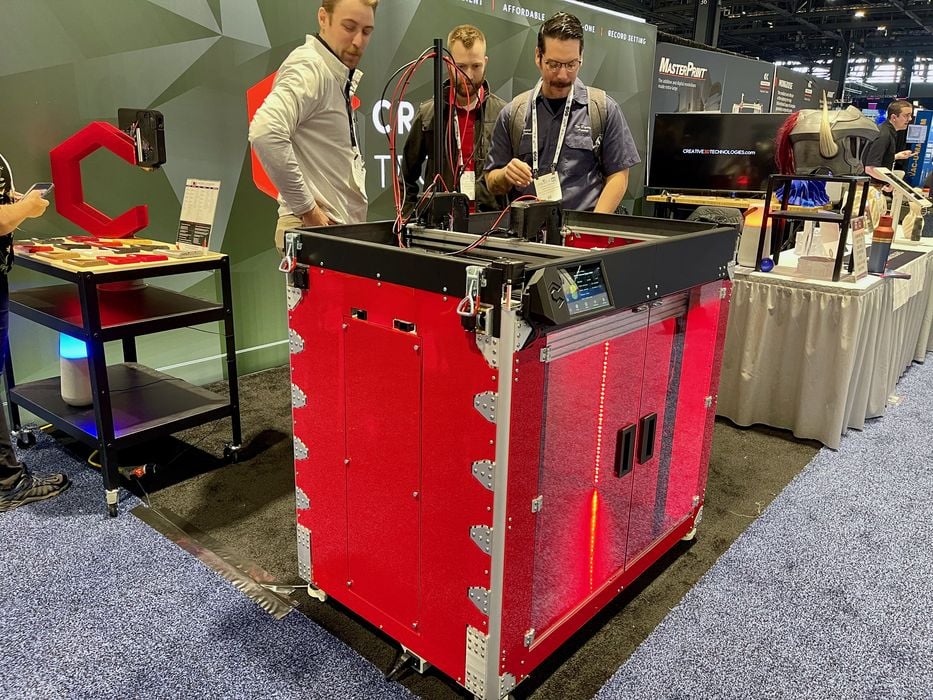

We had a chat with Creative 3D to learn about their latest professional 3D printer, the EVO.

The Austin-based company has been around for 3-4 years now, and their previous device, the Duo, was quite successful. Now they’re moving on to a larger and much more interesting machine, the EVO.

The EVO boasts of high speed, precision printing, reliability and the ability to print in a wide variety of materials, which sounds like an excellent combination for most professional 3D printing operations.

Indeed, the EVO is able to handle both abrasive filaments, such as carbon fiber-infused materials, as well as soft and flexible TPU filaments. The EVO has two print heads, and both are fully capable of printing the entire suite of materials.

One reason for the EVO’s ability to handle a variety of materials is that the build chamber can be heated to 90C, removing most of the thermal gradient that causes warping during printing. The print surface can be heated to a rather high 150C, much higher than most print surfaces that top out at 100 or 110C.

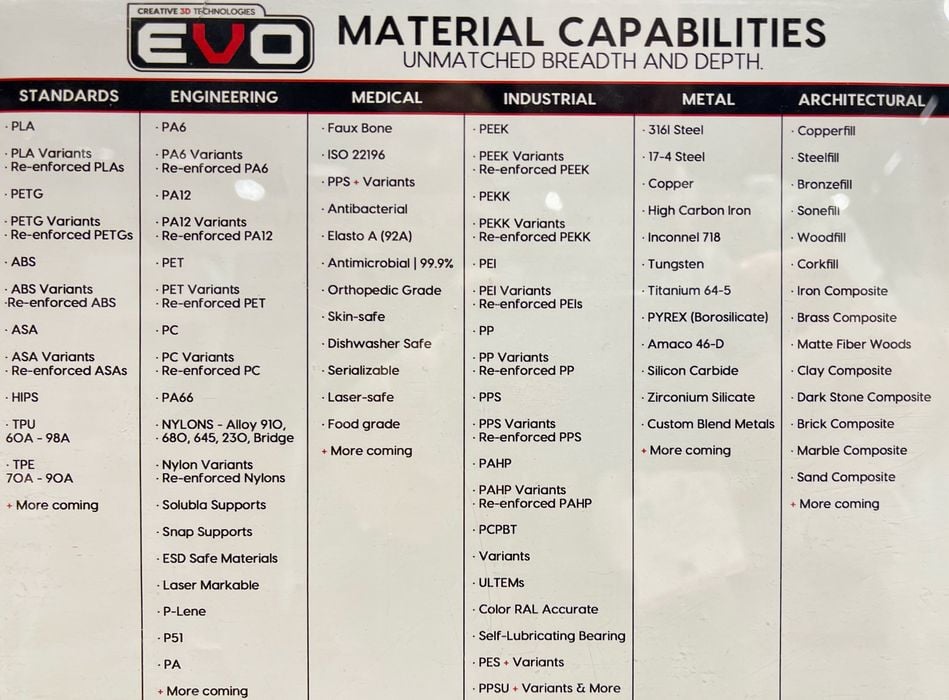

This chart shows the current list of materials available for the EVO. Note that when I say “available”, I mean they have been tested and tuned for the machine. Creative 3D told us they’ve been working with 20 different material brands, and they’re likely to increase that in the future.

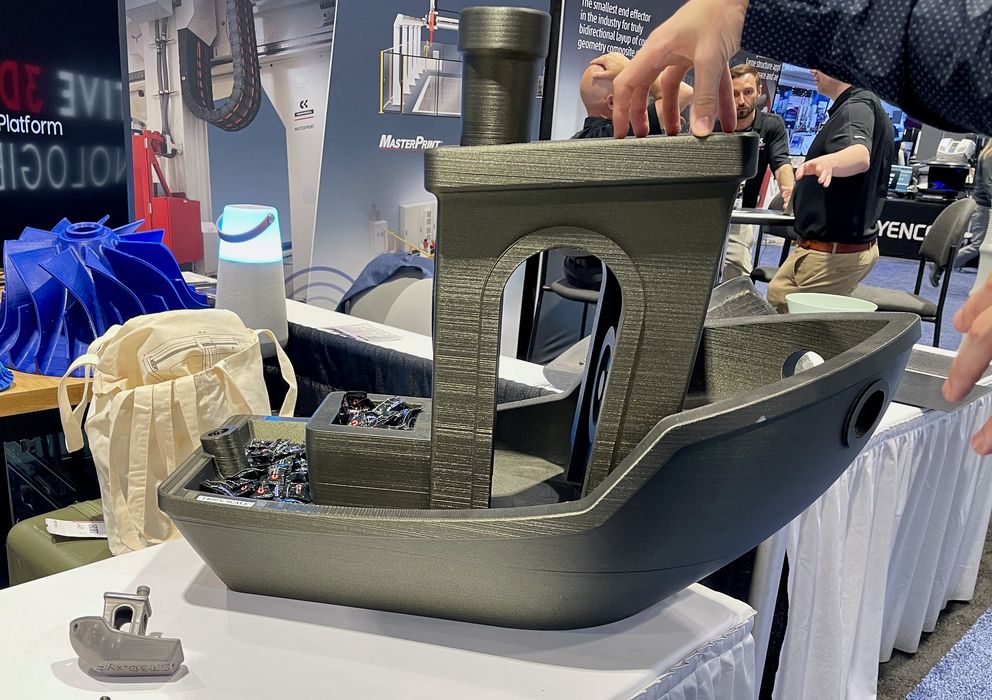

The EVO is a rather large machine, with a build volume of 440 (for dual printheads) x 775 x 780 mm. This enables it to print enormous parts, such as the demonstration #3DBenchy shown above. This print apparently took eight days to complete on the EVO.

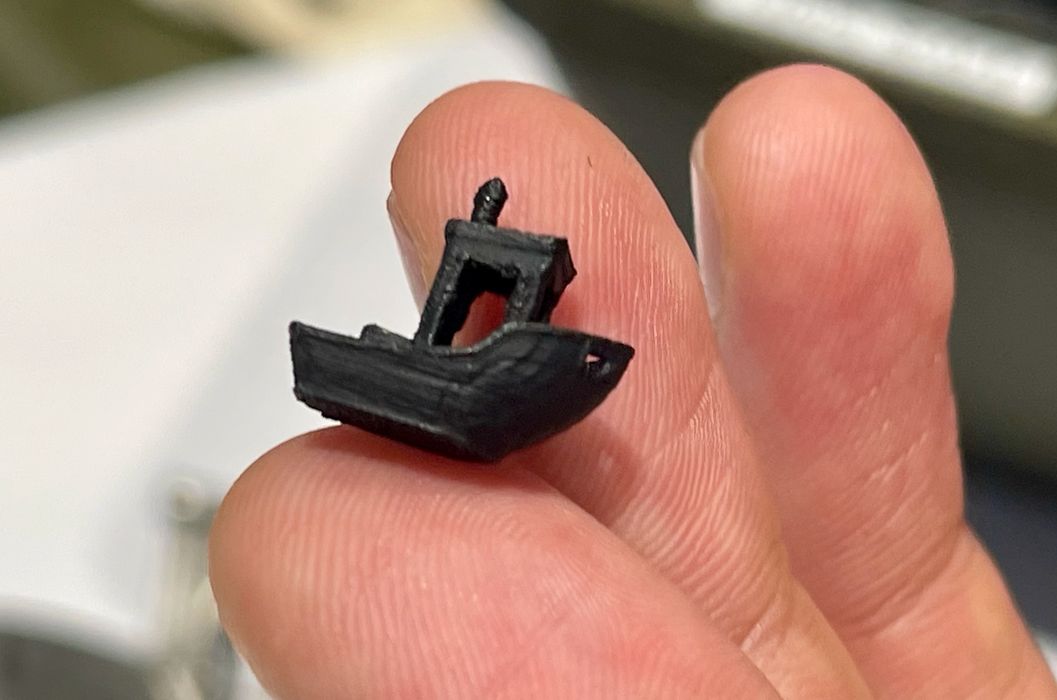

But that doesn’t mean the EVO can’t handle smaller, more precise prints. Here we see a miniature #3DBenchy successfully produced on the same EVO machine.

Creative 3D has put considerable time into refining the components and tuning of the EVO to enable both high speed printing and the achievement of excellent print quality. Here you can see a large vase produced on the EVO. While it might not be apparent in our image, this item had exceptionally good surface quality.

Much of the high speed printing capability is due to the design of the large motion system, added to the complex extruder / hot end seen above. The hot end can also accept different nozzle sizes ranging from 0.25mm to 2.0mm, the larger of which would be useful for larger prints. The printhead is designed for easy maintenance and can be quickly changed if required. But if you do swap toolheads, the EVO can automatically recognize which type is installed and act accordingly.

The machine should be available from Creative 3D, with a list price of around US$25,000 for an assembled unit.

Via Creative 3D