There’s a reason the word “nano” appears in Nano Dimension’s company name.

The Israeli company has been in the news over the past year primarily due to a series corporate acquisitions and attempts to add even more companies, but today we’re looking at their foundational technology: nano 3D printing.

Most 3D printers produce objects that you can at least hold in your hand, while others produce huge building-sized objects. Nano Dimension’s Fabrica 3D printer line is neither of these: these machines can produce extremely small items.

How is this done? The Fabrica series uses a micro DLP process, which is able to provide extraordinary resolution well beyond that achievable by most other 3D printing processes. However, the machines that implement this process are typically quite small in build volume, and thus they are ideal for making very small but complex parts.

Nano Dimension offers four variants of the Fabrica 3D printer, the Tera 250vx, Tera 25vx, Giga 250vx and Giga 25vx. Each has a different combination of maximum resolution and build volume, with the Tera series having a much larger build volume of 50 x 50 x 100 mm. The Giga series’ build volume is either 12 x 18 x 45 mm, or a very tiny 6 x 9 x 45 mm.

If those build volumes sound small, it’s because these machines can 3D print tiny objects in very fine resolution. Systems offer 0.0076 or 0.0038 mm resolution, which is so small you cannot see the details without professional optical aids.

Not only are the prints small and of fine detail, but Nano Dimension also offers a very wide range of resin materials for use in the Fabrica line. Recently they introduced several new materials, including a high thermal material for mechanical applications, a flexible material and a new material certified for medical use.

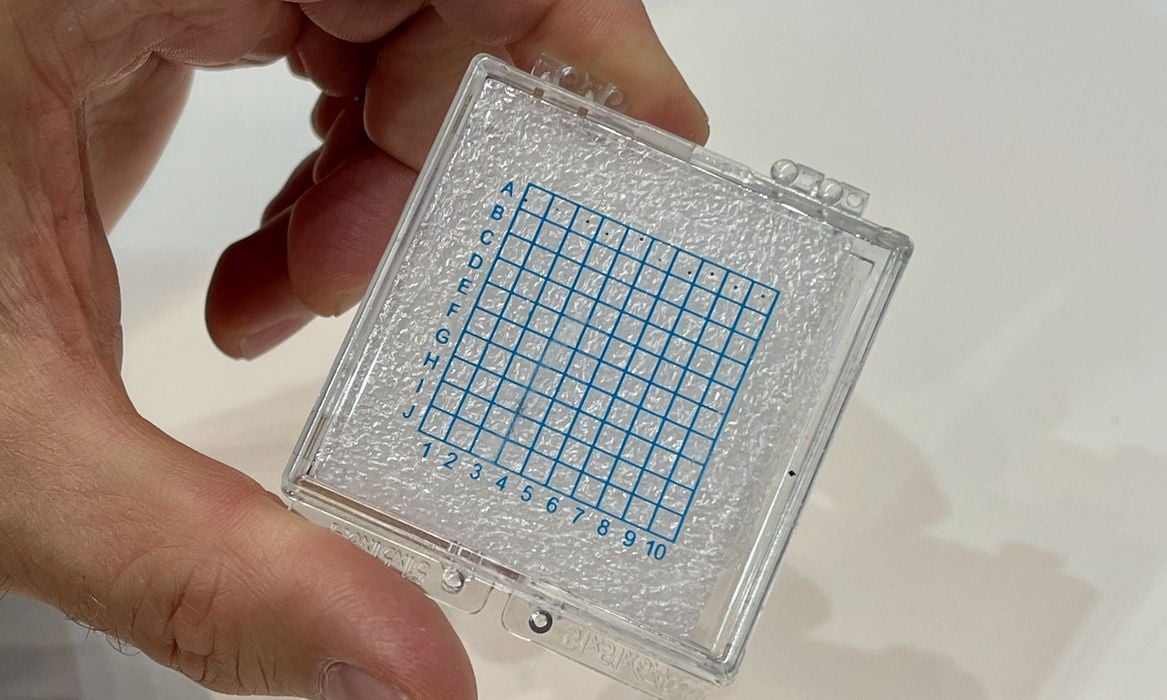

How tiny are these prints? Take a look at the top image, where you can see a series of 3D prints made on the Fabrica system by Nano Dimension. Wait, you can’t see them?

They are those barely visible tiny black dots in the cells of the holder. Those are indeed 3D prints!

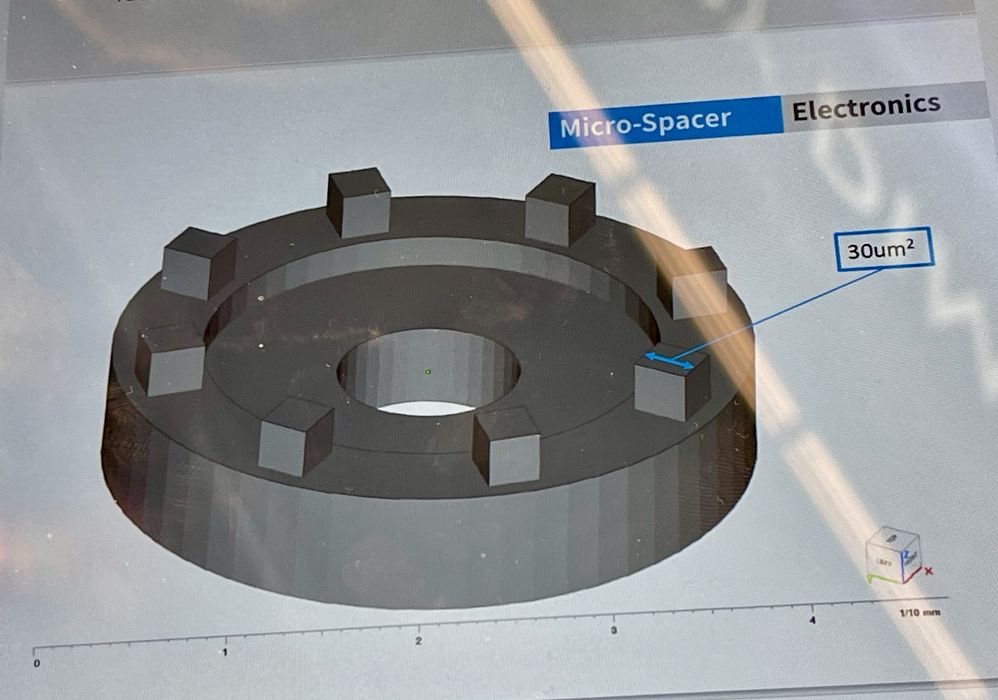

What are they, exactly? Here’s a picture of the 3D model used for those prints. It’s actually a microscopic spacer for a very tiny component.

This is an incredible capability and allows manufacturers to realize extraordinarily small designs. One can imagine the possibilities of nearly invisible machines able to perform useful tasks.

Via Nano Dimension